Are you gearing up for a career in Power Plant Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Power Plant Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

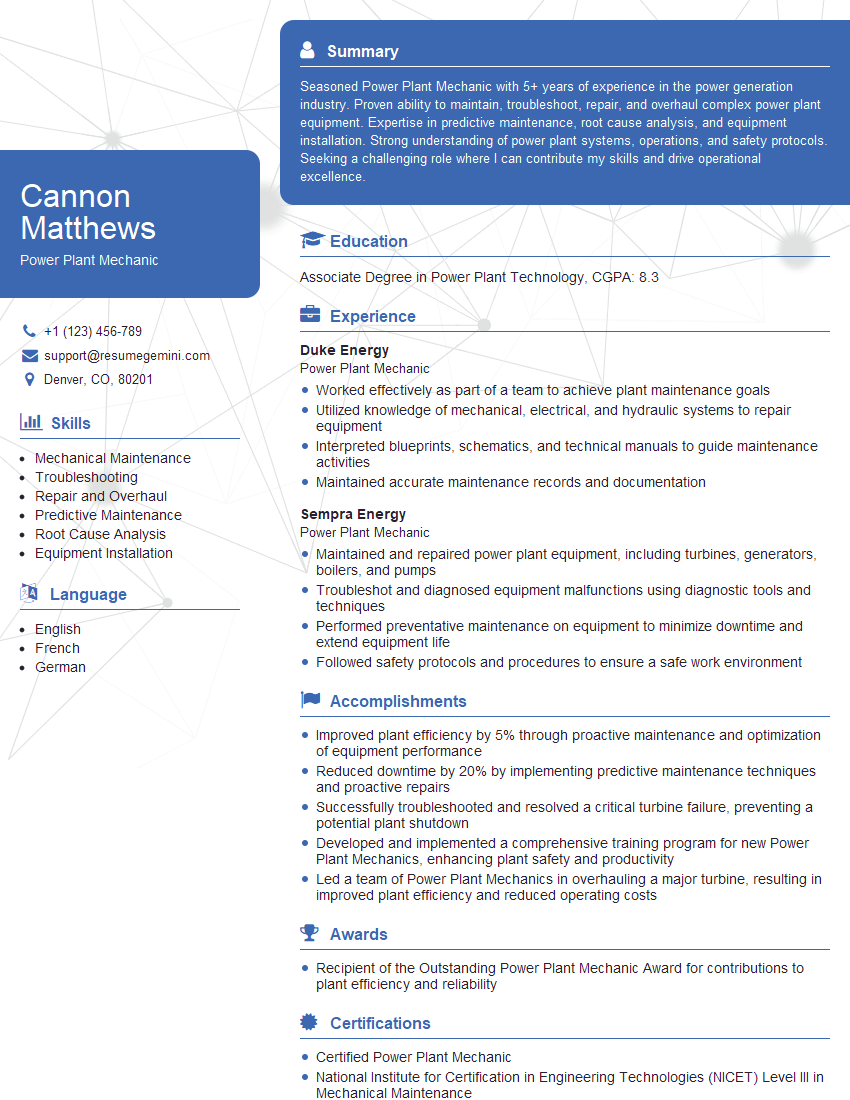

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Plant Mechanic

1. Describe the steps involved in troubleshooting a malfunctioning generator in a power plant?

As a Power Plant Mechanic, troubleshooting a malfunctioning generator requires a systematic approach. Here’s how I would navigate this process:

- Confirm the Malfunction: Verify the generator’s abnormal behavior and document the symptoms observed.

- Inspect the System: Physically examine the generator, connections, and associated components for any visible damage or irregularities.

- Review Logs and Records: Check maintenance logs, operating data, and any relevant documentation to identify potential anomalies.

- Test Electrical Parameters: Measure voltage, current, and resistance at various points in the generator’s electrical system to identify deviations.

- Inspect Mechanical Components: Examine bearings, seals, couplings, and other mechanical components for excessive wear, misalignment, or vibration.

- Analyze Data and Identify Cause: Based on the collected information, determine the root cause of the malfunction.

- Develop a Solution: Formulate a plan to repair or replace the affected components and restore the generator to proper operation.

2. How do you ensure the safe operation of high-voltage electrical equipment in a power plant?

Maintenance and Inspection:

- Regularly inspect equipment for damage, corrosion, or loose connections.

- Perform preventative maintenance, including cleaning, lubrication, and tightening.

Safety Procedures:

- Follow established safety protocols and wear appropriate personal protective equipment (PPE).

- Use insulated tools and maintain proper distances from energized components.

- Lock out and tag out equipment before performing any maintenance or repairs.

Training and Certification:

- Obtain and maintain relevant electrical safety certifications.

- Attend training programs to stay updated on industry best practices and regulations.

3. Describe the key components of a steam turbine and explain their functions?

- Rotor: The rotating part that drives the generator.

- Blades: Transfer energy from the steam to the rotor.

- Casing: Houses the rotor and blades and directs the steam flow.

- Valves: Control the flow of steam to the turbine.

- Bearings: Support the rotating shaft.

- Seals: Prevent steam leakage and maintain pressure.

4. Explain the importance of proper lubrication in power plant machinery?

Proper lubrication in power plant machinery is crucial for:

- Reducing Friction: Lubricants form a film between moving parts, reducing friction and wear.

- Cooling Components: Lubricants carry away heat generated by friction, preventing overheating.

- Protecting Against Corrosion: Lubricants create a barrier that protects metal surfaces from corrosion.

- Increased Efficiency: Reduced friction and smooth operation lead to improved efficiency and energy savings.

- Extended Equipment Life: Proper lubrication extends the life of machinery by reducing wear and preventing breakdowns.

5. How do you handle and store hazardous chemicals used in a power plant?

Handling:

- Wear appropriate personal protective equipment (PPE).

- Follow established safety protocols.

- Use approved containers and tools.

- Avoid spills and leaks.

Storage:

- Store chemicals in designated, secure areas.

- Maintain proper ventilation and temperature control.

- Inspect containers regularly for damage or leaks.

- Label chemicals clearly and provide safety information.

6. Describe the different types of welding processes used in power plant maintenance and repair?

Common welding processes used in power plant maintenance and repair include:

- Shielded Metal Arc Welding (SMAW): Stick welding, uses a consumable electrode.

- Gas Tungsten Arc Welding (GTAW): TIG welding, uses a non-consumable tungsten electrode and inert gas shielding.

- Gas Metal Arc Welding (GMAW): MIG welding, uses a consumable wire electrode and shielding gas.

- Flux-Cored Arc Welding (FCAW): Uses a tubular electrode that contains flux.

- Submerged Arc Welding (SAW): Uses a consumable electrode and granular flux that covers the weld area.

7. Explain the importance of preventive maintenance in power plant operations?

Preventive maintenance plays a vital role in power plant operations by:

- Preventing Equipment Failures: Regular inspections and maintenance reduce the risk of unexpected breakdowns.

- Extending Equipment Life: Proper care prolongs the lifespan of machinery and systems.

- Improving Efficiency: Well-maintained equipment operates at optimal efficiency, leading to energy savings.

- Reducing Maintenance Costs: Preventive maintenance can identify and address issues early on, preventing costly repairs.

- Ensuring Safety: Regularly servicing equipment ensures safe operation and minimizes safety risks.

8. Describe the safety protocols and procedures you follow when working in confined spaces in a power plant?

- Obtain proper authorization and follow lockout/tagout procedures.

- Conduct thorough hazard assessments and obtain air quality testing.

- Use proper personal protective equipment (PPE), including respirators if required.

- Establish communication and have a designated person outside the confined space.

- Monitor conditions, including air quality and temperature, throughout the duration of the work.

9. How do you stay updated on the latest technologies and advancements in power plant maintenance and repair?

- Attend industry conferences and training programs.

- Read trade publications and technical journals.

- Engage in online forums and discussion boards.

- Seek guidance from experienced professionals and mentors.

- Pursue professional certifications and licenses.

10. Have you faced any challenging situations while working as a Power Plant Mechanic? How did you overcome them?

In a previous role, I encountered a critical generator failure that threatened to disrupt power supply to a large section of the city. I followed a systematic troubleshooting approach, carefully inspecting all components and analyzing data. By isolating the faulty part and replacing it quickly, I restored generator operation within a minimal downtime, preventing a major power outage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Plant Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Plant Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Power Plant Mechanics are responsible for maintaining and repairing power plants and their equipment. They ensure that the plant operates safely and efficiently, and they work to prevent breakdowns and outages.

1. Maintenance and Repair

Power Plant Mechanics perform a variety of maintenance and repair tasks, including:

- Inspecting and cleaning equipment

- Lubricating and adjusting machinery

- Replacing worn or damaged parts

- Repairing electrical and mechanical systems

2. Troubleshooting

Power Plant Mechanics also troubleshoot problems with power plants and their equipment. They use their knowledge of the plant’s systems to identify and fix problems quickly and efficiently.

- Diagnosing problems with equipment

- Determining the cause of breakdowns

- Repairing or replacing damaged equipment

- Testing and calibrating equipment

3. Safety

Power Plant Mechanics must always follow safety procedures when working on power plants and their equipment. They must be aware of the potential hazards associated with their work, and they must take steps to protect themselves and others.

- Following safety procedures

- Wearing appropriate safety gear

- Working in a safe manner

- Reporting any unsafe conditions

4. Communication

Power Plant Mechanics must be able to communicate effectively with other members of the power plant team. They must be able to clearly explain their work to others, and they must be able to understand and follow instructions.

- Communicating with other team members

- Explaining their work to others

- Understanding and following instructions

- Reporting on the status of their work

Interview Tips

Preparing for a power plant mechanic interview can be a daunting task, but it’s important to remember that the interviewer is looking for someone who is qualified, experienced, and passionate about the job. By taking the time to prepare, you can increase your chances of making a good impression and landing the job.

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the specific requirements of the job.

- Visit the company’s website.

- Read about the company’s history, mission, and values.

- Learn about the specific position you’re applying for.

- Identify the key skills and experience required for the job.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself,” “Why are you interested in this job?” and “What are your strengths and weaknesses?” It’s important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself.

- Highlight your skills and experience that are relevant to the job.

- Explain why you’re interested in the job and the company.

- Be honest about your weaknesses, but focus on how you’re working to improve them.

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the job and that you respect their time.

- Wear clean, pressed clothes.

- Choose clothes that are appropriate for the work environment.

- Arrive for your interview 10-15 minutes early.

- Be polite and respectful to the receptionist and interviewer.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the job. They want to know that you’re excited about the opportunity to work for their company and that you’re confident in your abilities. Show the interviewer that you’re passionate about the job and that you’re eager to learn and grow.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic about the job.

- Show the interviewer that you’re eager to learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Power Plant Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.