Are you gearing up for a career in Power Brake Rebuilder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Power Brake Rebuilder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

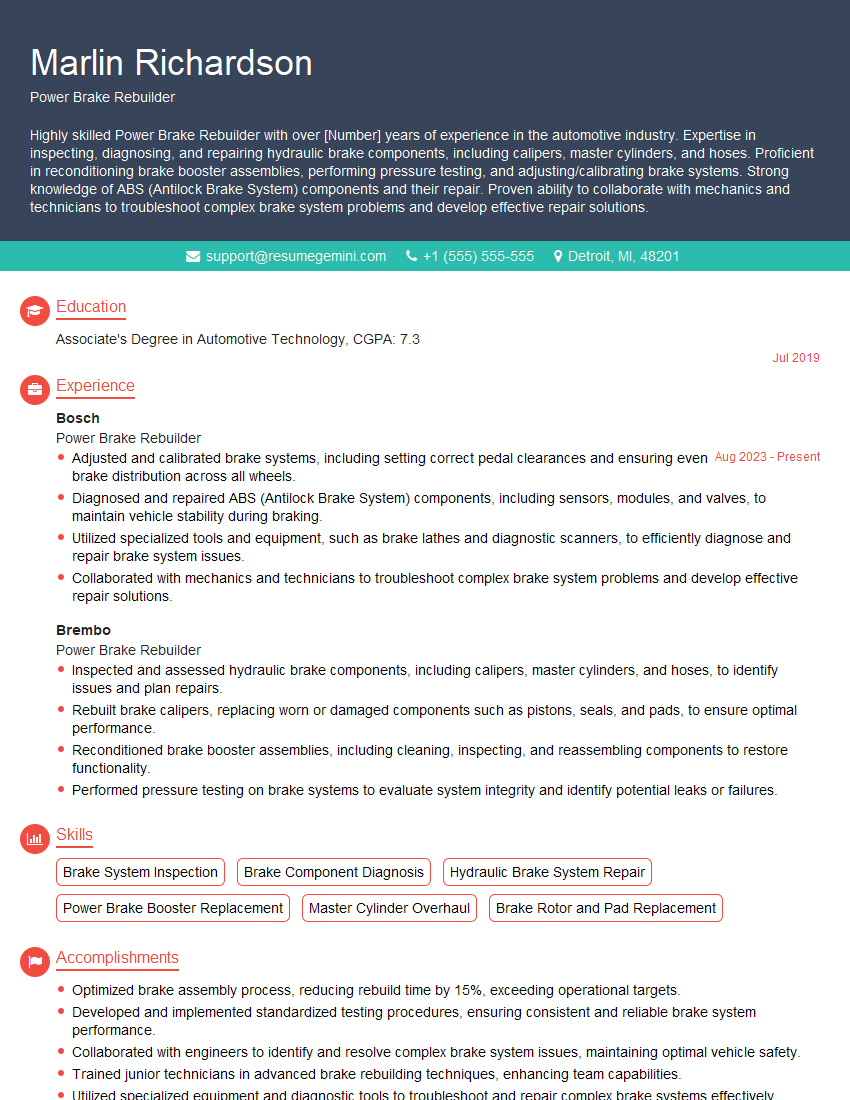

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Brake Rebuilder

1. How do you determine if a master cylinder is faulty?

To determine if a master cylinder is faulty, I would perform the following checks:

- Visual inspection: Check for any leaks or damage to the master cylinder.

- Fluid level check: Ensure the fluid level is adequate and check for any signs of contamination.

- Pressure test: Use a pressure gauge to measure the pressure generated by the master cylinder. Compare the results to manufacturer specifications.

- Bench bleeding: Remove the master cylinder and connect it to a bleeder screw. Pump the piston to check for any leaks or spongy feel.

2. Describe the process of rebuilding a power brake booster.

Disassembly

- Remove the vacuum hose and mounting bolts.

- Separate the diaphragm housing from the body.

- Inspect the diaphragm, check valve, and seals for damage.

Cleaning and Inspection

- Thoroughly clean all components with brake cleaner.

- Inspect the bore for any scoring or corrosion.

- Check the pushrod for wear or damage.

Reassembly

- Replace any damaged components.

- Lubricate the bore and pushrod.

- Install the diaphragm and check valve.

- Reassemble the booster and test it for proper operation.

3. How do you troubleshoot a brake pedal that feels spongy?

To troubleshoot a brake pedal that feels spongy, I would follow these steps:

- Check the brake fluid level: Verify that the fluid level is adequate and top up if necessary.

- Inspect the brake lines: Look for any leaks or damage to the brake lines.

- Bleed the brakes: Remove any air from the brake system by bleeding the brakes at each wheel.

- Check the master cylinder: Test the master cylinder for proper operation using a pressure gauge.

- Inspect the brake pads: Worn brake pads can contribute to a spongy pedal feel.

4. How do you adjust the rear brakes on a vehicle with drum brakes?

To adjust the rear brakes on a vehicle with drum brakes, I would follow these steps:

- Remove the wheels: Loosen the lug nuts and remove the rear wheels.

- Locate the adjusting star wheel: Remove the access plug on the backing plate to expose the star wheel.

- Adjust the star wheel: Use an adjuster tool to rotate the star wheel while applying pressure to the brake shoes.

- Check the brake pedal: Pump the brake pedal several times to ensure proper adjustment.

- Reinstall the wheels: Tighten the lug nuts and torque them to the manufacturer’s specifications.

5. What are the different types of brake rotors and their advantages and disadvantages?

The different types of brake rotors include:

- Solid rotors:

- Advantages: Cost-effective, easy to maintain

- Disadvantages: Can overheat, not as efficient as ventilated rotors

- Ventilated rotors:

- Advantages: Better heat dissipation, increased braking performance

- Disadvantages: More expensive, more difficult to maintain

- Drilled rotors:

- Advantages: Improved gas release, reduced brake fade

- Disadvantages: Can be noisy, reduced rotor lifespan

- Slotted rotors:

- Advantages: Enhanced water and debris removal, reduced glazing

- Disadvantages: Can be noisy, reduced rotor lifespan

6. How do you diagnose and repair a leaking brake caliper?

To diagnose and repair a leaking brake caliper, I would follow these steps:

- Visual inspection: Check the caliper for any obvious leaks or damage.

- Pressure test: Use a pressure gauge to apply pressure to the brake system and identify the location of the leak.

- Disassembly: Remove the caliper from the vehicle and disassemble it.

- Inspection: Inspect the piston, seals, and other components for damage or wear.

- Repair: Replace any damaged or worn components and reassemble the caliper.

- Lubrication: Lubricate the moving parts of the caliper before reinstalling it.

7. What are the safety precautions that should be taken when working on brake systems?

When working on brake systems, it is crucial to prioritize safety by taking the following precautions:

- Wear appropriate safety gear: Gloves, safety glasses, and protective clothing.

- Use proper tools: Ensure you have the necessary tools and equipment for the job.

- Raise the vehicle safely: Use a sturdy jack and jack stands to safely lift the vehicle.

- Disconnect the battery: Prevent electrical shock by disconnecting the negative battery terminal.

- Release brake fluid pressure: Pump the brake pedal several times to reduce pressure in the system.

8. What are the different types of brake fluids and their applications?

Different types of brake fluids include:

- DOT 3: Standard brake fluid for most passenger vehicles.

- DOT 4: High-performance brake fluid with a higher boiling point.

- DOT 5: Silicone-based brake fluid with excellent heat resistance.

- DOT 5.1: High-performance brake fluid with low viscosity.

9. How do you identify and replace worn brake pads?

I identify and replace worn brake pads by:

- Visual inspection: Check the thickness of the brake pads through the caliper inspection hole or by removing the wheels.

- Listen for squealing noises: Worn brake pads often produce a high-pitched squealing sound when braking.

- Measure pad thickness: Use a caliper or micrometer to measure the remaining brake pad thickness.

- Replacement: Compress the caliper piston using a C-clamp or brake pad spreader, remove the old pads, and install new ones.

10. What are the common causes of ABS brake system failure?

Common causes of ABS brake system failure include:

- Faulty wheel speed sensors: Sensors that monitor wheel speed can fail, leading to incorrect ABS operation.

- Malfunctioning ABS module: The electronic control unit responsible for managing the ABS system can become faulty.

- Damaged wiring: Electrical issues within the ABS system, such as broken wires or loose connections.

- Hydraulic problems: Leaks or blockages in the brake lines or calipers can affect ABS performance.

- Low battery voltage: Insufficient battery voltage can interfere with the ABS system’s electronic components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Brake Rebuilder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Brake Rebuilder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Power Brake Rebuilder, you will play a vital role in the maintenance and repair of brake systems in vehicles. Your primary responsibilities will include:

1. Brake System Inspection and Repair

Thoroughly inspect brake systems for wear, damage, or leaks.

- Disassemble and analyze brake pads, rotors, calipers, and master cylinders.

- Diagnose and repair faulty brake components, including hydraulic and mechanical parts.

2. Parts Replacement and Reconditioning

Replace worn or damaged brake components with new or reconditioned parts.

- Resurface brake rotors to restore proper friction and braking performance.

- Reassemble and adjust brake assemblies to ensure optimal functionality.

3. Quality Assurance and Testing

Perform comprehensive inspections to verify the quality and accuracy of brake repairs.

- Test drive vehicles to evaluate brake performance and ensure safe operation.

- Document and report any issues identified during inspections or testing.

4. Customer Service

Provide exceptional customer service by clearly explaining repairs and answering customer questions.

- Effectively communicate with customers and keep them informed about the progress of their repairs.

- Offer recommendations for preventive maintenance and additional services.

Interview Preparation Tips

To ace the interview for a Power Brake Rebuilder position, follow these tips:

1. Research the Company and Position

Thoroughly research the dealership or repair facility you are applying to, as well as the specific responsibilities of the Power Brake Rebuilder role.

- Visit the company website and social media pages to learn about their culture and values.

- Review the job description carefully and identify the key qualifications and skills they are seeking.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your expertise in brake system repair and maintenance.

- Quantify your experience by providing specific examples of the number of brake repairs you have performed.

- Showcase your proficiency in using specialized tools and equipment for brake servicing.

3. Demonstrate Problem-Solving Abilities

Highlight your problem-solving skills and ability to diagnose and resolve brake issues efficiently.

- Describe a challenging brake repair situation you encountered and how you used your knowledge and troubleshooting skills to find a solution.

- Explain your approach to testing and verifying the effectiveness of brake repairs.

4. Emphasize Safety and Quality

Stress your commitment to safety and the importance of maintaining high-quality standards in brake repairs.

- Explain your adherence to industry best practices and safety protocols.

- Highlight your attention to detail and thorough inspections to ensure the safe and reliable operation of brake systems.

5. Practice and Prepare

Prior to the interview, practice answering common interview questions and prepare thoughtful questions to ask the interviewer.

- Anticipate questions about your experience, skills, and motivation for the role.

- Prepare questions that demonstrate your interest in the company and the position, such as their training programs or opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Power Brake Rebuilder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Power Brake Rebuilder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.