Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Powdered Sugar Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

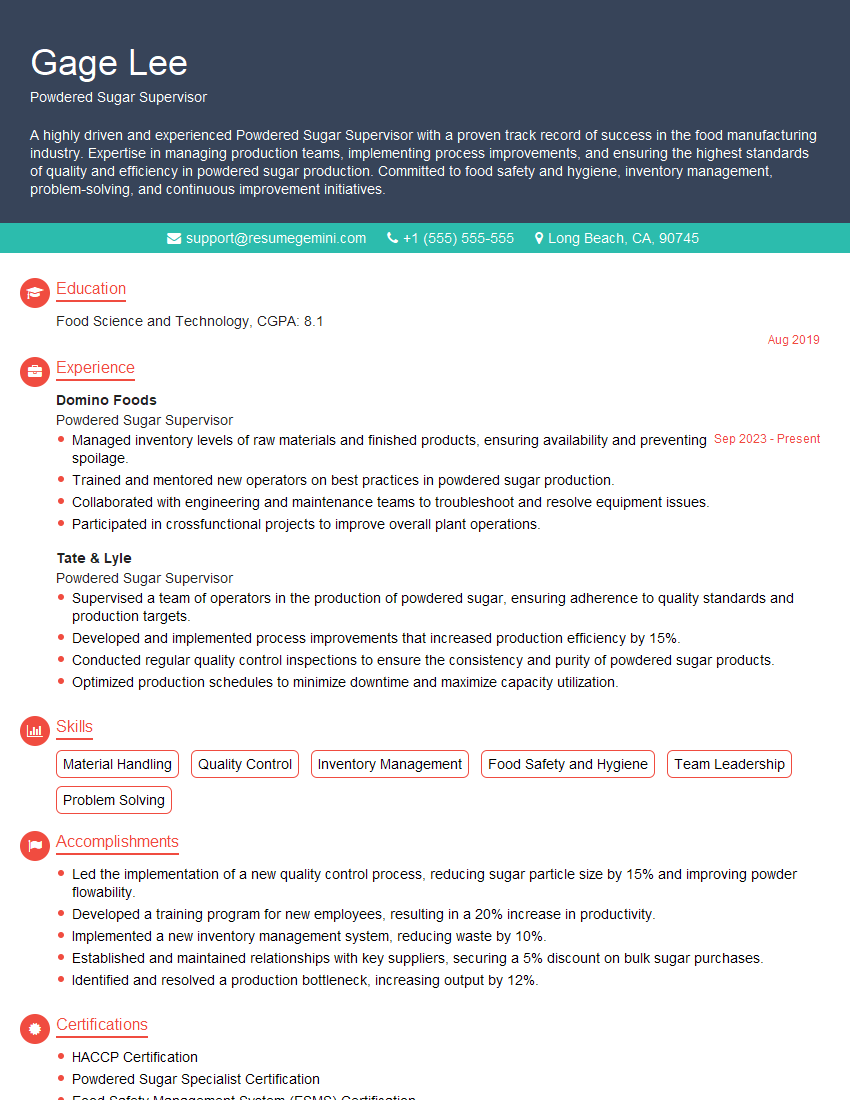

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Powdered Sugar Supervisor

1. Can you explain the key quality parameters and specifications for powdered sugar?

- Particle size distribution and uniformity

- Moisture content and moisture absorption

- Bulk density and flowability

- Chemical composition and purity

- Microbiological safety and shelf life

2. Describe the production process of powdered sugar, including the grinding, sieving, and packaging steps.

Grinding

- Sugar crystals are crushed and ground into finer particles using specialized mills

- Particle size is controlled through adjustments to mill settings and grinding time

Sieving

- Ground sugar is passed through sieves or sifters to separate particles of desired size

- Sieve mesh sizes are selected based on the target particle size distribution

Packaging

- Powdered sugar is packaged in appropriate bags or containers to maintain quality

- Packaging materials are chosen to prevent moisture absorption and contamination

3. How do you ensure that the powdered sugar meets customer specifications and quality standards?

- Regular testing and monitoring of key quality parameters

- Implementation of quality control systems, such as ISO or HACCP

- Calibration and maintenance of equipment to ensure accurate and consistent production

- Training and supervision of staff to ensure adherence to quality standards

- Customer feedback and product audits to identify and address quality issues

4. How do you manage the packaging and storage of powdered sugar to prevent spoilage and maintain quality?

- Use of moisture-proof packaging materials to prevent absorption and caking

- Proper storage conditions, such as dry, cool, and dark areas

- Regular rotation of inventory to prevent long-term storage and degradation

- Monitoring of storage conditions and product quality to detect and address potential issues

5. What are the common issues that can occur during the production of powdered sugar, and how do you troubleshoot and resolve them?

- Issues with particle size or consistency: Adjust mill settings, sieving procedures

- Moisture absorption and caking: Optimize packaging, storage conditions, and moisture control measures

- Contamination or foreign objects: Implement strict hygiene practices, inspect equipment regularly

- Quality deviations: Conduct thorough testing, identify root causes, and implement corrective actions

6. How do you maintain and calibrate the equipment used in the production of powdered sugar, including grinders, sieves, and packaging machines?

- Regular maintenance and inspections to ensure optimal performance

- Calibration of equipment using certified standards to ensure accuracy and precision

- Documentation of maintenance and calibration procedures for traceability and compliance

- Training of staff on proper maintenance and calibration techniques

7. What are the safety and hygiene regulations that must be followed in the production of powdered sugar, and how do you ensure compliance?

- Adherence to food safety and hygiene standards, such as HACCP or GMP

- Use of appropriate personal protective equipment (PPE) by staff

- Regular cleaning and sanitation of equipment and work areas

- Training and supervision of staff on safety and hygiene practices

- Periodic inspections and audits to ensure compliance

8. What is the impact of particle size on the properties and applications of powdered sugar?

- Smaller particle size results in improved solubility and dispersion

- Larger particle size affects texture and sweetness perception

- Particle size distribution influences flowability and caking tendency

- Applications vary depending on particle size, such as confectionery, baking, and food decoration

9. How do you optimize the production process of powdered sugar to increase efficiency and minimize costs?

- Process optimization through data analysis and process control

- Automation and mechanization of production steps where feasible

- Supplier management to ensure quality and cost-effective raw materials

- Minimization of waste and by-products through efficient use of resources

- Lean manufacturing principles to reduce inefficiencies

10. What are the emerging trends and innovations in the production and application of powdered sugar?

- Development of new technologies for grinding and sieving to achieve finer particle sizes

- Exploration of new sources of sugar, such as alternative sweeteners

- Use of nanotechnology to enhance the functionality and properties of powdered sugar

- Innovative applications in food and beverage products, including novel textures and flavor profiles

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Powdered Sugar Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Powdered Sugar Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Powdered Sugar Supervisor, you will be responsible for the overall operation of the powdered sugar production process. This includes managing production schedules, ensuring quality control, and maintaining a safe and efficient work environment. Some of your key job responsibilities include:

1. Production Management

You will be responsible for planning and scheduling powdered sugar production to meet customer demand. This includes coordinating with the production team to ensure that all necessary resources are available and that production runs smoothly.

2. Quality Control

You will be responsible for ensuring that all powdered sugar produced meets the company’s quality standards. This includes conducting quality checks throughout the production process and taking corrective action when necessary.

3. Safety and Compliance

You will be responsible for maintaining a safe and compliant work environment. This includes ensuring that all employees are trained on safety procedures and that all equipment is properly maintained.

4. Inventory Management

You will be responsible for managing the inventory of powdered sugar and other raw materials. This includes tracking inventory levels, placing orders, and ensuring that there is always enough inventory on hand to meet production needs.

Interview Tips

To help you ace your Powdered Sugar Supervisor interview, here are some tips:

1. Research the Company

Before your interview, take some time to research the company and its powdered sugar products. This will give you a better understanding of the company’s culture and what they are looking for in a Powdered Sugar Supervisor.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions you may be asked include:

- Tell me about your experience in the powdered sugar industry.

- What are your strengths and weaknesses as a supervisor?

- How do you ensure that powdered sugar meets quality standards?

- What are your goals for this position?

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt or blouse. You should also make sure your shoes are clean and your hair is neat.

4. Be Enthusiastic and Positive

Hiring managers want to see that you are enthusiastic about the position and that you are a positive person. Be sure to smile, make eye contact, and speak clearly and confidently. You should also be prepared to talk about your passion for the powdered sugar industry.

5. Ask Questions

At the end of your interview, be sure to ask the hiring manager any questions you have about the position or the company. This shows that you are interested in the job and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Powdered Sugar Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!