Are you gearing up for an interview for a Powderer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Powderer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

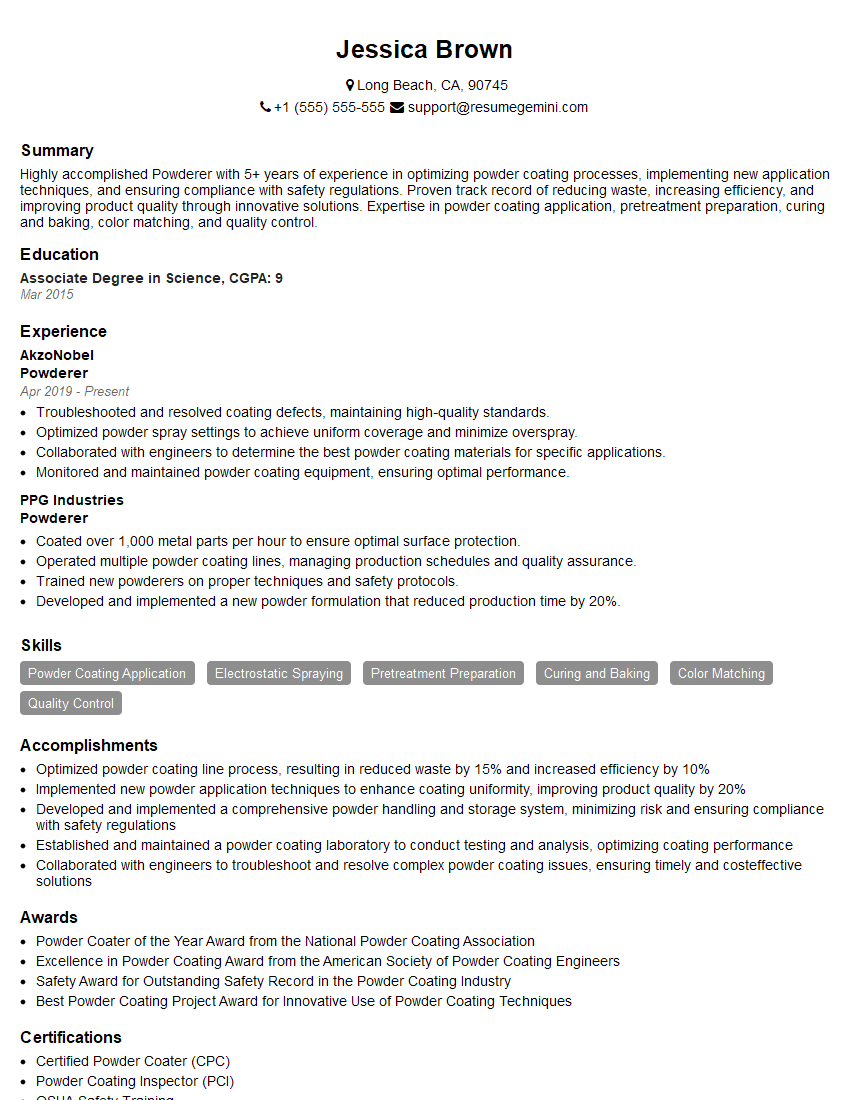

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Powderer

1. Can you describe the processes involved in powder coating?

- Surface preparation: Cleaning and preparing the metal surface to remove any contaminants or impurities.

- Application: Electrostatically spraying the powdered coating onto the surface to create a uniform layer.

- Curing: Heating the coated surface in an oven to melt and fuse the powder particles, creating a durable finish.

2. What are the different types of powder coatings available?

Thermoset powders

- Epoxy: Excellent chemical and corrosion resistance.

- Polyester: Good UV resistance and durability.

Thermoplastic powders

- Nylon: High toughness and flexibility.

- Polyurethane: Excellent abrasion resistance.

3. What are the advantages of powder coating over other finishing methods?

- Durable and long-lasting finish

- Excellent corrosion and chemical resistance

- Wide range of colors and textures available

- Environmentally friendly with minimal VOC emissions

- Cost-effective and efficient process

4. What are the factors that affect the quality of a powder coated finish?

- Surface preparation: Thorough cleaning and removal of contaminants

- Application: Uniform and proper thickness of the powder layer

- Curing: Accurate temperature and time control for proper fusion

- Powder quality: Consistency and compatibility with the substrate

- Environmental conditions: Temperature, humidity, and airflow

5. How do you troubleshoot common problems with powder coating?

- Orange peel: Adjust spraying technique or cure temperature.

- Pinholing: Improve surface preparation or increase powder thickness.

- Fisheyes: Remove contaminants from the surface or spray in a different environment.

- Poor adhesion: Ensure proper surface preparation and optimal cure conditions.

- Color variation: Check powder consistency, application thickness, and cure parameters.

6. What are the safety precautions to consider when powder coating?

- Wear appropriate protective gear (respirator, gloves, eye protection).

- Ventilate the workspace to prevent inhalation of powder particles.

- Properly ground and bond the equipment to prevent electrostatic discharge.

- Handle and dispose of powder waste according to safety guidelines.

- Follow manufacturer’s instructions for proper storage and handling of powders.

7. How do you stay updated with the latest advancements in powder coating technology?

- Attend industry conferences and seminars.

- Read technical journals and articles.

- Consult with manufacturers and suppliers.

- Explore online resources and research.

- Participate in professional organizations and forums.

8. What is your experience with different powder coating equipment?

- Spray guns: Conventional, electrostatic, HVLP.

- Ovens: Batch, conveyor, infrared.

- Conveying and recovery systems.

- Color matching and testing equipment.

- Surface preparation equipment (blasters, degreasers, etc.).

9. How do you ensure the quality of powder coated products?

- Establish clear quality standards.

- Implement rigorous inspection procedures.

- Monitor and control process parameters.

- Use certified materials and equipment.

- Train and certify operators.

10. Can you describe a challenging powder coating project you have worked on?

Explain the specific challenges encountered, the solutions implemented, and the successful outcome achieved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Powderer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Powderer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Powderer is responsible for applying powder to a variety of surfaces to create a smooth, even finish. They may work in a variety of settings, such as a manufacturing plant, a construction site, or a painting studio.

1. Preparing Surfaces

Powderers typically begin by preparing the surface to be powdered. This may involve cleaning the surface, sanding it, or applying a primer.

- Clean surfaces using appropriate cleaning agents and techniques.

- Sand surfaces to remove imperfections and create a smooth base.

- Apply primers to surfaces to improve adhesion and prevent corrosion.

2. Mixing and Applying Powder

Once the surface is prepared, the powderer will mix the powder according to the manufacturer’s instructions. They will then apply the powder to the surface using a variety of methods, such as a spray gun, a brush, or a dipping tank.

- Mix powder according to manufacturer specifications.

- Apply powder to surfaces using spray guns, brushes, or dipping tanks.

- Control powder flow and thickness to achieve desired results.

3. Finishing and Inspection

After the powder has been applied, the powderer will finish the surface. This may involve curing the powder, buffing it, or painting it. They will also inspect the surface to ensure that it meets the required specifications.

- Cure powder at specified temperatures and durations.

- Buff or polish surfaces to enhance appearance and durability.

- Inspect finished surfaces for defects and ensure compliance with quality standards.

4. Maintenance and Safety

Powderers are responsible for maintaining their equipment and work area. They must also follow all safety procedures, such as wearing respirators and protective clothing.

- Maintain powder application equipment, including spray guns and dipping tanks.

- Clean and organize work area to ensure a safe and efficient environment.

- Follow safety protocols, such as wearing respirators and protective clothing.

Interview Tips

Preparing for a Powderer interview can be a daunting task, but following these tips can help you increase your chances of success.

1. Research the Job and Company

Before your interview, take some time to research the job and the company. This will help you understand the company’s culture and the specific requirements of the position.

- Visit the company’s website to learn about their mission, values, and products/services.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Once you have a good understanding of the job and the company, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering questions about your availability, salary expectations, and career goals.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job and the company culture.

- Choose clothing that is comfortable and allows you to move freely.

- Avoid wearing clothing that is too revealing or too casual.

4. Be Punctual

Punctuality is a sign of respect, so it is important to arrive on time for your interview. If you are running late, be sure to call the interviewer to let them know.

- Plan your route to the interview location in advance.

- Leave early to give yourself plenty of time to get there.

5. Be Confident

Confidence is key in any interview, so it is important to project a positive and confident attitude. This will help you make a good impression on the interviewer and show them that you are capable of handling the job.

- Make eye contact with the interviewer and speak clearly and confidently.

- Use positive body language, such as smiling and sitting up straight.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Powderer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Powderer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.