Are you gearing up for an interview for a Powder and Primer Canning Leader position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Powder and Primer Canning Leader and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

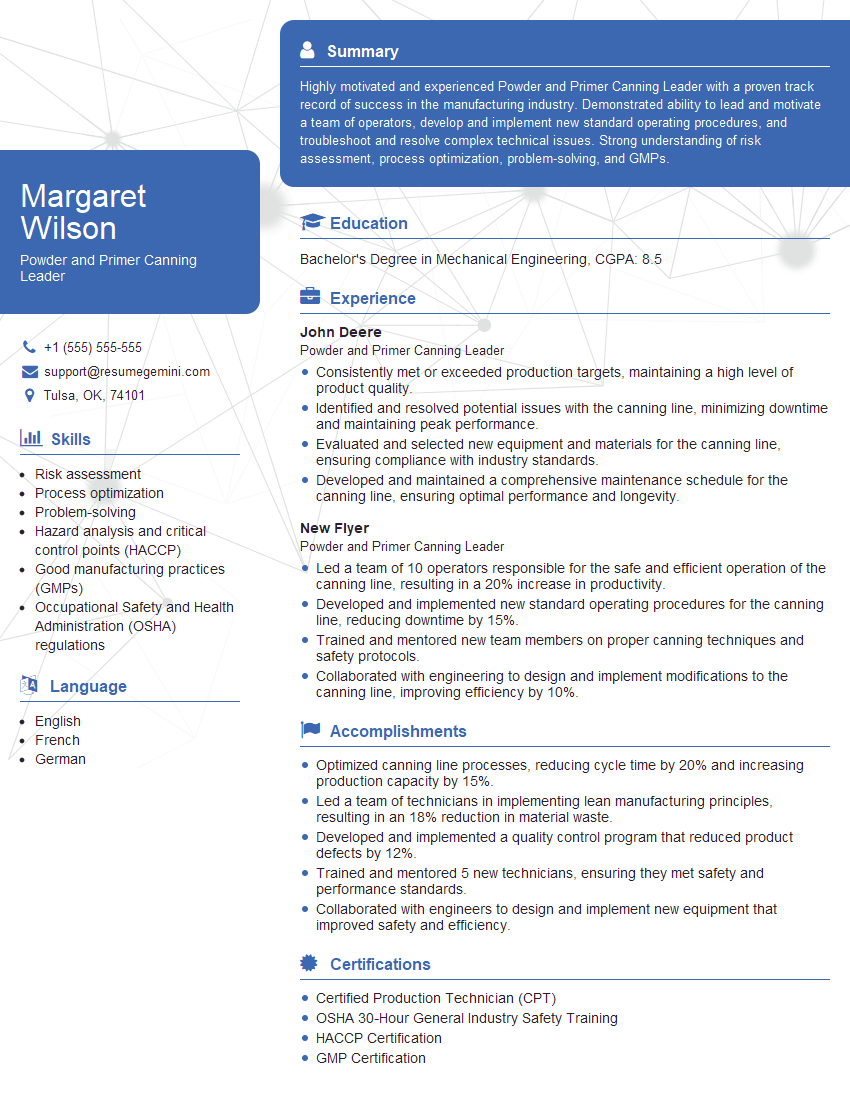

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Powder and Primer Canning Leader

1. Describe the key responsibilities of a Powder and Primer Canning Leader.

As a Powder and Primer Canning Leader, I will be responsible for:

- Supervising and managing a team of production operators

- Ensuring that all production processes are carried out safely and efficiently

- Maintaining a clean and organized work area

- Monitoring production quality and taking corrective action as needed

- Training and developing new employees

2. What are the most important safety protocols to follow when working in a powder and primer canning facility?

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures

- Being aware of potential hazards and taking appropriate precautions

- Reporting any unsafe conditions or practices to a supervisor

- Receiving regular safety training

3. What are the different types of powder and primer canning equipment, and how do they work?

- Canning machines: These machines fill and seal cans with powder and primer.

- Depalletizers: These machines remove cans from pallets and place them on the canning line.

- Palletizers: These machines remove cans from the canning line and place them on pallets.

- Conveyors: These machines transport cans throughout the canning process.

- Mixers: These machines mix powder and primer to create a homogeneous mixture.

4. What are the most common quality defects that can occur in powder and primer canning, and how can they be prevented?

- Dents and scratches: These can be caused by improper handling or storage of cans.

- Leaks: These can be caused by improper sealing of cans.

- Contamination: This can be caused by foreign objects getting into the powder or primer.

- Incorrect fill weight: This can be caused by improper calibration of the canning machine.

5. How do you ensure that powder and primer are properly stored and handled?

- Powder and primer should be stored in a cool, dry place.

- Containers should be properly labeled and sealed.

- Powders and primers should be handled with care to avoid creating dust or spills.

- Spills should be cleaned up immediately.

- Powder and primer should be disposed of properly.

6. What are the most important maintenance tasks that need to be performed on powder and primer canning equipment?

- Regularly cleaning and inspecting equipment.

- Lubricating moving parts.

- Checking and adjusting belts and chains.

- Replacing worn or damaged parts.

- Calibrating equipment to ensure accuracy.

7. How do you manage a team of production operators?

- Set clear expectations and goals.

- Provide regular feedback and coaching.

- Delegate tasks and responsibilities.

- Empower employees to make decisions.

- Create a positive and supportive work environment.

8. How do you motivate and engage your team?

- Recognize and reward employee achievements.

- Provide opportunities for professional development.

- Create a sense of community and belonging.

- Empower employees to take ownership of their work.

- Celebrate team successes.

9. How do you handle conflict and resolve disputes within your team?

- Address conflicts promptly and directly.

- Listen to all sides of the story.

- Help disputing parties to understand each other’s perspectives.

- Work together to find a mutually acceptable solution.

- Follow up to ensure that the conflict has been resolved.

10. What are your career goals and aspirations?

My career goal is to become a Production Manager in the manufacturing industry. I am confident that my skills and experience in powder and primer canning will provide me with a solid foundation for success in this role. I am eager to take on new challenges and responsibilities, and I am confident that I can make a significant contribution to any organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Powder and Primer Canning Leader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Powder and Primer Canning Leader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Powder and Primer Canning Leaders are crucial in the manufacturing process of ammunition. Their primary responsibility is to oversee the efficient and safe operation of powder and primer canning lines, ensuring the production of high-quality ammunition components.

1. Production Management

A Powder and Primer Canning Leader is accountable for ensuring that production operates at optimal levels. Key responsibilities within this domain include:

- Monitor and adjust production schedules to meet deadlines

- Oversee the setup, operation, and maintenance of powder and primer canning machinery

- Troubleshoot and resolve production issues to minimize downtime

- Maintain accurate production records and reports

2. Quality Control

Quality is of paramount importance in ammunition manufacturing. A Powder and Primer Canning Leader is responsible for ensuring that products meet stringent quality standards:

- Conduct regular inspections of powder and primers to verify quality and compliance

- Monitor process parameters and make adjustments as necessary to maintain quality

- Review and analyze quality data to identify potential issues

- Coordinate with quality assurance personnel to resolve quality-related issues

3. Safety and Environmental Compliance

The handling of powders and primers requires strict adherence to safety protocols and environmental regulations:

- Ensure compliance with all safety regulations and procedures

- Train and supervise staff on safe work practices

- Conduct regular safety audits and inspections

- Monitor and control environmental parameters to maintain a safe and compliant work environment

4. Team Management and Leadership

Effective leadership and teamwork are crucial in a production environment:

- Lead and motivate a team of operators

- Provide training and development opportunities for team members

- Foster a positive and collaborative work environment

- Communicate effectively with team members, supervisors, and other departments

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Consider the following tips to ace your interview for a Powder and Primer Canning Leader position:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Research the specific role and responsibilities of the Powder and Primer Canning Leader position to demonstrate your understanding and interest.

2. Highlight Relevant Experience and Skills

Emphasize your experience in production management, quality control, safety compliance, and team leadership. Quantify your accomplishments with specific examples to showcase your impact and contributions.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Practice your answers to articulate your strengths and how they align with the position’s requirements.

4. Prepare Industry-Specific Questions

Research industry trends and challenges related to powder and primer canning. Demonstrate your knowledge and insights by asking thoughtful questions that show you’re engaged in the field.

5. Present Yourself Professionally

Dress appropriately, arrive on time, and maintain a professional demeanor throughout the interview. Your appearance and conduct reflect your interest and respect for the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Powder and Primer Canning Leader interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!