Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Power Hammer Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Power Hammer Operator so you can tailor your answers to impress potential employers.

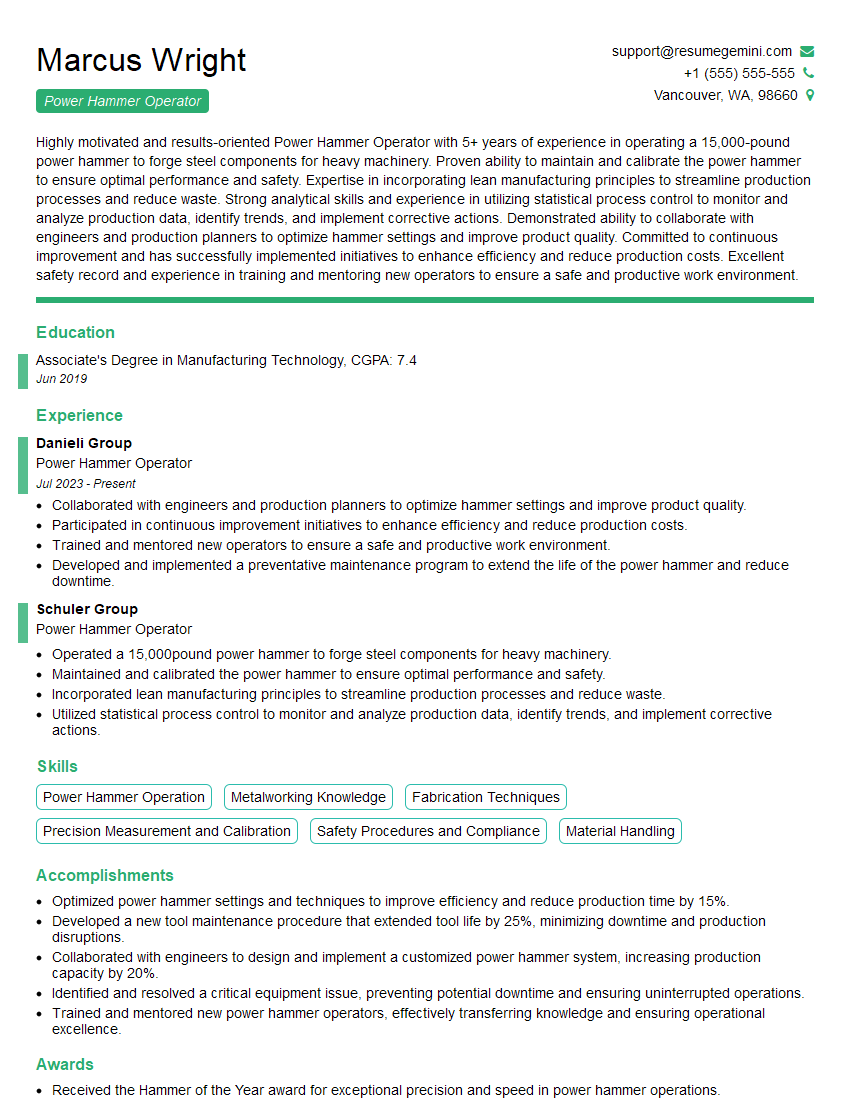

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Hammer Operator

1. What safety precautions do you take when operating a power hammer?

When operating a power hammer, I prioritise safety by adhering to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Ensuring the work area is clear of obstructions and that the machine is properly grounded.

- Inspecting the hammer and dies before each use to ensure they are in good working condition.

- Using the hammer only for its intended purpose and within its specified operating parameters.

- Following established lockout/tagout procedures when servicing or repairing the machine.

2. How do you determine the correct power settings for a given job?

Determining the correct power settings for a power hammer job involves:

- Assessing the material being worked on, its thickness, and hardness.

- Considering the size and shape of the die being used.

- Adjusting the hammer’s speed and force to achieve the desired result without damaging the material or the machine.

- Experimenting with different settings based on experience and knowledge of the machine’s capabilities.

3. What techniques do you use to achieve precise forging with a power hammer?

To achieve precise forging with a power hammer, I employ various techniques, including:

- Using a variety of dies to create different shapes and sizes.

- Controlling the hammer’s speed and force to manipulate the material’s flow.

- Using jigs or fixtures to hold the workpiece in place and ensure accuracy.

- Annealing the material as needed to make it more malleable and easier to shape.

- Paying close attention to the workpiece’s temperature to prevent overheating or cracking.

4. How do you troubleshoot common problems with a power hammer?

When troubleshooting common problems with a power hammer, I follow a systematic approach:

- Identifying the symptoms of the problem and isolating its potential causes.

- Checking the machine’s power supply, electrical connections, and mechanical components.

- Inspecting the dies for wear or damage and replacing them if necessary.

- Adjusting the hammer’s settings or recalibrating its sensors to resolve performance issues.

- Consulting with experienced colleagues or manufacturers’ support teams for more complex troubleshooting.

5. What maintenance procedures are essential for keeping a power hammer in optimal condition?

To maintain a power hammer in optimal condition, I perform regular maintenance procedures, including:

- Cleaning and lubricating all moving parts regularly.

- Checking and tightening bolts and fasteners to prevent loosening and vibrations.

- Inspecting the hammer’s electrical components for damage or loose connections.

- Replacing worn or damaged dies and other components as needed.

- Following the manufacturer’s recommended maintenance schedule for periodic inspections and overhauls.

6. How do you plan and prepare for a forging project using a power hammer?

Planning and preparation for a forging project using a power hammer involve:

- Understanding the project requirements and specifications.

- Selecting the appropriate materials and dies for the job.

- Determining the necessary power settings and forging techniques.

- Preparing the workpiece by cutting, shaping, and heating it as required.

- Ensuring that all safety precautions are in place and PPE is worn.

7. What factors influence the choice of dies for a power hammer forging operation?

The choice of dies for a power hammer forging operation depends on several factors:

- The material being forged and its properties.

- The shape and size of the desired forged part.

- The available power hammer capacity and capabilities.

- The desired surface finish and dimensional accuracy.

- The overall cost and availability of suitable dies.

8. How do you ensure the quality and consistency of forged parts produced using a power hammer?

To ensure the quality and consistency of forged parts produced using a power hammer, I focus on:

- Proper machine setup and calibration.

- Careful selection and maintenance of dies.

- Precise control of forging parameters (temperature, force, etc.).

- Regular inspection and monitoring of forged parts.

- Continuous improvement and refinement of techniques.

9. What are the safety hazards associated with power hammer operation, and how can they be mitigated?

The safety hazards associated with power hammer operation include:

- Pinch points and crushing hazards.

- Flying debris and sparks.

- Electrical hazards.

- Noise and vibration.

- Heat and burns.

To mitigate these hazards, it is crucial to:

- Follow proper operating procedures.

- Wear appropriate PPE.

- Maintain the machine and dies in good condition.

- Use guards and safety devices.

- Receive adequate training and supervision.

10. How do you stay up-to-date with advancements in power hammer technology and forging techniques?

To stay up-to-date with advancements in power hammer technology and forging techniques, I:

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussions.

- Seek training from equipment manufacturers and experts.

- Experiment with new techniques and share knowledge with colleagues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Power Hammer Operators are responsible for operating power hammers to forge and shape metal objects. They must have the physical strength and stamina to operate the machinery and the attention to detail to ensure that the finished products meet specifications.

1. Operating Power Hammers

Power Hammer Operators are responsible for:

- Setting up and operating power hammers

- Adjusting the settings on the hammer to achieve the desired shape and size of the metal object

- Maintaining the power hammer and its tooling

2. Forging and Shaping Metal Objects

Power Hammer Operators use power hammers to forge and shape metal objects such as:

- Tooling, including hammers, dies, and punches

- Automotive parts, such as crankshafts, gears, and brake drums

- Aerospace components, such as wings, fuselages, and engine parts

3. Quality Control

Power Hammer Operators are responsible for:

- Inspecting the finished products to ensure that they meet specifications

- Identifying and correcting any defects

- Maintaining records of the production process

4. Safety

Power Hammer Operators must follow all safety procedures to prevent accidents.

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs

- Keep the work area clean and organized

- Report any unsafe conditions to the supervisor

Interview Tips

To ace an interview for a Power Hammer Operator position, it is important to be prepared. Here are some tips:

1. Research the Company

Before the interview, research the company to learn about its history, products, and culture. This will help you show the interviewer that you are interested in the position and the company.

2. Practice Your Answers

Take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with operating power hammers?

- How do you handle working in a fast-paced environment?

3. Dress Professionally

Dress professionally for the interview. This will show the interviewer that you are serious about the position and that you respect the company.

4. Be Yourself

Be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Now that you’re armed with the knowledge of Power Hammer Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Power Hammer Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini