Are you gearing up for an interview for a Powerhouse Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Powerhouse Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

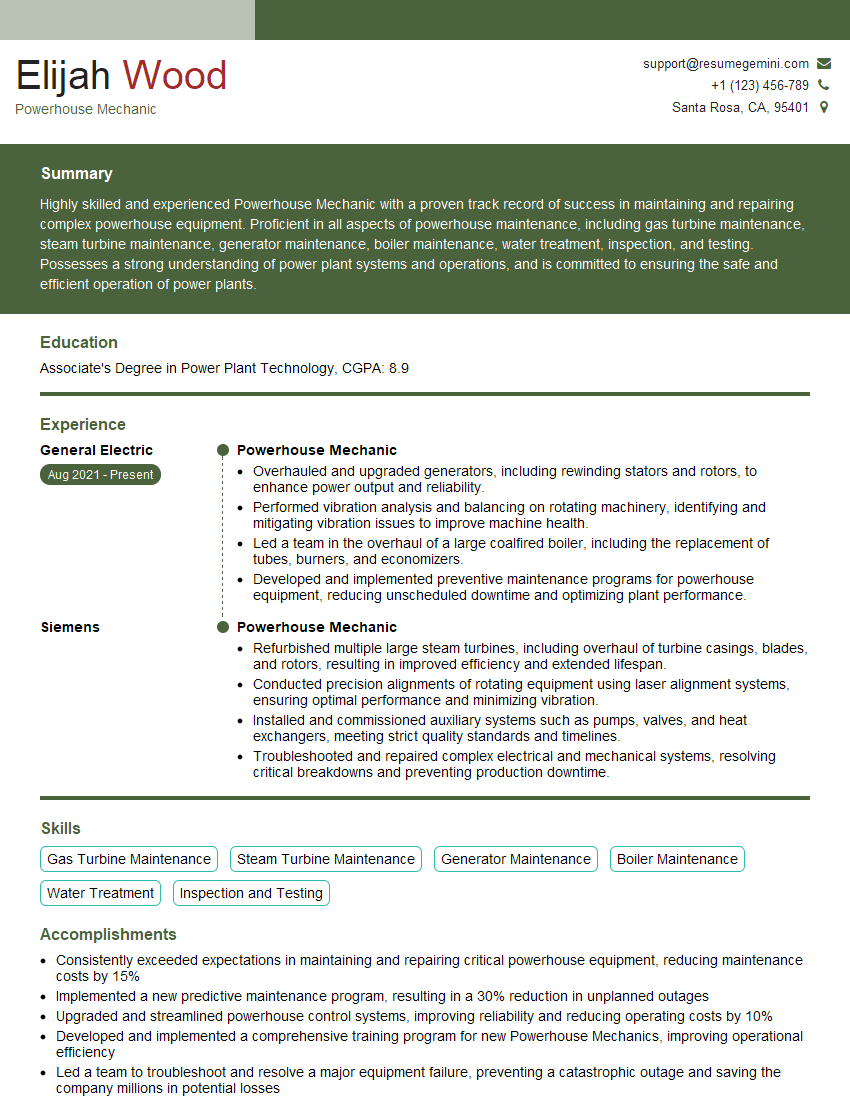

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Powerhouse Mechanic

1. What are the key responsibilities of a Powerhouse Mechanic?

As a Powerhouse Mechanic, I would be responsible for:

- Inspecting, maintaining, and repairing a variety of mechanical equipment, including engines, generators, pumps, and turbines.

- Conducting scheduled maintenance and repairs, as well as troubleshooting and diagnosing problems.

- Installing and assembling new equipment, and making adjustments and modifications to existing equipment.

- Performing preventive maintenance tasks, such as lubricating, cleaning, and replacing parts, to ensure the smooth operation of equipment.

- Working with electrical systems, including wiring, controls, and instrumentation.

2. What are the different types of engines you have worked on?

Diesel Engines

- I have extensive experience in servicing and repairing diesel engines, including Cummins, Caterpillar, and Detroit Diesel.

- I am familiar with the various components of diesel engines, such as fuel systems, cooling systems, and electrical systems.

Gasoline Engines

- I have also worked on gasoline engines, including those found in cars, trucks, and boats.

- I am proficient in diagnosing and repairing ignition systems, fuel systems, and emission control systems.

3. What are your experiences working with generators?

I have significant experience working with generators, including:

- Troubleshooting and repairing generators, including diesel and gasoline generators.

- Performing scheduled maintenance on generators, such as changing oil and filters, and inspecting components.

- Testing and calibrating generators to ensure they are operating at optimal performance.

- Installing and commissioning new generators, as well as connecting them to electrical systems.

4. How do you troubleshoot electrical problems in a powerhouse?

When troubleshooting electrical problems in a powerhouse, I follow a systematic approach:

- First, I identify the symptoms of the problem, such as power outages, equipment malfunctions, or abnormal readings on instruments.

- Next, I inspect the electrical system to look for any obvious problems, such as loose connections, damaged wires, or faulty components.

- If I cannot find any obvious problems, I use diagnostic tools, such as multimeters and oscilloscopes, to identify the root cause of the issue.

- Once I have identified the problem, I make the necessary repairs or replacements to resolve the issue.

5. What are the safety precautions you take when working on electrical equipment?

When working on electrical equipment, I always prioritize safety by:

- Wearing appropriate personal protective equipment (PPE), such as insulated gloves, safety glasses, and a hard hat.

- Ensuring that the equipment is properly de-energized before performing any work.

- Using insulated tools and following proper grounding procedures.

- Being aware of the potential hazards of electrical equipment, such as electrical shocks and arc flashes.

6. What are the different types of lubrication systems used in powerhouses?

There are several types of lubrication systems used in powerhouses, including:

- Oil Bath Lubrication: This system uses an oil bath to lubricate bearings and gears. The components are submerged in oil, which provides lubrication and cooling.

- Grease Lubrication: This system uses grease to lubricate bearings and gears. Grease is applied to the components manually or through an automated system.

- Circulating Oil Lubrication: This system uses a pump to circulate oil throughout the system. The oil is filtered and cooled before being circulated.

- Mist Lubrication: This system uses a fine mist of oil to lubricate bearings and gears. The mist is generated by a compressor and distributed through a network of pipes.

7. How do you align a pump and motor?

To align a pump and motor, I follow these steps:

- Rough Alignment: I first perform a rough alignment using a straightedge and feeler gauges to ensure that the pump and motor are parallel and at the correct height.

- Fine Alignment: Once the rough alignment is complete, I use a dial indicator to fine-tune the alignment. I check the alignment in both the horizontal and vertical planes.

- Coupling Installation: After the alignment is complete, I install the coupling between the pump and motor.

8. What is the purpose of a vibration analysis?

A vibration analysis is performed to:

- Identify potential problems with rotating equipment, such as imbalances, misalignments, and bearing faults.

- Monitor the condition of equipment and predict potential failures.

- Evaluate the effectiveness of maintenance and repair work.

9. What are the common causes of vibration in rotating equipment?

Common causes of vibration in rotating equipment include:

- Imbalance: An imbalance occurs when the mass of the rotating component is not evenly distributed.

- Misalignment: Misalignment occurs when the shafts of the rotating components are not aligned properly.

- Bearing Faults: Bearing faults can cause vibration due to excessive wear, contamination, or misalignment.

- Looseness: Looseness in the foundation or крепления can also cause vibration.

- Resonance: Resonance occurs when the operating frequency of the equipment matches the natural frequency of a component.

10. How do you balance a rotating component?

To balance a rotating component, I use a balancing machine:

- Initial Setup: I first mount the component on the balancing machine and secure it in place.

- Measurement: The machine rotates the component and measures the vibration at different points.

- Correction: The machine then calculates the amount and location of the correction weight required to balance the component.

- Weight Addition: I add the correction weight to the component at the specified location.

- Re-Measurement: I re-measure the vibration to ensure the component is balanced.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Powerhouse Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Powerhouse Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Equipment Maintenance and Repair

Performing routine inspections of power plant equipment, including boilers, turbines, pumps, valves, and piping systems.

2. Troubleshooting and Problem Solving

Identifying and resolving equipment malfunctions promptly and efficiently

3. Preventive Maintenance

Developing and implementing preventive maintenance programs to ensure smooth plant operation, reduce downtimes, and extend equipment life.

4. Safety Compliance

Ensuring adherence to safety regulations, including OSHA and EPA standards, as well as the company’s safety policies.

5. Record Keeping

Maintaining accurate records of maintenance and repair work performed, including equipment history, test results, and maintenance schedules.

Interview Tips

1. Research the Company and Industry

Familiarize yourself with the company’s website, industry news, and recent developments in the power generation field.

2. Highlight Relevant Skills and Experience

Clearly articulate your skills in equipment maintenance, troubleshooting, and preventive maintenance. Emphasize any specific certifications or training programs you have completed.

3. Prepare for Technical Questions

Expect questions about power plant equipment, maintenance procedures, and industry best practices. Be prepared to provide detailed answers and share examples of your work.

4. Show Enthusiasm and Passion

Convey your interest in the role and your dedication to maintaining reliable power generation equipment. Share examples of your willingness to go the extra mile to ensure plant safety and efficiency.

5. Ask Insightful Questions

Asking intelligent questions during the interview demonstrates your interest and eagerness to learn. Prepare questions about the company’s maintenance practices, equipment upgrades, or safety initiatives.

6. Practice Your Answers

Rehearse your answers to common interview questions and mock interviews to gain confidence and improve your delivery.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Powerhouse Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!