Are you gearing up for an interview for a Power Shovel Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Power Shovel Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

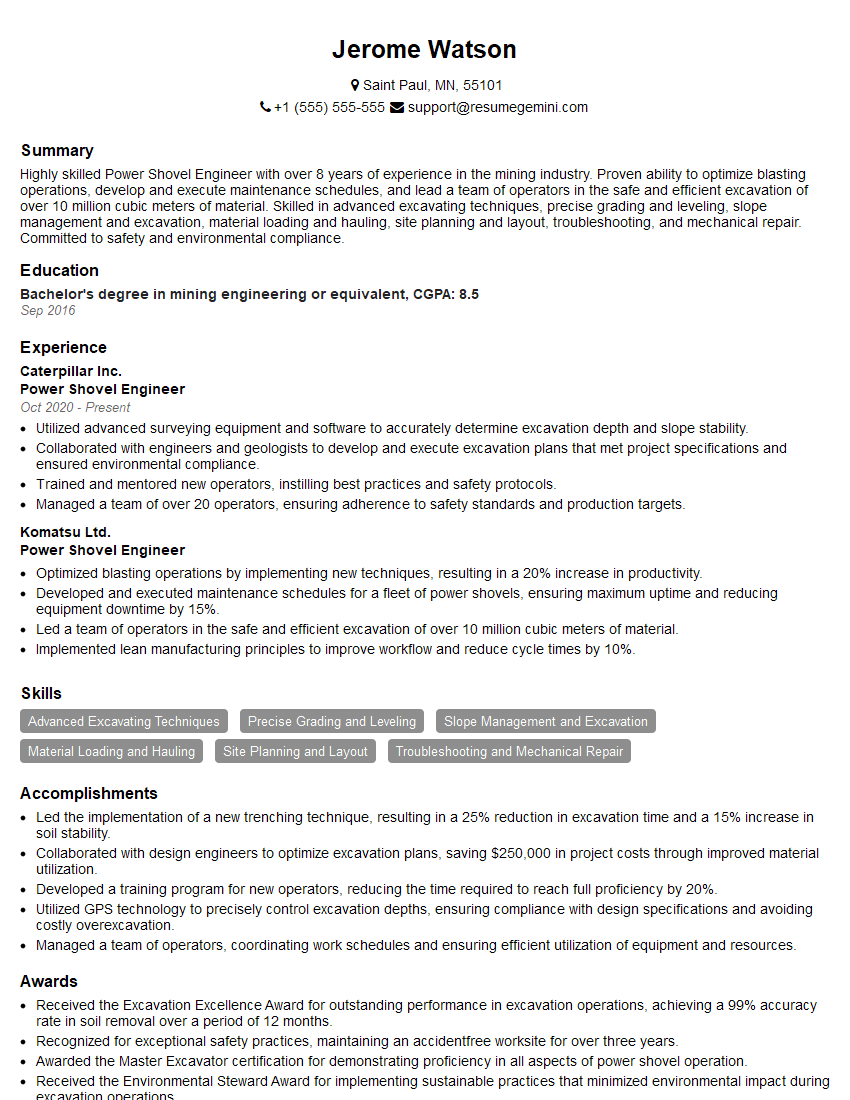

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Shovel Engineer

1. What are the key components of a power shovel and explain their functions?

The key components of a power shovel include:

- Boom: A long, articulated arm that supports the dipper and bucket.

- Dipper: A shorter arm attached to the boom that supports the bucket.

- Bucket: A scoop-shaped attachment that excavates material.

- Cab: An enclosed area where the operator sits and controls the shovel.

- Undercarriage: A tracked or wheeled base that supports the shovel and provides mobility.

- Hydraulic system: A network of pumps, valves, and hoses that provide power to the shovel’s components.

- Electrical system: A network of wires, switches, and relays that control the shovel’s operation.

2. Describe the process of excavating material using a power shovel.

Excavation Cycle

- The operator positions the shovel over the excavation area.

- The operator lowers the bucket into the ground.

- The operator curls the bucket to fill it with material.

- The operator raises the bucket and swings it over to the dump area.

- The operator dumps the material into the dump truck or pile.

Factors Affecting Excavation Efficiency

- Material type

- Ground conditions

- Shovel size and capacity

- Operator skill and experience

3. What are the different types of power shovels and their applications?

- Electric shovels: Powered by electricity and used in large-scale mining operations.

- Diesel shovels: Powered by diesel engines and used in smaller mining operations and construction projects.

- Hydraulic shovels: Powered by hydraulic systems and used in a wide range of applications, including mining, construction, and demolition.

- Backhoe shovels: Combine a power shovel with a backhoe attachment, providing versatility for excavation and trenching operations.

- Dragline shovels: Used for long-distance excavation, such as creating canals and levees.

4. Explain the importance of proper maintenance for power shovels.

Proper maintenance is crucial for power shovels to ensure:

- Safety: Regular inspections and maintenance help prevent failures and accidents.

- Reliability: Scheduled maintenance tasks prolong the shovel’s lifespan and minimize downtime.

- Performance: Well-maintained shovels operate efficiently and at peak capacity.

- Cost-effectiveness: Preventive maintenance reduces the risk of major repairs and costly breakdowns.

5. Describe the safety precautions that should be followed when operating a power shovel.

- Wear appropriate safety gear (hard hat, safety glasses, gloves, etc.).

- Inspect the shovel thoroughly before each use.

- Maintain a safe distance from other equipment and personnel.

- Be aware of overhead power lines and other potential hazards.

- Never leave the shovel running unattended.

- Follow established safety protocols and procedures.

6. What are the different types of ground conditions that can affect power shovel operation?

- Hard ground: Requires more power to excavate and can put stress on the shovel’s components.

- Soft ground: May require the use of mats or pads to prevent the shovel from sinking in.

- Wet ground: Can reduce traction and make it difficult to operate the shovel safely.

- Frozen ground: Requires specialized equipment and techniques to excavate.

- Sloped ground: Requires careful operation to avoid tipping or sliding.

7. Explain the use of attachments in power shovel operations.

- Buckets: Different types and sizes of buckets are used for various materials and excavation tasks.

- Rippers: Attachments used to break up hard or compacted ground.

- Thumbs: Attachments that provide additional grip and stability when handling materials.

- Grapples: Attachments used to grab and move large objects or debris.

- Hydraulic hammers: Attachments used for breaking concrete or rock.

8. Describe the role of technology in modern power shovels.

- GPS and laser guidance systems: Enhance accuracy and efficiency during excavation.

- Remote control systems: Allow operators to control the shovel from a safe distance.

- Diagnostic systems: Monitor the shovel’s performance and identify potential problems.

- Automated excavation systems: Enable shovels to perform complex tasks autonomously.

9. What are the key factors to consider when selecting a power shovel for a specific project?

- Size and capacity: Must match the project’s excavation requirements.

- Type of material: Different materials require different types of buckets and attachments.

- Ground conditions: Must be compatible with the shovel’s undercarriage and capabilities.

- Budget: Must consider both the purchase price and ongoing operating costs.

- Availability: Ensure the shovel is available during the project timeframe.

10. How do you stay updated on the latest advancements in power shovel technology?

- Attend industry conferences and trade shows.

- Read technical publications and journals.

- Network with other power shovel engineers and operators.

- Research and explore new technologies online.

- Consult with manufacturers and distributors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Shovel Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Shovel Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Power Shovel Engineer is responsible for the safe and efficient operation of power shovels, including performing maintenance, troubleshooting, and repairs. They must also be able to work independently and as part of a team, and must have a strong understanding of the principles of power shovels and their operation.

1. Operation

The Power Shovel Engineer is responsible for the safe and efficient operation of power shovels, including:

- Excavating and loading materials

- Grading and leveling surfaces

- Digging trenches and foundations

- Positioning and setting up the power shovel

2. Maintenance

The Power Shovel Engineer is responsible for performing maintenance on power shovels, including:

- Inspecting and cleaning the power shovel

- Lubricating and replacing parts

- Making minor repairs

3. Troubleshooting

The Power Shovel Engineer is responsible for troubleshooting and repairing power shovels, including:

- Diagnosing problems

- Repairing or replacing parts

- Testing the power shovel to ensure it is working properly

4. Safety

The Power Shovel Engineer is responsible for ensuring that the power shovel is operated safely, including:

- Following all safety procedures

- Wearing appropriate safety gear

- Ensuring that the work area is clear of hazards

Interview Tips

To prepare for an interview for a Power Shovel Engineer position, you should:

1. Research the company and the position

This will give you a better understanding of the company’s culture and values, as well as the specific requirements of the position. You can find information about the company on its website, social media pages, and Glassdoor.

2. Practice answering common interview questions

Some common interview questions for Power Shovel Engineer positions include:

- Tell me about your experience operating power shovels.

- What are the most important safety considerations when operating a power shovel?

- How do you troubleshoot and repair power shovels?

3. Highlight your skills and experience

Make sure to highlight your skills and experience that are relevant to the position. For example, if you have experience operating a specific type of power shovel, be sure to mention that in your resume and cover letter.

4. Be prepared to talk about your safety record

Safety is a top priority for Power Shovel Engineers, so be prepared to talk about your safety record in your interview. Mention any safety awards or recognition you have received, and be sure to emphasize your commitment to safety.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Power Shovel Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!