Feeling lost in a sea of interview questions? Landed that dream interview for Power Barker Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Power Barker Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

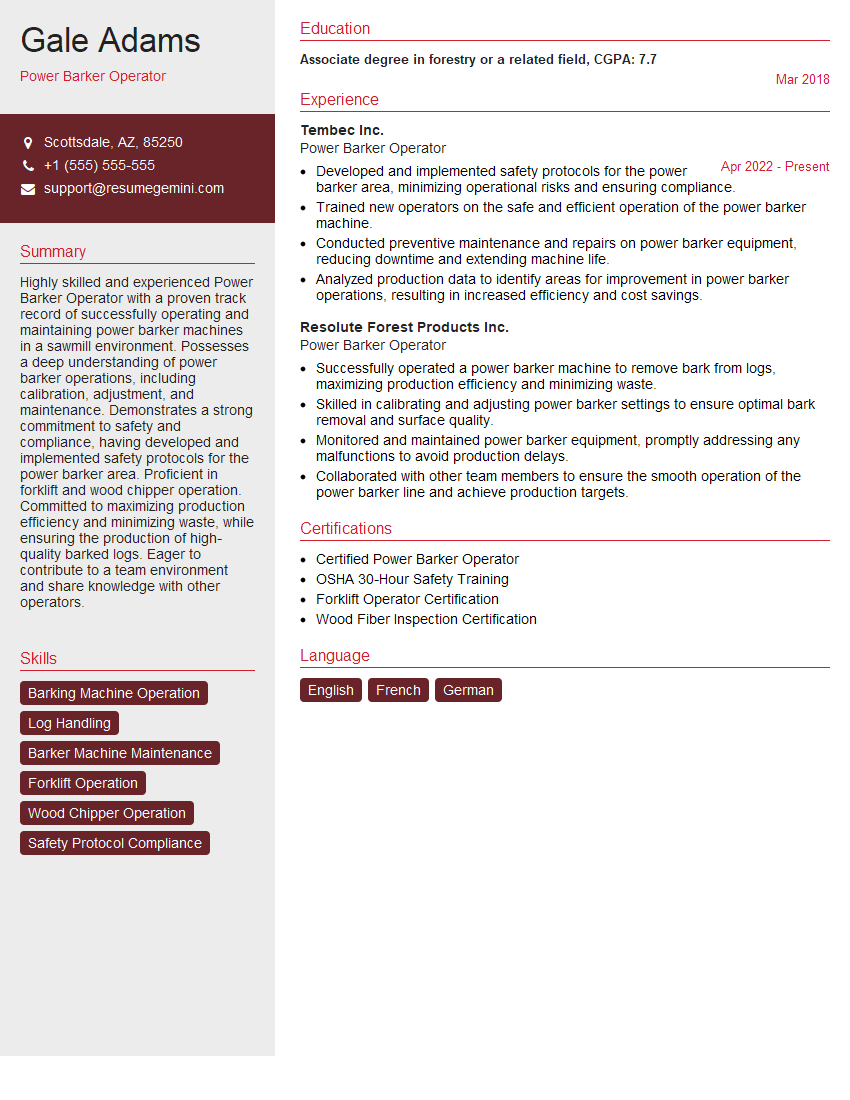

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Barker Operator

1. How would you approach a situation where the barker is producing uneven bark?

- Inspect the barker’s settings and make necessary adjustments, such as the gap between the anvil and the flail.

- Check the condition of the flail and anvil, replacing or sharpening them if needed.

- Examine the logs being fed into the barker and ensure they are of appropriate size and free from knots or other imperfections.

2. Describe the safety precautions you take when operating a power barker.

Personal Protective Equipment

- Wear earplugs or earmuffs to protect against excessive noise.

- Use safety glasses or a face shield to prevent flying bark particles from injuring eyes.

- Wear gloves to protect hands from sharp bark and splinters.

Machine Operation

- Ensure the barker is properly grounded and all guards are in place.

- Never operate the barker with loose clothing or jewelry that could get caught in the machinery.

- Keep a safe distance from the barker’s moving parts and avoid touching them while the machine is running.

3. Explain the process of adjusting the flail gap on a power barker.

- Turn off the barker and disconnect it from the power source.

- Loosen the bolts or nuts that secure the anvil to the frame.

- Adjust the anvil to the desired gap using a measuring tool, such as a feeler gauge or caliper.

- Tighten the bolts or nuts to secure the anvil in the adjusted position.

4. How do you maintain the efficiency of a power barker?

- Regularly inspect and sharpen the flail and anvil, ensuring they remain sharp for optimal bark removal.

- Lubricate the barker’s moving parts according to the manufacturer’s instructions to reduce friction and wear.

- Clean the barker thoroughly after use to remove any bark residue or debris that could affect its performance.

5. Describe the different types of logs suitable for processing with a power barker.

- Softwood logs: Pine, fir, spruce, and hemlock are examples of softwood logs that are commonly processed in barkers.

- Hardwood logs: Oak, maple, birch, and ash are examples of hardwood logs that can also be processed in barkers, but they may require a more aggressive flail setting.

- Diameter and length: The size and shape of the logs should be compatible with the capacity of the barker to ensure efficient processing.

6. What are the challenges you have faced in operating a power barker and how did you overcome them?

- Uneven bark removal: Adjusting the flail gap and inspecting the flail and anvil condition resolved this issue.

- Excessive noise: Wearing earplugs or earmuffs effectively reduced the noise levels.

- Log jams: Ensuring logs are fed into the barker at a steady and controlled rate prevented log jams.

7. How would you troubleshoot a power barker that is not removing bark effectively?

- Check the flail and anvil for damage or dullness, and sharpen or replace them if necessary.

- Inspect the flail gap and adjust it to ensure it is within the recommended range.

- Examine the logs being fed into the barker and make sure they are suitable for processing.

8. Describe the proper procedures for starting and stopping a power barker safely.

Starting Procedure

- Ensure the area around the barker is clear of obstructions.

- Connect the barker to a power source.

- Turn on the barker and allow it to reach full speed before feeding logs.

Stopping Procedure

- Stop feeding logs into the barker.

- Turn off the barker and disconnect it from the power source.

- Wait for all moving parts to come to a complete stop before approaching the barker.

9. How do you ensure the bark removed by the power barker meets quality standards?

- Inspect the bark for thickness, consistency, and absence of wood fragments or other contaminants.

- Use a bark gauge or caliper to measure the bark thickness and ensure it meets specifications.

- Regularly calibrate the barker’s settings to maintain consistent bark quality.

10. Describe the importance of preventive maintenance for power barkers.

- Reduces the risk of unexpected breakdowns and production interruptions.

- Extends the life of the barker by preventing premature wear and tear.

- Enhances safety by ensuring the barker is operating at its optimal performance.

- Optimizes bark quality by maintaining proper settings and ensuring the flail and anvil are in good condition.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Barker Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Barker Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Power Barker Operators possess an intricate set of abilities, centered around ensuring the efficient operation of power barkers within a sawmill setting. Their responsibilities encompass a wide range of tasks, including:

1. Machine Operation

Skilled Power Barker Operators effortlessly manage the intricate operations of power barking machines. They meticulously control feed rates, ensuring optimal bark removal while safeguarding log quality. Their keen attention to detail prevents damage to logs, preserving their value and minimizing waste.

- Feed logs into the power barker with precision and care.

- Monitor and adjust machine settings to maximize bark removal efficiency.

2. Quality Control

In their relentless pursuit of excellence, Power Barker Operators serve as vigilant guardians of product quality. They meticulously inspect logs before and after processing, identifying any defects that could compromise the final product. Their discerning eyes detect blemishes, knots, and other imperfections, ensuring that only flawless logs progress to subsequent stages of production.

- Inspect logs for defects, knots, and other quality concerns.

- Remove defective logs from the production line to maintain quality standards.

3. Maintenance and Safety

Power Barker Operators embrace the mantle of safety and maintenance with unwavering dedication. They vigilantly inspect and maintain their equipment, memastikan its optimal performance and the safety of the work environment. By proactively addressing potential issues, they minimize downtime and prevent accidents, fostering a culture of safety and productivity.

- Perform routine maintenance tasks on power barkers.

- Adhere to established safety protocols and procedures.

4. Log Handling

Power Barker Operators are veritable maestros of log handling, deftly maneuvering these heavy logs with precision and efficiency. Their ability to stack, unstack, and transport logs ensures a seamless flow of materials throughout the production process. They maintain a keen awareness of their surroundings, ensuring the safety of themselves and others.

- Stack and unstack logs using proper techniques.

- Transport logs to designated areas using forklifts or other equipment.

Interview Tips

Preparing for a Power Barker Operator interview requires a strategic approach. By following these tips, candidates can enhance their chances of success:

1. Research the Company and Position

A thorough understanding of the company’s culture, values, and the specific requirements of the Power Barker Operator role is paramount. Visit the company’s website, read industry news, and connect with current or former employees on LinkedIn to gain valuable insights.

- Tailor your responses to the specific job description.

- Demonstrate your knowledge of the company’s products, services, and industry standing.

2. Practice Your Answers

Anticipate common interview questions and rehearse your responses. Focus on highlighting your skills, experience, and enthusiasm for the role. Use the STAR method to structure your answers, providing specific examples of your accomplishments.

- Prepare for questions about your experience in operating power barking machines.

- Rehearse your responses to questions about quality control and safety procedures.

3. Showcase Your Safety Awareness

Safety is a top priority in any industrial setting. Emphasize your commitment to adhering to established safety protocols and procedures. Share examples of how you have proactively identified and mitigated potential hazards in previous roles.

- Highlight your understanding of lockout/tagout procedures.

- Demonstrate your knowledge of proper personal protective equipment (PPE) usage.

4. Display Your Physical Fitness

Power Barker Operators perform physically demanding tasks. During the interview, be prepared to discuss your physical fitness and ability to work in a fast-paced, physically demanding environment.

- Emphasize your strength, endurance, and agility.

- Highlight any experience you have in lifting heavy objects or working in physically demanding roles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Power Barker Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.