Are you gearing up for an interview for a Power Tool Repair Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Power Tool Repair Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

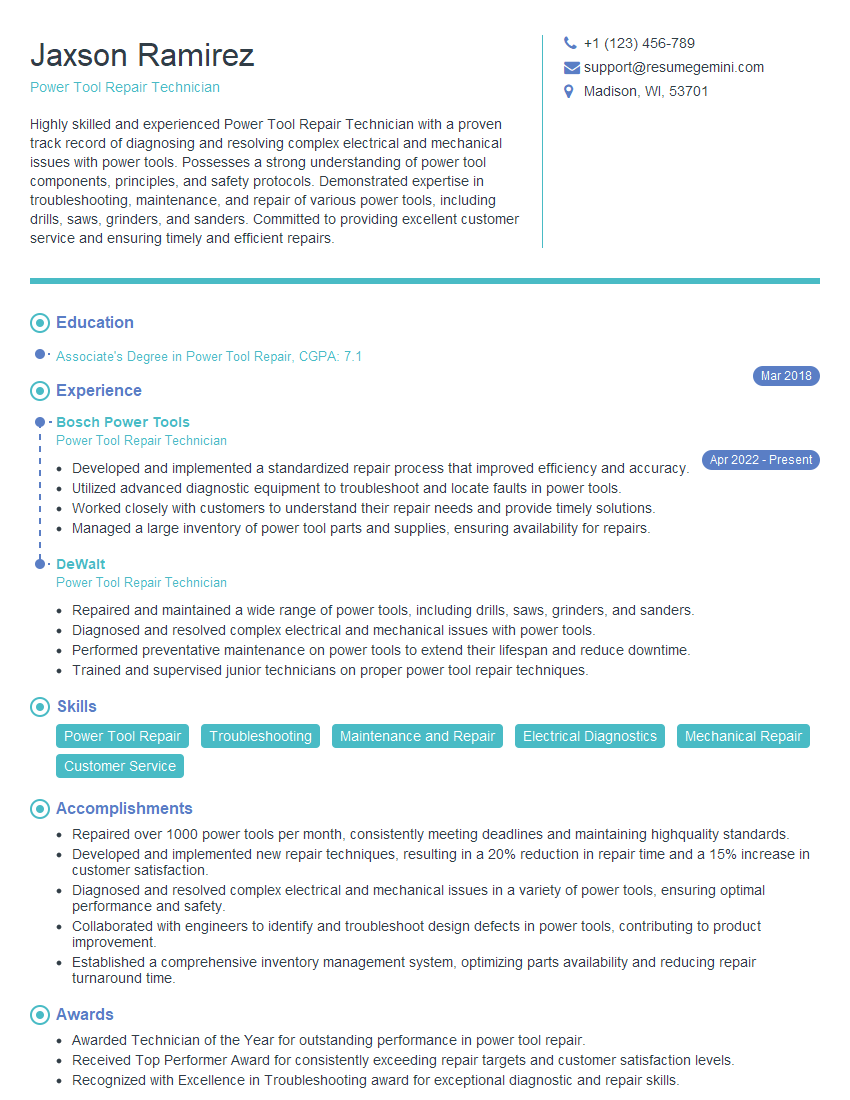

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Power Tool Repair Technician

1. What are the different types of power tools that you are familiar with repairing?

I have experience repairing a wide range of power tools, including drills, saws, sanders, grinders, and impact wrenches. I am also familiar with the different types of power sources used in power tools, including electric, pneumatic, and hydraulic.

2. What are the most common problems that you encounter when repairing power tools?

Electrical problems

- Faulty wiring

- Blown fuses

- Bad switches

Mechanical problems

- Worn gears

- Bent shafts

- Damaged bearings

Other problems

- Overheating

- Vibration

- Noise

3. What are the steps involved in troubleshooting a power tool?

The steps involved in troubleshooting a power tool typically include the following:

- Identifying the problem

- Inspecting the power tool

- Testing the power tool

- Diagnosing the problem

- Repairing the power tool

4. What are the safety precautions that you take when repairing power tools?

The safety precautions that I take when repairing power tools include the following:

- Wearing appropriate safety gear, such as safety glasses, gloves, and earplugs

- Unplugging the power tool before starting any repairs

- Using the correct tools for the job

- Being aware of my surroundings and potential hazards

- Following all applicable safety regulations

5. What are the different types of power tool repair tools that you are familiar with?

The different types of power tool repair tools that I am familiar with include the following:

- Hand tools, such as screwdrivers, wrenches, and pliers

- Power tools, such as drills, saws, and grinders

- Diagnostic tools, such as multimeters and oscilloscopes

- Specialty tools, such as arbor presses and bearing pullers

6. What is your experience with repairing power tools that are used in hazardous environments?

I have experience repairing power tools that are used in hazardous environments, such as construction sites and industrial settings. I am familiar with the safety precautions that need to be taken when repairing these types of power tools.

7. What is your experience with repairing power tools that are used in the medical field?

I have experience repairing power tools that are used in the medical field, such as surgical drills and bone saws. I am familiar with the special requirements that these types of power tools must meet, such as being able to withstand high levels of sterilization.

8. What is your experience with repairing power tools that are used in the automotive industry?

I have experience repairing power tools that are used in the automotive industry, such as impact wrenches and air compressors. I am familiar with the different types of power tools that are used in this industry and the specific requirements that they must meet.

9. What is your experience with repairing power tools that are used in the aerospace industry?

I have experience repairing power tools that are used in the aerospace industry, such as torque wrenches and rivet guns. I am familiar with the special requirements that these types of power tools must meet, such as being able to withstand high levels of vibration and temperature.

10. What are your career goals?

My career goals include becoming a master power tool repair technician and eventually opening my own power tool repair shop. I am also interested in developing new and innovative power tool repair techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Power Tool Repair Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Power Tool Repair Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a highly skilled Power Tool Repair Technician, you’ll be responsible for diagnosing, repairing, and maintaining a wide range of power tools. Your superior technical abilities and commitment to quality will ensure that all tools are in peak condition.

1. Diagnose and Repair Power Tools

Thoroughly evaluate power tools to identify malfunctions or defects using advanced diagnostic techniques

- Utilize technical manuals and schematics to pinpoint the source of problems

- Disassemble and reassemble tools to access and repair damaged components

2. Calibrate and Test Power Tools

Ensure precision and accuracy by calibrating power tools according to manufacturer’s specifications

- Conduct thorough testing to verify functionality and performance

- Maintain accurate records of calibration and testing results

3. Inspect and Maintain Power Tools

Regularly inspect power tools to identify potential issues and prevent breakdowns

- Clean, lubricate, and adjust tools to extend their lifespan

- Identify and replace worn or damaged parts promptly

4. Provide Technical Support

Offer expert guidance to users on proper tool usage, maintenance, and safety measures

- Respond to inquiries and provide prompt solutions

- Train users on safe and efficient tool handling practices

Interview Tips

To ace the interview for a Power Tool Repair Technician position, consider these tips:

1. Research the Company and Industry

Demonstrate your interest and enthusiasm by familiarizing yourself with the company’s products, services, and industry trends

- Visit the company’s website and social media pages

- Read industry publications and articles

2. Highlight Your Technical Skills

Emphasize your proficiency in diagnosing and repairing power tools, as well as your knowledge of electrical systems and mechanical components

- Quantify your accomplishments with specific examples

- Discuss your experience with different types of power tools

3. Showcase Your Problem-Solving Abilities

Provide instances where you successfully resolved complex power tool issues. Describe your analytical process and the steps you took to reach a solution

- Use the STAR method to structure your responses

- Highlight your ability to think critically and find creative solutions

4. Emphasize Your Commitment to Quality

Stress your dedication to delivering high-quality repairs and ensuring that power tools meet industry standards

- Discuss your adherence to safety protocols

- Explain how you ensure accuracy and precision in your work

5. Practice Your Communication Skills

Practice articulating your technical knowledge and explaining complex concepts clearly to both technical and non-technical audiences

- Prepare for questions about your communication style

- Be confident in your ability to convey information effectively

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Power Tool Repair Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!