Are you gearing up for a career in Powder Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Powder Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

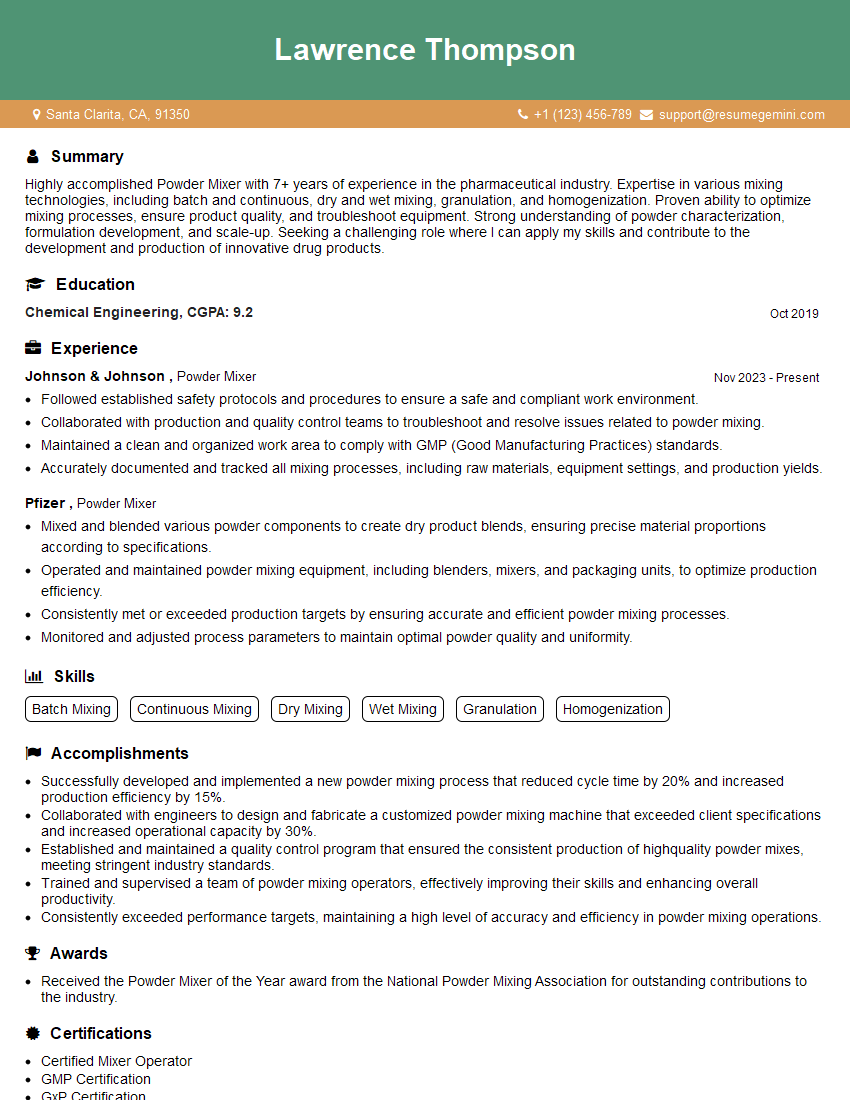

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Powder Mixer

1. Describe the types of powder mixers and their applications?

There are a variety of powder mixers, each with its own advantages and disadvantages. The most common types of powder mixers include:

- Ribbon Blender: This type of mixer is used for blending dry powders and granules. It consists of a horizontal cylindrical drum with a helical ribbon agitator that rotates inside the drum. The ribbon agitator helps to move the powder around and ensures that all of the ingredients are evenly mixed.

- Tumble Blender: This type of mixer is used for blending dry powders and granules. It consists of a horizontal cylindrical drum that rotates on its axis. The powder is tumbled inside the drum, and the tumbling action helps to mix the ingredients together.

- Cone Blender: This type of mixer is used for blending dry powders and granules. It consists of a conical-shaped drum that rotates on its axis. The powder is tumbled inside the drum, and the tumbling action helps to mix the ingredients together.

- Paddle Blender: This type of mixer is used for blending wet powders and pastes. It consists of a horizontal cylindrical drum with a paddle agitator that rotates inside the drum. The paddle agitator helps to move the powder around and ensures that all of the ingredients are evenly mixed.

- Nauta Mixer: This type of mixer is used for blending dry powders and granules. It consists of a vertical cylindrical drum with a helical screw agitator that rotates inside the drum. The screw agitator helps to move the powder around and ensures that all of the ingredients are evenly mixed.

2. What are the key factors to consider when selecting a powder mixer?

Factors to consider when selecting a powder mixer:

- Type of powder: The type of powder that you are mixing will determine the type of mixer that you need. Some mixers are designed for dry powders, while others are designed for wet powders or pastes.

- Batch size: The batch size that you need to mix will determine the size of the mixer that you need.

- Mixing time: The mixing time that you require will determine the type of mixer that you need. Some mixers are designed for fast mixing, while others are designed for slow mixing.

- Budget: The budget that you have available will determine the type of mixer that you can purchase.

Additional factors to consider:

- Ease of cleaning: The mixer should be easy to clean and maintain.

- Safety features: The mixer should have safety features, such as guards and interlocks, to protect the operator.

- Customer service: The manufacturer should provide good customer service, including technical support and spare parts.

3. How do you ensure that a powder mixer is properly maintained?

To ensure that a powder mixer is properly maintained, you should follow these steps:

- Regularly inspect the mixer for wear and tear.

- Clean the mixer after each use.

- Lubricate the mixer according to the manufacturer’s instructions.

- Calibrate the mixer regularly.

- Keep a maintenance log.

4. What are the common problems that can occur with powder mixers?

The following are some of the most common problems that can occur with powder mixers:

- Improper mixing: This can be caused by a number of factors, such as incorrect mixer selection, improper mixing procedure, or worn-out equipment.

- Contamination: This can be caused by a number of factors, such as improper cleaning, foreign objects in the powder, or leaks in the mixer.

- Overheating: This can be caused by a number of factors, such as excessive mixing time, high mixing speed, or worn-out bearings.

- Mechanical failure: This can be caused by a number of factors, such as worn-out gears, bearings, or seals.

- Electrical failure: This can be caused by a number of factors, such as loose connections, faulty wiring, or damaged components.

5. How do you troubleshoot a powder mixer?

To troubleshoot a powder mixer, you should follow these steps:

- Identify the problem.

- Determine the cause of the problem.

- Take corrective action.

- Verify that the problem has been solved.

6. What are the safety precautions that should be taken when operating a powder mixer?

The following are some of the safety precautions that should be taken when operating a powder mixer:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a dust mask.

- Make sure that the mixer is properly grounded.

- Do not operate the mixer if it is damaged or not working properly.

- Keep the work area clean and free of debris.

- Be aware of the hazards of the powder that you are mixing.

7. What is the difference between a batch mixer and a continuous mixer?

A batch mixer is a mixer that mixes a batch of powder at a time. A continuous mixer is a mixer that continuously mixes powder. Batch mixers are typically used for small batches of powder, while continuous mixers are typically used for large batches of powder.

8. What are the advantages and disadvantages of using a vacuum powder mixer?

Advantages of using a vacuum powder mixer:

- Reduced dust generation

- Improved mixing quality

- Safer operation

Disadvantages of using a vacuum powder mixer:

- Higher cost

- More complex operation

- Longer mixing times

9. What is the role of a dispersion impeller in a powder mixer?

A dispersion impeller is a type of impeller that is used to break up agglomerates and disperse particles in a powder mixer. Dispersion impellers are typically used in high-shear mixers, which are designed to mix powders that are difficult to mix.

10. What are the different types of seals that can be used in a powder mixer?

The following are the different types of seals that can be used in a powder mixer:

- Mechanical seals

- Lip seals

- O-rings

- Gaskets

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Powder Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Powder Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Powder Mixer is responsible for operating and maintaining powder mixing equipment to produce blended powders that meet the specified requirements. Their key responsibilities include:

1. Equipment Operation and Maintenance

Operate powder mixing equipment, such as V-blenders, ribbon blenders, and tumble blenders.

- Monitor equipment performance and adjust parameters as needed.

- Perform routine maintenance and cleaning of equipment.

2. Powder Blending

Prepare and blend powders according to specified formulations.

- Determine the appropriate blending method and equipment based on powder properties.

- Weigh and measure powders accurately.

- Monitor blending process and ensure proper mixing.

3. Quality Control

Perform quality control tests on blended powders.

- Conduct visual inspections and homogeneity tests.

- Analyze samples to verify blend uniformity and meet specifications.

- Document test results and maintain quality records.

4. Safety and Compliance

Follow safety procedures and maintain a clean and organized work environment.

- Wear appropriate personal protective equipment.

- Comply with regulatory requirements and industry standards.

- Report any accidents or incidents promptly.

Interview Tips

To ace your interview for a Powder Mixer position, consider the following tips and tricks:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and industry. Research the specific Powder Mixer position and its responsibilities.

- This knowledge will help you demonstrate your interest and understanding of the role.

2. Highlight Your Experience and Skills

Emphasize your relevant experience in operating powder mixing equipment and performing quality control tests. If you have prior experience in the pharmaceutical or food industry, mention it.

- Use specific examples to demonstrate your skills and capabilities.

3. Show Your Attention to Detail

Powder mixing requires precision and attention to detail. Highlight your ability to follow instructions accurately, weigh and measure ingredients precisely, and maintain a clean and organized work environment.

- Share examples that demonstrate your commitment to quality and accuracy.

4. Prepare for Technical Questions

The interviewer may ask technical questions to assess your understanding of powder mixing principles and equipment. Review these topics and prepare answers that demonstrate your knowledge.

- Be prepared to explain different types of powder mixers and their applications.

5. Be Enthusiastic and Professional

Show your enthusiasm for the role and your desire to contribute to the company. Maintain a professional demeanor throughout the interview and dress appropriately.

- Your positive attitude and willingness to learn will make a lasting impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Powder Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!