Are you gearing up for an interview for a Poured Concrete Wall Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Poured Concrete Wall Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

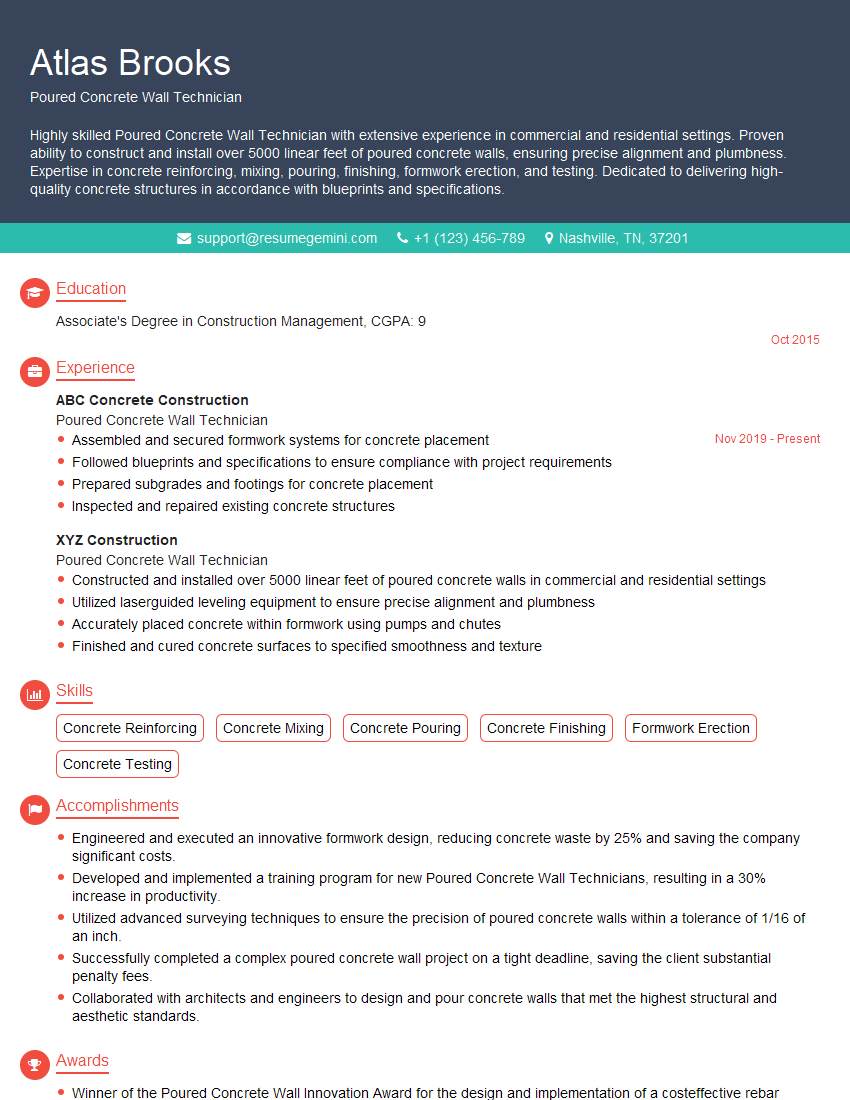

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Poured Concrete Wall Technician

1. Explain the process of preparing the site for a poured concrete wall?

The process of preparing the site for a poured concrete wall involves several steps to ensure a solid foundation and proper execution:

- Clearing the area: Remove any vegetation, debris, or obstacles from the site.

- Excavation: Dig the foundation trench to the specified depth and width, ensuring proper drainage.

- Formwork installation: Set up formwork panels to define the shape and size of the wall, ensuring they are level and braced securely.

- Reinforcement placement: Install reinforcing bars or wire mesh within the formwork to provide structural strength to the concrete.

- Subgrade preparation: Level and compact the soil or gravel base to create a stable surface for the concrete.

2. What are the key factors to consider when selecting the appropriate concrete mix for a poured concrete wall?

Strength requirements:

- The concrete’s compressive strength must meet the structural demands of the wall.

- Walls subjected to heavy loads or environmental stresses require higher-strength concrete.

Workability:

- Concrete should be workable enough to be placed and consolidated effectively within the formwork.

- Factors like slump, air content, and aggregate size influence workability.

Durability:

- Concrete should resist deterioration due to exposure to weather, chemicals, or wear and tear.

- Additives or special mix designs can enhance durability.

3. Describe the curing process for a poured concrete wall and its importance?

Curing is a crucial process that involves keeping the concrete moist and protected to allow it to gain strength and develop its desired properties:

- Moist curing: Sprinkle water or use curing compounds to keep the concrete surface damp, preventing rapid moisture loss.

- Duration: Curing should continue for a minimum of 7 days, or longer in cooler temperatures.

- Importance: Proper curing ensures optimal strength development, reduces cracking, and enhances the concrete’s overall durability.

4. How do you ensure that the concrete wall is plumb and level during the pouring process?

Maintaining plumb and level during the pouring process is essential for structural integrity and aesthetics:

- Formwork alignment: Check the formwork panels for verticality and levelness before pouring.

- Plumb indicators: Use plumb lines or laser levels to monitor the formwork and adjust as needed.

- Screeds or guides: Set up screeds or guides on top of the formwork to control the concrete level.

- Continuous monitoring: Regularly check and adjust the concrete level as it is being poured.

5. What techniques can you employ to minimize cracking in a poured concrete wall?

Minimizing cracking is crucial for maintaining the structural integrity and aesthetic appeal of the wall:

- Proper curing: Ensure adequate curing to prevent shrinkage cracking.

- Expansion joints: Install expansion joints to accommodate movement due to temperature changes.

- Control joints: Create weakened planes in the concrete to induce cracking in predetermined locations, reducing random cracking.

- Adequate reinforcement: Provide sufficient reinforcement to resist tensile stresses that can lead to cracking.

6. Explain the steps involved in finishing the surface of a poured concrete wall?

Finishing the surface of a poured concrete wall involves several steps to achieve the desired texture and appearance:

- Stripping formwork: Remove the formwork once the concrete has gained sufficient strength.

- Cleaning: Clean the concrete surface to remove any debris or laitance.

- Floating: Use a trowel to smooth and level the surface, creating a uniform texture.

- Troweling: Apply additional troweling to achieve the desired smoothness or texture.

- Curing: Continue curing the concrete surface to ensure proper hydration and strength development.

7. What are the different types of finishes that can be applied to a poured concrete wall and their characteristics?

Various finishes can be applied to poured concrete walls, each with its own characteristics:

- Smooth finish: A troweled finish that creates a smooth and even surface.

- Broom finish: A textured finish created by dragging a broom across the fresh concrete.

- Exposed aggregate finish: A finish that reveals the coarse aggregates in the concrete, creating a decorative and textured surface.

- Stamped finish: A finish that imprints patterns or designs into the fresh concrete.

8. How do you determine the appropriate thickness for a poured concrete wall based on its function and structural requirements?

Determining the appropriate thickness of a poured concrete wall involves considering several factors:

- Structural loads: The wall must be thick enough to withstand the weight it supports and any lateral forces.

- Building code requirements: Local building codes specify minimum wall thicknesses based on the wall’s height and use.

- Insulation needs: Thicker walls can provide better insulation, reducing energy consumption.

- Architectural considerations: The desired aesthetics and proportions of the wall may influence its thickness.

9. What are the safety precautions that must be taken when working with poured concrete?

Working with poured concrete requires adherence to safety precautions to prevent accidents and ensure a safe work environment:

- Personal protective equipment: Wear appropriate clothing, gloves, eye protection, and respiratory protection.

- Wet concrete handling: Avoid direct contact with wet concrete as it can cause skin irritation and burns.

- Fall hazards: Be aware of potential fall hazards when working on elevated surfaces.

- Heavy equipment operation: Follow proper procedures and use caution when operating concrete mixers and other heavy equipment.

10. Describe your experience in troubleshooting problems that may occur during the pouring and finishing process?

Troubleshooting problems during the pouring and finishing process is crucial to ensure a successful outcome:

- Cold joints: Identify areas where concrete has set before the next section is poured and take measures to prevent cold joints.

- Cracking: Diagnose the cause of cracks and implement appropriate repair methods.

- Honeycombing: Address areas where coarse aggregates have settled, leaving voids in the concrete.

- Discoloration: Identify the cause of discoloration and determine appropriate solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Poured Concrete Wall Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Poured Concrete Wall Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Poured Concrete Wall Technician, you will be responsible for ensuring the proper preparation, placement, and finishing of concrete walls in various construction projects. Your key responsibilities will include:

1. Preparation and Layout

Accurately marking and laying out the walls based on blueprints and specifications.

- Setting formwork and installing reinforcement steel according to plans.

- Checking for proper grade and ensuring a level base.

2. Concrete Placement

Operating concrete pumps and placing concrete into formwork, ensuring proper consolidation.

- Monitoring concrete levels and adjusting flow rates to prevent overfilling or under filling.

- Verifying the concrete’s consistency, slump, and air content.

3. Finishing and Curing

Smoothing and finishing concrete surfaces using screeds, bull floats, and power trowels.

- Applying curing compounds to protect and strengthen the concrete.

- Inspecting the finished walls for imperfections and addressing any issues.

4. Safety and Quality Control

Adhering to all safety regulations and wearing appropriate personal protective equipment (PPE).

- Maintaining a clean work area and organizing materials properly.

- Inspecting completed walls for quality and ensuring compliance with specifications.

Interview Tips

Preparing for an interview for a Poured Concrete Wall Technician position can help you make a strong impression and increase your chances of success. Here are some interview tips to help you ace your interview:

1. Research the Company and Position

Thoroughly research the company you are applying to, including their website, social media pages, and industry news. Understand the specific requirements of the position and how your skills and experience align with them.

- Identify the company’s values and mission to demonstrate your alignment with their goals.

- Read industry publications and relevant articles to stay up-to-date on the latest techniques and best practices.

2. Practice Your Answers to Common Interview Questions

Anticipate questions related to your concrete experience, technical skills, and safety knowledge. Practice answering them clearly and concisely, highlighting your qualifications and abilities.

- Prepare examples of projects where you successfully implemented concrete wall techniques.

- Discuss your knowledge of concrete materials, additives, and reinforcement methods.

3. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview. Arrive on time to demonstrate punctuality and respect for the interviewer’s schedule.

- Consider wearing clean coveralls or work clothes if appropriate for the company culture.

- Be prepared with a portfolio or resume that showcases your experience and certifications.

4. Be Enthusiastic and Ask Questions

Show enthusiasm for the position and the concrete industry. Ask thoughtful questions that demonstrate your interest in the company and the role.

- Inquire about the company’s current projects and their plans for future growth.

- Ask about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Poured Concrete Wall Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!