Feeling lost in a sea of interview questions? Landed that dream interview for Power Saw Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Power Saw Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

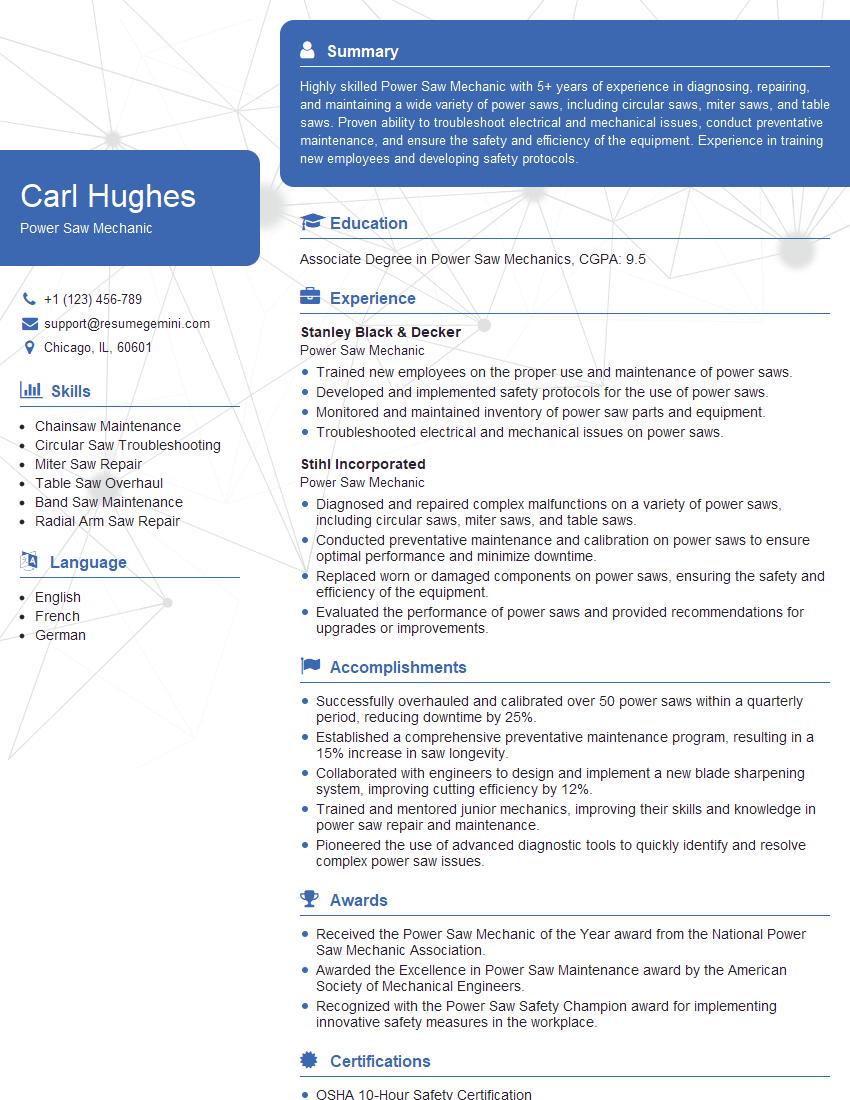

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Saw Mechanic

1. What are the different types of power saws and their applications?

- Circular saws: Used for cutting straight lines and curves in wood, metal, and plastic.

- Mitre saws: Used for making precise angled cuts, especially for mitre joints.

- Table saws: Used for making precise cuts in wood, often with jigs and fixtures.

- Jigsaw: Used for cutting intricate shapes and curves in wood, metal, and plastic.

- Reciprocating saws: Used for cutting through thick materials such as wood, metal, and pipes.

2. Describe the safety precautions that must be taken when operating power saws.

General precautions

- Wear appropriate safety gear, including eye protection, ear protection, gloves, and a dust mask.

- Inspect the saw and blades before use to ensure they are in good condition.

- Secure the workpiece properly to prevent it from moving during cutting.

- Maintain a firm grip on the saw and keep your hands clear of the cutting path.

Specific precautions

- For table saws, use a push stick to guide the workpiece through the blade.

- For mitre saws, ensure that the workpiece is securely clamped before cutting.

- For jigsaws, use a sharp blade and avoid cutting too quickly to prevent the blade from binding.

3. How do you troubleshoot and repair common problems with power saws?

Common problems

- Blade not cutting: Check the blade for dullness or damage, and replace if necessary. Ensure the blade is properly tensioned.

- Motor overheating: Allow the motor to cool down and check for any obstructions in the ventilation system. If the problem persists, it may indicate an electrical issue that requires professional repair.

- Saw not starting: Check the power cord and connections. Ensure the switch is functioning properly and that the motor brushes are not worn out.

Troubleshooting and repair

- Inspect the saw and identify the source of the problem.

- Refer to the manufacturer’s manual for specific troubleshooting and repair procedures.

- If the problem cannot be resolved, contact a qualified repair technician.

4. What are the different types of saw blades and their uses?

Types of saw blades

- Crosscut blades: Designed for cutting across the grain of the wood.

- Ripping blades: Designed for cutting with the grain of the wood.

- Combination blades: Designed for both crosscutting and ripping.

- Specialty blades: Designed for specific applications, such as cutting metal, plastic, or veneers.

Blade characteristics

- Tooth count: Higher tooth counts result in smoother cuts, while lower tooth counts provide faster cutting.

- Blade diameter: Larger blades allow for deeper cuts.

- Arbor size: The blade must match the arbor size of the saw.

5. How do you maintain and sharpen saw blades?

Maintenance

- Clean the blade regularly to remove sawdust and resin.

- Lubricate the blade according to the manufacturer’s instructions.

- Inspect the blade for signs of wear or damage, and replace as needed.

Sharpening

- Use a diamond-coated sharpening tool or file.

- Sharpen the blade at the proper angle and maintain a consistent bevel.

- After sharpening, deburr the blade to remove any sharp edges.

6. What are the different types of saw sharpening fixtures and their uses?

- Blade vice: Holds the blade securely while sharpening.

- Sharpening angle gauge: Ensures that the blade is sharpened at the proper angle.

- File guide: Guides the file or diamond tool along the blade edge.

- Joint/planer gauge: Used to align the blade with the jointing or planing machine.

7. How do you adjust the tension of a saw blade?

- Locate the tensioning mechanism on the saw.

- Use a blade tension gauge or follow the manufacturer’s instructions to determine the correct tension.

- Adjust the tension by tightening or loosening the tensioning screw or knob.

- Check the tension by plucking the blade and listening for a high-pitched tone.

8. What are the different types of saw guards and their purposes?

- Blade guard: Covers the blade to prevent accidental contact.

- Riving knife: Prevents the workpiece from pinching the blade and kicking back.

- Anti-kickback pawls: Prevent the workpiece from being thrown back at the operator.

- Splitter: Keeps the workpiece split behind the blade to prevent binding.

9. How do you perform basic maintenance and troubleshooting on a power saw motor?

Maintenance

- Clean the motor housing to remove sawdust and debris.

- Lubricate the motor bearings according to the manufacturer’s instructions.

- Inspect the motor brushes and replace them if they are worn out.

Troubleshooting

- Motor not starting: Check the power cord, connections, and switch. If the problem persists, it may indicate a more serious electrical issue.

- Motor overheating: Allow the motor to cool down and check for any obstructions in the ventilation system. If the problem persists, it may require professional repair.

- Motor running but not cutting: Check the blade for damage or dullness. Ensure the blade is properly installed and tensioned.

10. What are the different safety regulations and industry standards for power saw operation?

- Occupational Safety and Health Administration (OSHA) regulations

- American National Standards Institute (ANSI) standards

- Company-specific safety policies

- National Electrical Code (NEC) for electrical safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Saw Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Saw Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Power Saw Mechanics are responsible for maintaining, repairing, and overhauling power saws and other machinery. They must have a strong understanding of the mechanical principles of power saws, as well as the ability to diagnose and troubleshoot problems.

1. Maintenance and Repair

Power Saw Mechanics are responsible for performing scheduled maintenance on power saws, such as changing oil, sharpening blades, and adjusting chains. This helps to prevent breakdowns and extend the life of the saws.

- Inspect power saws for damage or wear and tear

- Clean and lubricate power saws

- Replace worn or damaged parts

2. Troubleshooting

Power Saw Mechanics must be able to diagnose and troubleshoot problems with power saws. This requires a strong understanding of the mechanical principles of saws and the ability to identify and resolve problems.

- Identify and diagnose problems with power saws

- Repair or replace faulty parts

- Test and calibrate power saws to ensure they are operating correctly

3. Overhauls

Power Saw Mechanics are responsible for overhauling power saws. This involves completely dismantling the saw, cleaning and inspecting all parts, and replacing any worn or damaged parts.

- Dismantle and reassemble power saws

- Inspect and clean all parts

- Replace worn or damaged parts

4. Safety

Power Saw Mechanics must follow all safety regulations when working with power saws. This includes wearing appropriate safety gear and using power saws in a safe manner.

- Follow all safety regulations when working with power saws

- Wear appropriate safety gear

- Use power saws in a safe manner

Interview Tips

Preparing for an interview for a Power Saw Mechanic position can be daunting, especially if you don’t know what to expect. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and what they’re looking for in a Power Saw Mechanic.

- Visit the company’s website

- Read online reviews of the company

- Talk to people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked in an interview for a Power Saw Mechanic position. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and closed-toe shoes.

- Wear a suit or dress pants and a button-down shirt

- Keep your hair neat and tidy

- Avoid wearing strong perfumes or colognes

4. Be Prepared to Talk About Your Experience

The interviewer will likely ask you about your experience as a Power Saw Mechanic. Be prepared to talk about your skills and experience in detail.

- Highlight your experience in maintaining and repairing power saws

- Discuss your troubleshooting skills

- Mention your experience in overhauling power saws

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Power Saw Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!