Feeling lost in a sea of interview questions? Landed that dream interview for Power Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Power Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

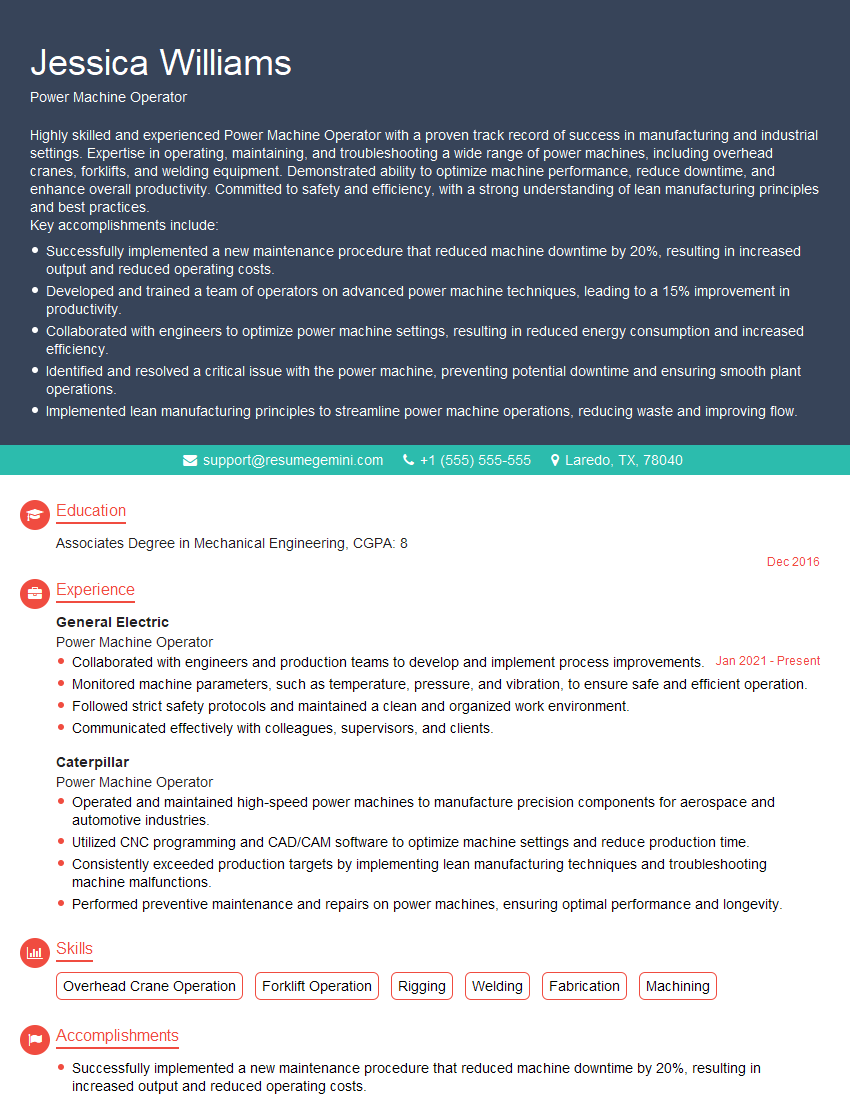

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Machine Operator

1. How would you identify the cause of a power machine breakdown?

To identify the cause of a power machine breakdown, I would follow a systematic troubleshooting process:

- Visual inspection: Check for any obvious signs of damage, such as loose wires, broken belts, or leaking fluids.

- Electrical tests: Use a multimeter to test for continuity, voltage, and current in the electrical system.

- Mechanical tests: Check for worn or damaged bearings, gears, and other mechanical components.

- Software diagnostics: If the machine is controlled by a computer, run diagnostic software to identify any errors or malfunctions.

- Review maintenance records: Check the maintenance records to see if any recent repairs or adjustments may have contributed to the breakdown.

2. Describe the maintenance procedures you would perform on a power machine to ensure its optimal performance

Daily maintenance

- Check fluid levels and top up if necessary

- Inspect belts and hoses for wear and tear

- Clean and lubricate moving parts

- Monitor temperature and vibration levels

Weekly maintenance

- Tighten bolts and nuts

- Inspect electrical connections

- Calibrate sensors

- Update software if necessary

Monthly maintenance

- Perform a thorough inspection of the machine

- Replace filters and fluids

- Lubricate all moving parts

- Calibrate the machine

Annual maintenance

- Overhaul the machine

- Replace worn or damaged parts

- Calibrate the machine to factory specifications

- Update the machine’s software

3. How would you adjust the speed of a power machine to meet different production requirements?

The speed of a power machine can be adjusted in a number of ways, depending on the type of machine.

- Mechanical adjustment: This involves changing the gear ratio or belt drive to alter the speed of the machine.

- Electrical adjustment: This involves changing the frequency or voltage of the power supply to the motor.

- Computer control: This involves using a computer to control the speed of the machine.

When adjusting the speed of a power machine, it is important to consider the following factors:

- The type of material being processed

- The desired production rate

- The safety of the operator

4. How would you ensure that a power machine is operating safely?

To ensure that a power machine is operating safely, I would take the following steps:

- Follow all safety procedures and guidelines

- Inspect the machine before each use

- Wear appropriate safety gear

- Be aware of the potential hazards of the machine

- Never operate the machine while under the influence of alcohol or drugs

- Report any unsafe conditions or practices to your supervisor

5. How would you troubleshoot a power machine that is not starting?

If a power machine is not starting, I would troubleshoot the problem using the following steps:

- Check the power source

- Check the fuses and circuit breakers

- Check the wiring

- Check the motor

- Check the controls

6. How would you align a power machine?

To align a power machine, I would use a precision level and a straightedge.

- Place the level on the machine’s base

- Adjust the machine’s feet until the level is level

- Place the straightedge on the machine’s table

- Adjust the machine’s table until the straightedge is parallel to the base

7. How would you maintain a power machine’s lubrication system?

To maintain a power machine’s lubrication system, I would:

- Check the oil level regularly

- Change the oil and filter according to the manufacturer’s recommendations

- Inspect the oil lines and fittings for leaks

- Lubricate all moving parts according to the manufacturer’s recommendations

8. How would you troubleshoot a power machine that is vibrating excessively?

If a power machine is vibrating excessively, I would troubleshoot the problem using the following steps:

- Check the machine’s foundation

- Check the machine’s bearings

- Check the machine’s alignment

- Check the machine’s balance

- Check the machine’s motor

9. How would you repair a power machine that has a damaged part?

To repair a power machine that has a damaged part, I would:

- Identify the damaged part

- Remove the damaged part

- Replace the damaged part with a new one

- Test the machine to ensure that it is operating properly

10. What are the most common safety hazards associated with operating power machines?

The most common safety hazards associated with operating power machines include:

- Electrical shock

- Mechanical hazards

- Chemical hazards

- Noise

- Vibration

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Power Machine Operators are responsible for operating and maintaining a variety of power machines used in the manufacturing process. Their key responsibilities include:

1. Machine Operation

Operate a variety of power machines, such as drills, grinders, saws, and lathes, to produce parts or products.

- Set up and adjust machines according to specifications.

- Load and unload materials into and out of machines.

- Monitor machines during operation to ensure that they are running properly.

2. Machine Maintenance

Performing routine maintenance on machines, such as cleaning, lubrication, and minor repairs.

- Inspect machines for wear and tear.

- Replace worn or damaged parts.

- Troubleshoot and resolve machine problems.

3. Quality Control

Inspect parts or products produced by machines to ensure that they meet quality standards.

- Use measuring tools to check dimensions and tolerances.

- Identify and correct defects.

4. Safety

Follow safety procedures and wear appropriate protective gear when operating machines.

- Maintain a clean and organized work area.

- Report any unsafe conditions.

Interview Tips

To ace a Power Machine Operator interview, it is essential to highlight your technical skills and experience operating power machines. Here are some tips to help you prepare for the interview:

1. Research the Company and Position

Research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people in your network who work in the industry.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and prepared during the interview.

- Tell me about your experience operating power machines.

- What are your strengths and weaknesses as a Power Machine Operator?

- Why are you interested in this position?

3. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the position. Be specific and provide examples of your work.

- Highlight your experience operating different types of power machines.

- Describe your experience in troubleshooting and resolving machine problems.

- Mention any certifications or training you have received.

4. Be Prepared to Discuss Safety

Safety is a critical aspect of being a Power Machine Operator. Be prepared to discuss your safety practices and how you ensure a safe work environment.

- Describe your experience following safety procedures.

- Explain how you identify and mitigate safety hazards.

- Mention any safety training you have received.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Power Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!