Feeling lost in a sea of interview questions? Landed that dream interview for Powder Blender and Pourer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Powder Blender and Pourer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

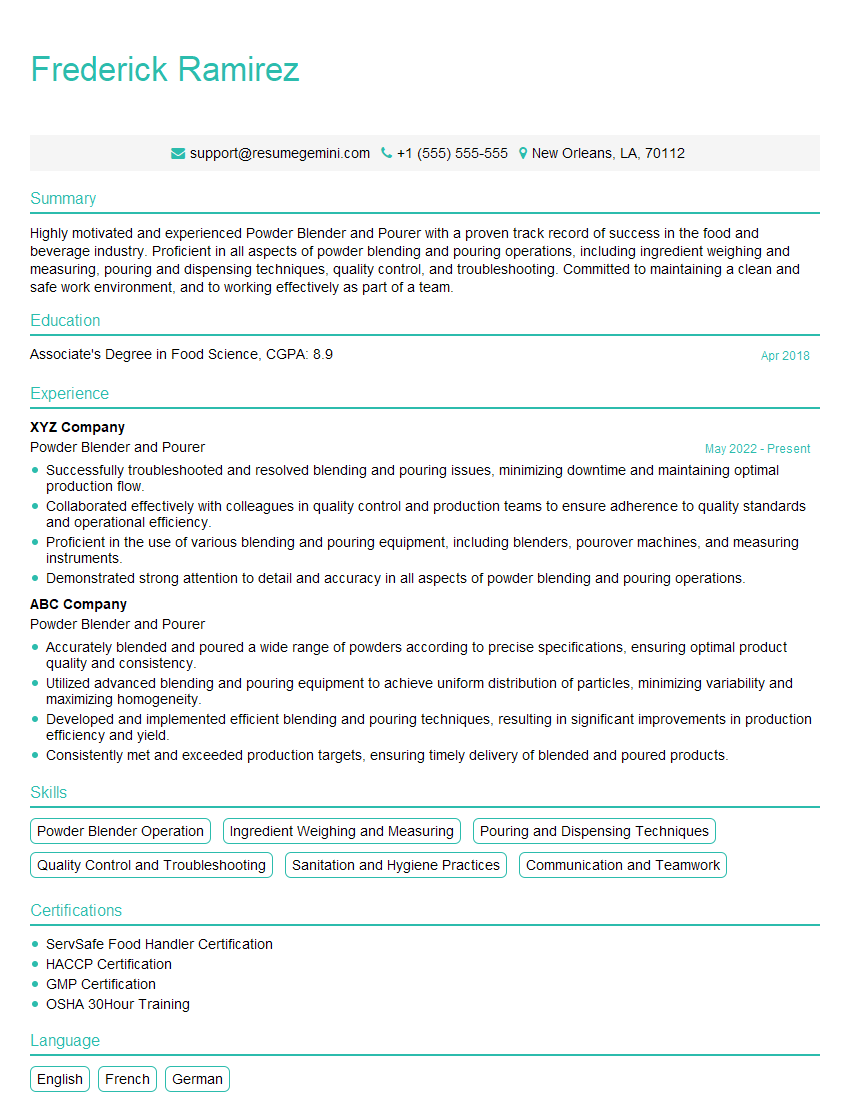

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Powder Blender and Pourer

1. Describe the process of blending powders?

The process of blending powders involves several steps:

- Selecting compatible powders: Ensure the powders are compatible chemically and physically.

- Determining blend ratio: Calculate the desired proportions of each powder based on the required blend specification.

- Preparing powders: Pre-process powders by sieving, drying, or agglomerating as necessary for optimal blending.

- Choosing appropriate blender: Select the blender type (e.g., V-blender, ribbon blender, conical blender) based on the powder properties and blend requirements.

- Loading powders into blender: Carefully load the powders into the blender, ensuring uniform distribution and avoiding overfilling.

- Setting blending parameters: Adjust blending time and speed according to the blend characteristics and desired homogeneity.

- Mixing powders: Operate the blender to achieve the desired level of homogeneity, ensuring complete mixing and avoiding segregation.

- Sampling and testing: Take samples from the blended powder to evaluate homogeneity and confirm adherence to specifications.

2. What are the different types of blenders used for powder blending?

Types of blenders:

- V-blender: Suitable for gentle mixing of fragile powders, with a V-shaped container that rotates to lift and cascade powders.

- Ribbon blender: Effective for blending powders with different densities or particle sizes, with a U-shaped container and rotating agitators that move powders along its length.

- Conical blender: Suitable for large-scale blending, with a conical container that rotates and tumbles powders, creating a vortex for thorough mixing.

- Turbula blender: Designed for intensive mixing of small batches, with a rotating container that moves powders in a three-dimensional motion.

- Paddle blender: Used for blending powders with varying flowability, with paddles or blades mounted on a rotating shaft that gently mix and blend the powders.

Factors influencing blender selection:

- Powder properties (e.g., density, particle size, flowability)

- Blend requirements (e.g., homogeneity level, batch size)

- Production environment (e.g., space constraints, operating costs)

3. How do you ensure the homogeneity of a blended powder?

Ensuring homogeneity involves:

- Proper powder preparation: Pre-processing powders optimizes their mixing behavior.

- Selecting compatible powders: Incompatible powders may resist uniform mixing.

- Blending at optimal parameters: Determine the appropriate blending time and speed for the specific powders and blender used.

- Regular sampling and testing: Take samples throughout the blending process to monitor homogeneity and make adjustments as needed.

- Cycle blending: Repeat the blending process multiple times to achieve a higher level of homogeneity.

- Using statistical methods: Employ statistical techniques to analyze the distribution of components in the blended powder and ensure uniformity.

4. How do you handle powders with poor flowability during blending?

Handling poorly flowing powders requires:

- Improving powder flowability: Use techniques such as pre-blending with a small amount of flow aid, adding anti-caking agents, or agglomerating the powders.

- Selecting appropriate blender: Choose a blender that can accommodate cohesive powders, such as a ribbon blender with low-shear agitators or a conical blender with a tumbling motion.

- Optimizing blending parameters: Adjust blending time, speed, and fill level to minimize powder compaction and promote uniform mixing.

- Using specialized equipment: Consider using blenders with fluidized bed technology or vacuum mixing capabilities to enhance powder flow and promote homogeneity.

5. What techniques can you use to prevent cross-contamination during powder blending?

Preventing cross-contamination involves:

- Cleaning and sanitation: Thoroughly clean the blender and all equipment before and after each use to eliminate residual powders.

- Segregated production: Dedicate blenders to specific products or use physical barriers to prevent cross-mixing.

- Color coding: Use different color-coded components or labels to distinguish between powders and avoid mix-ups.

- Validation procedures: Establish validation protocols to test for cross-contamination and ensure compliance with quality standards.

- Training and awareness: Educate operators on proper handling and storage procedures to minimize the risk of contamination.

6. How do you maintain the accuracy of powder dispensing equipment?

Maintaining dispensing accuracy involves:

- Regular calibration: Calibrate the dispensing equipment regularly using certified weights or volume standards.

- Routine maintenance: Perform preventive maintenance tasks, such as cleaning, lubrication, and inspection, to ensure proper functioning.

- Environmental control: Monitor and control environmental conditions (e.g., temperature, humidity) that can affect the accuracy of dispensing.

- Personnel training: Train operators on the proper use and maintenance of dispensing equipment to minimize errors.

- Statistical process control: Implement statistical process control techniques to monitor dispensing accuracy and identify any deviations from specifications.

7. What safety precautions should be observed when handling powders?

Safety precautions for powder handling include:

- Proper ventilation: Ensure adequate ventilation to prevent inhalation of airborne powders.

- Respiratory protection: Wear respirators or dust masks when handling powders that may release harmful or irritating particles.

- Protective clothing: Wear protective clothing, such as gloves, gowns, and eye protection, to minimize skin and eye contact.

- Proper storage: Store powders in sealed containers to prevent contamination and protect against moisture or other environmental factors.

- Spill control: Have spill containment measures in place to minimize the spread of powders in case of accidents.

- Emergency procedures: Establish emergency procedures for handling powder spills or accidents and train personnel on these procedures.

8. What troubleshooting techniques can you employ when encountering issues with powder blending or dispensing?

Troubleshooting techniques include:

- Identifying the root cause: Analyze the problem to determine its underlying causes, whether related to equipment, process parameters, or powder properties.

- Checking equipment: Inspect equipment components for wear, damage, or misalignment that may affect performance.

- Reviewing process parameters: Verify that blending parameters (e.g., blending time, speed) and dispensing settings are optimized for the specific powders being handled.

- Testing powder properties: Analyze powder characteristics, such as particle size distribution, flowability, and moisture content, to identify any factors contributing to blending or dispensing issues.

- Consulting with experts: Seek advice from technical experts or equipment manufacturers to gain insights and potential solutions.

9. How do you stay up-to-date with advancements in powder blending and dispensing technology?

To stay current with advancements:

- Attend industry conferences and exhibitions:

- Read technical journals and research papers:

- Network with professionals in the field:

- Explore online resources and webinars:

- Engage in continuing education programs:

10. How do you prioritize tasks and manage your time effectively in a fast-paced production environment?

Prioritizing and time management techniques:

- Setting clear priorities:

- Breaking down tasks:

- Delegating responsibilities:

- Using time management tools:

- Minimizing distractions:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Powder Blender and Pourer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Powder Blender and Pourer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Powder Blenders and Pourers play a crucial role in the production and packaging of various products, ensuring the efficient blending and dispensing of powdered materials. Their key job responsibilities include:

1. Material Handling and Preparation

Powder Blenders and Pourers are responsible for receiving, handling, and preparing powdered materials for blending.

- Inspect materials for quality and specifications

- Weigh and measure ingredients according to specified formulations

- Operate blending machines to ensure thorough mixing

2. Dispensing and Packaging

Once the powders are blended, Powder Blenders and Pourers dispense and package them accurately and efficiently.

- Calibrate and operate filling machines to fill containers

- Inspect and ensure filled containers meet quality standards

- Label containers with necessary product information

3. Equipment Maintenance and Calibration

To maintain optimal production, Powder Blenders and Pourers are responsible for the upkeep of equipment.

- Clean and maintain blending machines and filling lines

- Calibrate equipment regularly to ensure accuracy and precision

- Troubleshoot and resolve minor equipment malfunctions

4. Quality Control and Documentation

Adhering to quality standards is crucial in the role of Powder Blenders and Pourers.

- Monitor production processes to ensure compliance with specifications

- Maintain accurate records of blending and filling operations

- Inspect finished products to ensure consistency and quality

Interview Tips

To ace an interview for a Powder Blender and Pourer position, it is essential to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry. This knowledge will demonstrate your interest and understanding of the role.

- Visit the company’s website and read industry publications

- Connect with employees on LinkedIn to gain insights into the company culture

2. Highlight Relevant Skills and Experience

Emphasize your experience in powder handling, blending, and dispensing. Share specific examples of your work that showcase your skills and abilities.

- Quantify your accomplishments using metrics and data whenever possible

- Prepare examples of situations where you resolved challenges or improved processes

3. Demonstrate Attention to Detail and Quality

Powder Blenders and Pourers must be meticulous and detail-oriented. Highlight your strong attention to detail and commitment to quality.

- Explain your understanding of quality control procedures and standards

- Share examples of how you have contributed to improving product quality or reducing errors

4. Practice Common Interview Questions

Research typical interview questions for Powder Blenders and Pourers and practice your responses. This will help you articulate your skills and qualifications confidently.

- Prepare answers to questions about your experience, qualifications, and motivations

- Consider behavioral interview questions that ask you to describe specific work situations

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Powder Blender and Pourer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.