Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Powder Nipper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

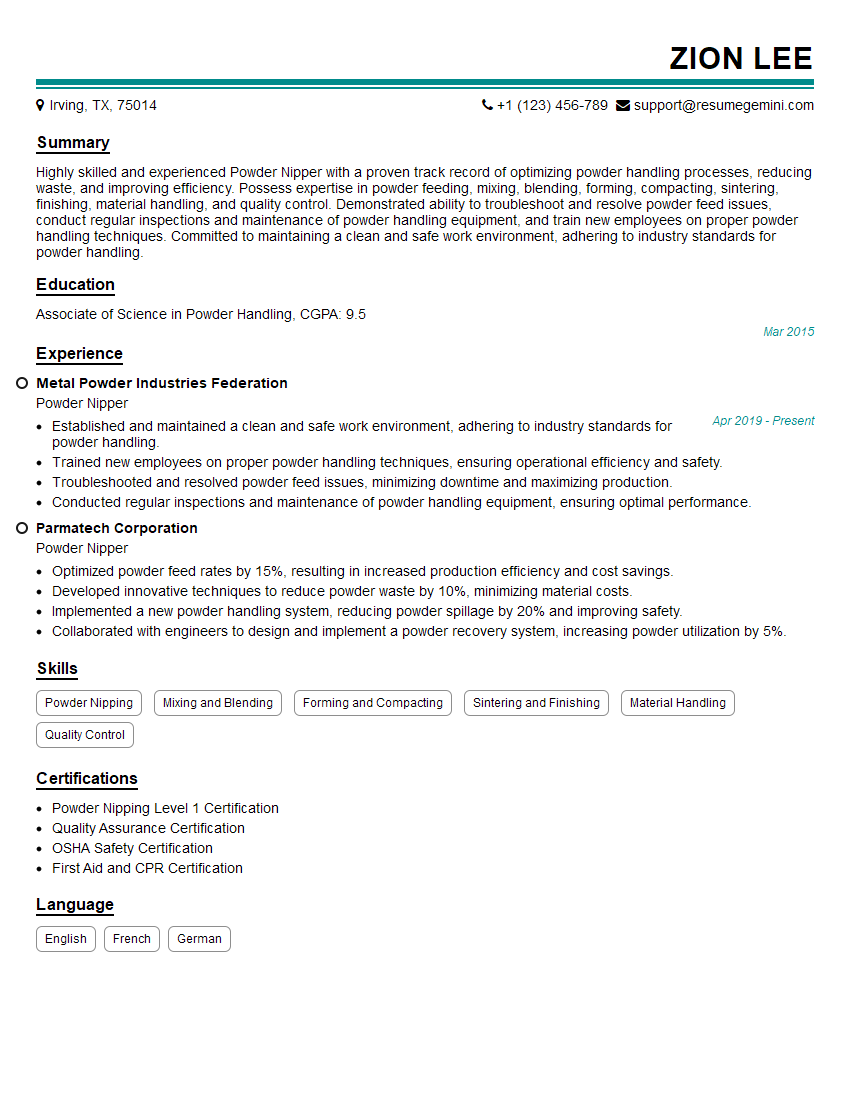

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Powder Nipper

1. Describe the process of powder metallurgy, including the different stages involved.

Powder metallurgy is a metalworking process that involves the production of metal powders, compaction of the powders into a desired shape, and sintering the compacted powder to produce a solid component.

- Powder Production: Powders are produced by various methods such as atomization, reduction, and mechanical alloying.

- Compaction: The powders are compacted into a mold using techniques like cold pressing, hot pressing, or isostatic pressing.

- Sintering: The compacted powder is heated in a controlled atmosphere to strengthen the bonds between the particles and produce a solid component.

2. What are the advantages and disadvantages of powder metallurgy?

Advantages

- Complex shapes can be produced with high precision.

- Allows for the use of a wide range of materials, including difficult-to-machine alloys.

- Reduced material waste and energy consumption compared to traditional machining.

- Enhanced material properties, such as porosity control and wear resistance, can be achieved.

Disadvantages

- Higher tooling costs compared to traditional machining.

- Limited part size and production volume due to press limitations.

- Sintering parameters need to be carefully controlled to avoid defects.

3. Explain the different types of powder metallurgy presses and their applications.

Powder metallurgy presses are classified based on the applied pressure and temperature:

- Cold Pressing: Performed at room temperature, suitable for lower pressures and simple shapes.

- Hot Pressing: Pressing is done while the powder is heated, resulting in higher densities and strengths.

- Isostatic Pressing: Pressure is applied uniformly from all directions, allowing for complex shapes and high densities.

4. Discuss the factors affecting the sintering process in powder metallurgy.

- Temperature: Determines the degree of bonding and densification.

- Time: Allows for sufficient diffusion and grain growth.

- Atmosphere: Controlled to prevent oxidation or other unwanted reactions.

- Particle Size: Affects the sintering rate and final microstructure.

- Pressure: Applied during sintering can enhance densification.

5. What are the post-sintering processes used in powder metallurgy and their purposes?

- Annealing: Improves ductility and toughness.

- Heat Treatment: Alters the material properties, such as hardness and strength.

- Machining: Finalizes the shape and dimensions.

- Coating: Protects against corrosion or enhances wear resistance.

6. Describe the different types of powder metallurgy materials and their applications.

Powder metallurgy materials are classified based on their composition:

- Iron-Based: Automotive parts, gears, cutting tools

- Copper-Based: Electrical contacts, bearings

- Nickel-Based: Aerospace components, corrosion-resistant parts

- Aluminum-Based: Lightweight automotive parts, heat exchangers

- Cemented Carbides: Cutting tools, drill bits

7. Explain the role of particle size and shape in powder metallurgy.

- Particle Size: Smaller particles result in higher surface area and enhanced bonding.

- Particle Shape: Spherical particles provide better flowability and packing, while irregular particles can create interlocking.

8. Discuss the quality control measures used in powder metallurgy production.

- Powder Characterization: Particle size, shape, and composition analysis.

- Compaction Control: Monitoring pressure, temperature, and dwell time.

- Sintering Control: Temperature, atmosphere, and time monitoring.

- Post-Processing Inspection: Dimensional accuracy, surface quality, and material properties testing.

9. What are the current trends and advancements in powder metallurgy?

- Additive Manufacturing: Integrating powder metallurgy with 3D printing for complex shape production.

- Nano-Powder Technology: Utilizing nanoparticles for enhanced performance and new materials.

- Advanced Sintering Techniques: Explorations into microwave, spark plasma, and laser sintering.

- Materials Innovation: Development of new alloys and composites with tailored properties.

10. What is your experience with powder metallurgy equipment and processes?

In my previous role at [Company Name], I was responsible for operating powder metallurgy presses, sintering furnaces, and quality control equipment. I have hands-on experience in powder handling, compaction, sintering, and post-processing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Powder Nipper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Powder Nipper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Powder Nippers are responsible for operating and monitoring equipment that compresses and shapes powders into desired forms. They work in manufacturing facilities that produce a variety of products, including pharmaceuticals, ceramics, and electronics. Key job responsibilities of a Powder Nipper include:

1. Compressing Powders

Powder Nippers operate machines that compress powders into dies or molds to create the desired shape.

- Set up and calibrate compression machines.

- Load powders into dies or molds.

- Operate machines to compress powders.

2. Forming Products

After powders are compressed, Powder Nippers form them into finished products by using a variety of techniques.

- Ejecting products from dies or molds.

- Trimming and finishing products.

- Inspecting products for defects.

3. Maintaining Equipment

Powder Nippers are responsible for maintaining the equipment they use on a regular basis.

- Cleaning and lubricating machines.

- Performing minor repairs.

- Reporting any major problems to supervisors.

4. Quality Control

Powder Nippers are responsible for ensuring that the products they produce meet quality standards.

- Inspecting products for defects.

- Testing products to ensure they meet specifications.

- Maintaining records of quality control tests.

Interview Tips

To ace an interview for a Powder Nipper position, it is important to:

1. Research the Company and the Position

Learn as much as you can about the company and the specific position you are applying for. This will help you to understand the company’s culture, values, and goals, and to tailor your answers to the interviewer’s questions.

- Visit the company’s website.

- Read articles about the company in industry publications.

- Talk to people who work or have worked for the company.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you to feel more confident and prepared during the interview.

- Write down your answers to common interview questions.

- Practice saying your answers aloud.

- Have a friend or family member ask you interview questions and give you feedback.

3. Dress Professionally

First impressions matter. Dress professionally for your interview to show the interviewer that you are serious about the position.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Wear comfortable shoes that you can walk in easily.

4. Be Punctual

Punctuality is important for any job interview. Arrive on time for your interview to show the interviewer that you are respectful of their time.

- Leave early for your interview so that you have plenty of time to get there.

- If you are running late, call the interviewer to let them know.

- Be prepared to wait a few minutes if the interviewer is running behind schedule.

Next Step:

Now that you’re armed with the knowledge of Powder Nipper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Powder Nipper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini