Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Poultry Offal Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Poultry Offal Worker so you can tailor your answers to impress potential employers.

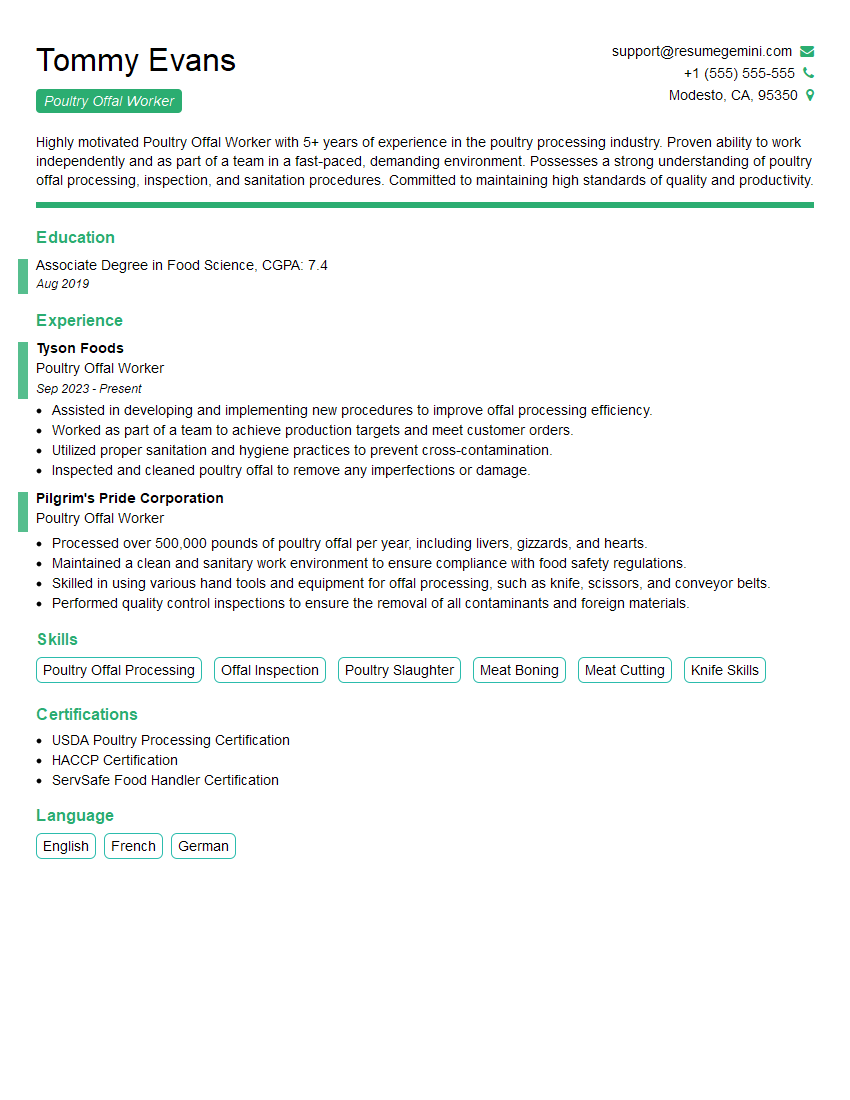

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Poultry Offal Worker

1. What are the different types of poultry offal and how do you process each type?

- Evisceration: Removing the internal organs from the bird.

- Scalding: Submerging the bird in hot water to loosen the feathers.

- De-feathering: Removing the feathers from the bird using a mechanical plucker.

- Head removal: Removing the head from the bird.

- Foot removal: Removing the feet from the bird.

- Giblet removal: Removing the giblets (heart, liver, gizzard) from the bird.

2. What are the different ways to package poultry offal and what are the pros and cons of each method?

Vacuum Packing:

- Pros: Extends shelf life, prevents contamination.

- Cons: Can be expensive, requires specialized equipment.

Modified Atmosphere Packaging (MAP):

- Pros: Extends shelf life, reduces spoilage, maintains product quality.

- Cons: Requires specialized equipment and gases.

Cryovac:

- Pros: Extends shelf life, reduces freezer burn, maintains product quality.

- Cons: Requires specialized equipment and materials.

3. What are the different types of equipment used in poultry offal processing and what are their functions?

- Eviscerating machines: Remove internal organs from the bird.

- Scalding tanks: Submerge the bird in hot water to loosen the feathers.

- Feather pluckers: Remove the feathers from the bird.

- Head and foot removers: Remove the head and feet from the bird.

- Giblet removers: Remove the giblets from the bird.

4. What are the different food safety regulations that apply to poultry offal processing and how do you ensure compliance?

- HACCP (Hazard Analysis and Critical Control Points): Identify and control hazards in the production process.

- GMP (Good Manufacturing Practices): Establish and maintain sanitary conditions in the processing facility.

- SSOP (Sanitation Standard Operating Procedures): Detail specific procedures for cleaning and sanitation.

5. What are the different ways to improve the efficiency of poultry offal processing and what are the potential benefits of each method?

- Automating processes: Using machines to perform tasks such as evisceration and de-feathering.

- Streamlining production lines: Optimizing the flow of materials and workers to reduce bottlenecks.

- Implementing lean manufacturing principles: Reducing waste, improving quality, and increasing productivity.

6. What are the different types of waste generated by poultry offal processing and how do you dispose of each type?

- Solid waste: Feathers, heads, feet, giblets.

- Liquid waste: Blood, wash water.

- Hazardous waste: Chemicals, cleaning agents.

7. What are the different types of maintenance tasks that need to be performed on poultry offal processing equipment and how often should each type of task be performed?

- Daily: Cleaning and inspecting equipment.

- Weekly: Lubricating equipment.

- Monthly: Calibrating equipment.

- Quarterly: Overhauling equipment.

8. What are the different types of training that you have received in poultry offal processing and what are the key skills that you have learned from each type of training?

- HACCP training: Learned about food safety principles and how to implement them in a processing facility.

- GMP training: Learned about sanitary practices and how to maintain a clean processing facility.

- Equipment training: Learned about the different types of equipment used in poultry offal processing and how to operate and maintain them.

9. What are the different types of challenges that you have faced in poultry offal processing and how have you overcome them?

- Equipment breakdowns: Troubleshoot and repair equipment.

- Food safety issues: Implement corrective actions to prevent and control foodborne illnesses.

- Production delays: Identify and resolve bottlenecks to improve efficiency.

10. What are your career goals in poultry offal processing and how do you plan to achieve them?

- Advance to a supervisory or management position.

- Develop new and innovative ways to improve efficiency and reduce costs.

- Become an expert in poultry offal processing and share my knowledge with others.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Poultry Offal Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Poultry Offal Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Poultry Offal Workers are responsible for a variety of tasks in the poultry processing industry. These tasks include:

1. Offal Separation

Separating inedible offal from edible poultry products, including the removal of organs, intestines, and other waste materials.

2. Cleaning and Preparation

Cleaning and preparing offal for further processing, such as trimming, cutting, and sorting.

3. Packaging and Storage

Packaging and storing offal in accordance with food safety standards.

4. Sanitation and Hygiene

Maintaining a clean and hygienic work area to prevent contamination of poultry products.

- Adhering to strict sanitation and hygiene guidelines.

- Using personal protective equipment, such as gloves and hairnets.

- Ensuring that all surfaces and equipment are thoroughly cleaned and sanitized.

Interview Tips

Preparing for an interview for a Poultry Offal Worker position is essential to showcase your skills and increase your chances of success.

1. Research the Company and Position

Take the time to research the poultry processing company and the specific Poultry Offal Worker position you are applying for. This will help you understand the company’s values, culture, and expectations for the role.

- Visit the company’s website to learn about their history, mission, and products.

- Read industry news and articles to stay up-to-date on trends and best practices in poultry processing.

- Review the job description carefully to identify the key responsibilities and qualifications required for the position.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and during the interview. Focus on your abilities in offal separation, cleaning, preparation, and sanitation.

- Quantify your accomplishments whenever possible. For example, instead of simply stating that you have experience in offal separation, you could say that you have “separated over 100,000 pounds of offal per day.”

- Be prepared to discuss your knowledge of poultry processing regulations and food safety standards.

- If you have any experience in other areas of poultry processing, such as slaughter or packaging, be sure to mention it.

3. Demonstrate Your Work Ethic and Attitude

Poultry Offal Workers are expected to be reliable, hard-working, and able to work in a fast-paced environment. Be sure to convey these qualities in your interview.

- Be on time for your interview and dress appropriately.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be prepared to answer questions about your work ethic and how you handle challenges.

4. Prepare Common Interview Questions

There are several common interview questions that you are likely to be asked, such as:

- “Tell me about your experience in poultry processing.”

- “What are your strengths and weaknesses as a Poultry Offal Worker?”

- “Why are you interested in working for our company?”

- “What are your salary expectations?”

- “Do you have any questions for me?”

Take the time to prepare thoughtful answers to these questions in advance.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Poultry Offal Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.