Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Poultry Picker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

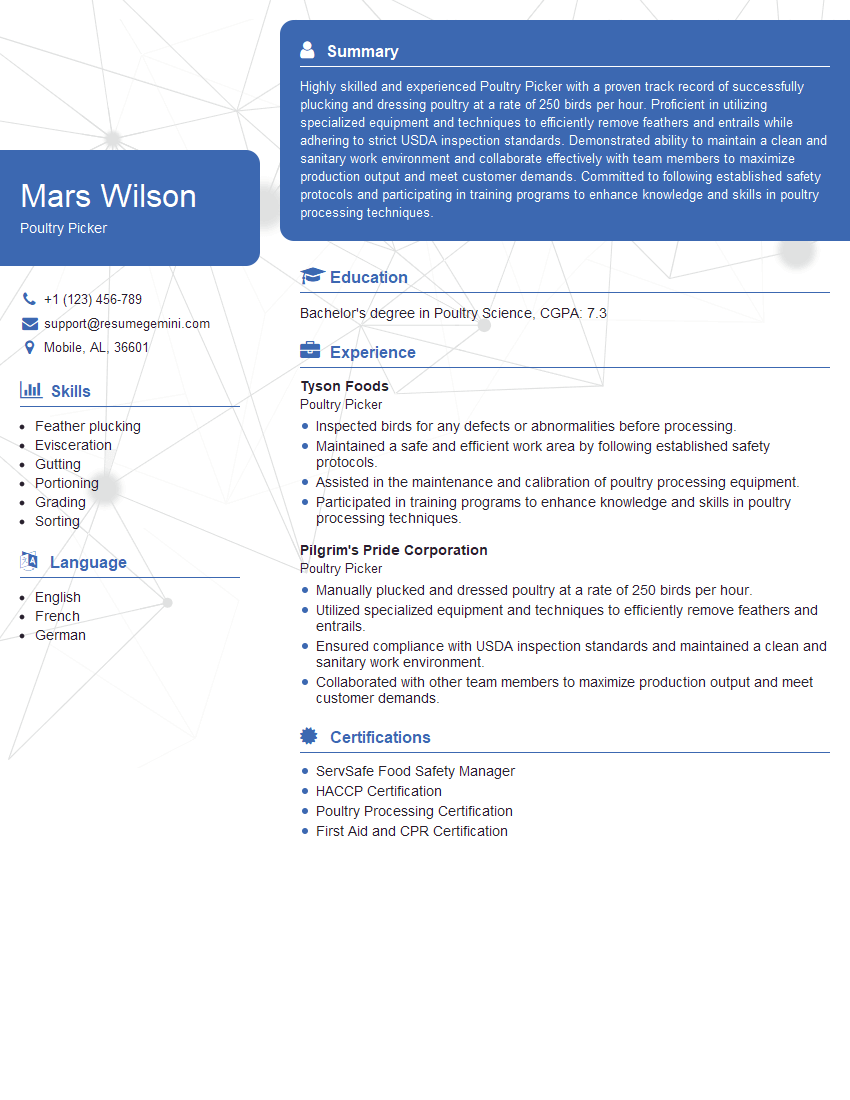

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Poultry Picker

1. Can you explain the process of poultry picking?

Poultry picking involves removing the feathers from poultry carcasses to prepare them for further processing or consumption. The process typically includes scalding, picking, and finishing.

- Scalding: Poultry carcasses are submerged in hot water (typically 120-130°F) for a controlled period to loosen the feathers.

- Picking: The loosened feathers are removed using mechanical pickers, which have rotating rubber fingers that gently agitate the carcass to detach the feathers.

- Finishing: Any remaining feathers or pin feathers are manually removed using tweezers or other tools to ensure a clean and presentable carcass.

2. What are the different types of poultry pickers and their advantages?

Disk Pickers

- Consist of multiple rubber discs that rotate at high speed against the carcass.

- Efficient and effective for removing feathers from larger poultry, such as turkeys.

Drum Pickers

- Feature a rotating drum with rubber fingers that contact the carcass.

- Suitable for picking smaller poultry, such as chickens and ducks.

Rotary Pin Pickers

- Use rotating pins to agitate the carcass and loosen the feathers.

- Ideal for finishing and removing pin feathers from already picked birds.

3. How do you ensure the quality of poultry picking?

- Proper scalding: Accurate temperature and duration control to loosen feathers without damaging the skin.

- Efficient picking: Optimizing picker settings to remove feathers effectively while minimizing carcass damage.

- Careful finishing: Meticulous manual removal of any remaining feathers to ensure a clean appearance.

- Sanitation: Regular cleaning and disinfection of equipment to prevent contamination and maintain hygiene standards.

4. What are the key maintenance procedures for poultry pickers?

- Regular cleaning: Removing feather debris and other contaminants from the equipment.

- Rubber finger inspection and replacement: Checking for wear and tear and replacing damaged or worn fingers to maintain picking efficiency.

- Lubrication: Ensuring that moving parts are properly lubricated to prevent friction and extend equipment life.

- Preventive maintenance: Scheduled inspections and adjustments to avoid breakdowns and ensure optimal performance.

5. How do you troubleshoot common problems with poultry pickers?

- Poor feather removal: Inspect rubber fingers for damage or wear, check scalding parameters, and adjust picker settings.

- Carcass damage: Reduce picker agitation or adjust carcass positioning to minimize bruising or skin tears.

- Equipment overheating: Ensure proper lubrication, check motor and drive components, and inspect electrical connections.

- Excessive water usage: Check for leaks in the scalding system, adjust water flow, and monitor temperature to avoid unnecessary water loss.

6. What are the safety precautions to observe when operating poultry pickers?

- Wear appropriate protective gear, including gloves, apron, and safety glasses.

- Keep equipment guards in place and ensure all moving parts are fully enclosed.

- Handle carcasses with care to avoid slipping or injury.

- Be aware of potential electrical hazards and follow proper lockout/tagout procedures.

7. How do you maintain a clean and sanitary work environment in the poultry picking area?

- Regularly clean and disinfect all equipment, including pickers, scalding tanks, and conveyors.

- Implement effective drainage and waste removal systems to prevent buildup and contamination.

- Train staff on proper sanitation procedures and enforce hygiene standards.

- Monitor temperature and humidity to control the growth of bacteria.

8. What are the different feather grades and how do they affect the value of the poultry carcass?

- Grade A: No visible feathers or pin feathers, clean and well-picked carcasses.

- Grade B: Some pin feathers or small feather fragments present, but no major feather coverage.

- Grade C: Noticeable feather coverage, but still marketable for further processing.

- Grade D: Excessive feather coverage, unsuitable for retail sale or further processing without extensive re-picking.

9. What are some innovations or advancements in poultry picking technology?

- Automated carcass handling systems to improve efficiency and reduce manual labor.

- Optical grading systems to automatically classify feather grades and sort carcasses.

- Water-saving technologies to reduce water consumption in scalding and picking processes.

- Antimicrobial coatings and treatments to enhance equipment sanitation.

10. How do you stay updated with the latest industry trends and best practices in poultry picking?

- Attend industry conferences and trade shows.

- Read trade publications and research journals.

- Network with other poultry processors and equipment manufacturers.

- Seek training and certification opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Poultry Picker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Poultry Picker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Poultry Pickers are responsible for the efficient and sanitary removal of feathers from poultry carcasses. They work in a fast-paced environment and may be required to work long hours. Key job responsibilities include:

1. Poultry Handling

Handling live poultry with care and ensuring their welfare.

- Catching and shackling live birds

- Hanging birds on the processing line

2. Feather Removal

Operating poultry picking machines to remove feathers from carcasses.

- Adjusting machine settings to ensure optimal feather removal

- Monitoring the picking process and making necessary adjustments

3. Carcass Inspection

Inspecting carcasses for any remaining feathers or other defects.

- Identifying and removing any remaining feathers by hand

- Trimming carcasses to remove any excess skin or fat

4. Sanitation and Hygiene

Maintaining a clean and sanitary work environment.

- Cleaning and disinfecting work surfaces and equipment

- Adhering to all food safety regulations

Interview Tips

Preparing for an interview for a Poultry Picker position requires understanding the key job responsibilities and tailoring your answers to demonstrate your relevant skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Learn about the company’s history, values, and products. Research the poultry industry to understand the latest trends and challenges.

- Visit the company website

- Read industry news and articles

2. Highlight Relevant Skills and Experience

Emphasize your experience in poultry handling, feather removal, and carcass inspection. Quantify your accomplishments whenever possible.

- Use specific examples to demonstrate your skills

- Describe how you have contributed to improving efficiency or quality

3. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about your experience in poultry processing.

- How do you ensure the quality of your work?

- What are your strengths and weaknesses as a Poultry Picker?

4. Demonstrate Teamwork and Safety Awareness

Poultry picking is a team-oriented environment. Highlight your ability to work effectively with others and your commitment to safety.

- Describe situations where you have worked successfully as part of a team

- Explain how you prioritize safety in your work

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive at the interview on time. Your appearance and punctuality show respect for the interviewer and the company.

- Choose clean and appropriate clothing

- Plan your route and allow extra time for unexpected delays

Next Step:

Now that you’re armed with the knowledge of Poultry Picker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Poultry Picker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini