Are you gearing up for an interview for a Pre-Assembly Printed Circuit Board Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pre-Assembly Printed Circuit Board Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

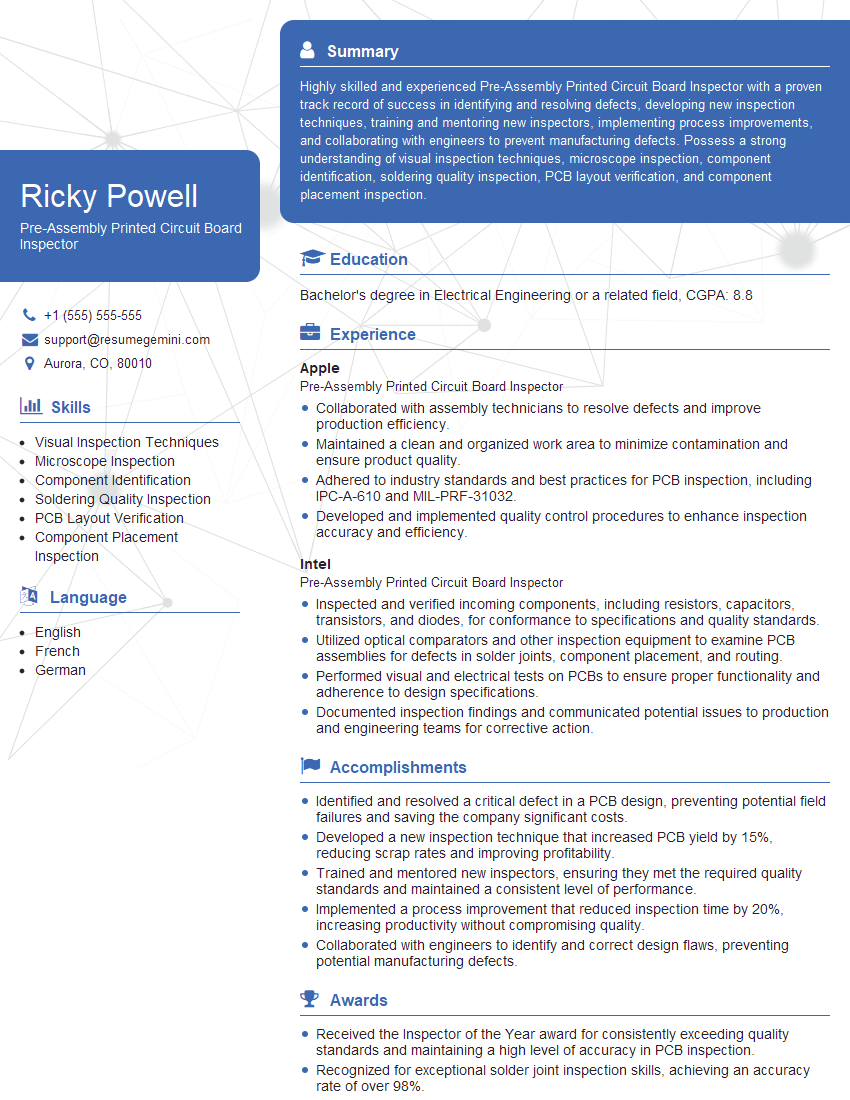

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pre-Assembly Printed Circuit Board Inspector

1. What are the key responsibilities of a Pre-Assembly Printed Circuit Board (PCB) Inspector?

- Inspect and verify the physical characteristics of pre-assembled PCBs to ensure conformity with design specifications and industry standards.

- Identify and document any defects or non-conformances, including scratches, dents, solder joints, and component placement errors.

- Use measuring and testing equipment to check electrical continuity, resistance, and other electrical parameters.

- Inspect for proper component identification, marking, and orientation.

- Maintain accurate inspection records and documentation, including defect reports and corrective action plans.

2. Describe the inspection process for pre-assembled PCBs.

Visual Inspection

- Examine the PCB for physical defects, such as scratches, dents, and solder joints.

- Check for proper component placement, orientation, and identification.

- Verify the presence and absence of components according to the design specifications.

Electrical Test

- Use a multimeter to measure electrical continuity, resistance, and other electrical parameters.

- Check for short circuits, open circuits, and other electrical faults.

- Verify the functionality of the PCB by testing it with a power supply and signal generator.

3. What are the most common defects found during pre-assembly PCB inspection?

- Solder joint defects (e.g., cold solder joints, excessive solder, solder bridges)

- Component placement errors (e.g., misalignment, incorrect orientation)

- Component damage (e.g., broken leads, cracked components)

- PCB damage (e.g., scratches, dents, corrosion)

- Missing or extra components

4. What are the industry standards and regulations that apply to pre-assembly PCB inspection?

- IPC-610: Acceptability of Electronic Assemblies

- IPC-A-610: Acceptability of Printed Circuit Boards

- ISO 9001: Quality Management Systems

- RoHS (Restriction of Hazardous Substances)

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

5. How do you stay updated with the latest industry best practices and technologies for PCB inspection?

- Attend industry conferences and workshops.

- Read industry publications and technical journals.

- Participate in online forums and discussion groups.

- Obtain industry certifications (e.g., IPC-A-610 Certified Inspector).

- Network with other PCB inspectors and industry professionals.

6. What is your experience with using inspection equipment, such as microscopes, calipers, and multimeters?

- Demonstrate proficiency in using microscopes to inspect solder joints, component placement, and PCB traces.

- Show experience in using calipers to measure component dimensions and PCB clearances.

- Explain how you use multimeters to test electrical continuity, resistance, and other electrical parameters.

7. How do you handle situations where you identify non-conformances or defects during inspection?

- Document the non-conformance or defect clearly and accurately.

- Communicate the findings to the appropriate personnel (e.g., manufacturing, quality control, engineering).

- Assist in developing and implementing corrective action plans.

- Follow up to ensure that corrective actions have been implemented effectively.

8. How do you prioritize inspection tasks when there are multiple PCBs to be inspected?

- Establish clear inspection criteria and priorities based on factors such as product criticality, customer requirements, and production schedule.

- Use a systematic approach to ensure that all PCBs are inspected thoroughly.

- Communicate inspection priorities to team members and coordinate with other departments to ensure efficient workflow.

9. How do you ensure the accuracy and consistency of your inspection results?

- Follow established inspection procedures and checklists.

- Use calibrated and reliable inspection equipment.

- Receive regular training and participate in proficiency testing programs.

- Periodically review and update inspection criteria to ensure alignment with industry best practices.

10. How do you handle situations where you encounter complex or unusual defects during inspection?

- consult with experienced colleagues or supervisors for guidance.

- refer to technical documentation or industry resources for additional information.

- Conduct further investigation using advanced inspection techniques or specialized equipment.

- Collaborate with engineering or design teams to troubleshoot and resolve the issue.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pre-Assembly Printed Circuit Board Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pre-Assembly Printed Circuit Board Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pre-Assembly Printed Circuit Board Inspectors play a crucial role in ensuring the quality and reliability of electronic devices. Their primary responsibilities include:

1. Visual Inspection

Inspecting incoming PCBs for defects, such as solder joints, shorts, opens, and component placement.

- Using magnifying glasses, microscopes, and other optical tools to examine circuit boards.

- Identifying and documenting any deviations from established specifications.

2. Electrical Testing

Conducting electrical tests to verify the functionality and performance of PCBs.

- Using oscilloscopes, multimeters, and other test equipment to measure electrical parameters.

- Testing for continuity, insulation resistance, and other electrical properties.

3. Component Verification

Ensuring that all components on the PCB are present, correctly installed, and meet specifications.

- Comparing components to approved lists and documentation.

- Identifying and reporting any discrepancies or missing components.

4. Process Documentation

Recording and maintaining inspection results and any identified defects.

- Completing inspection reports and test records.

- Working with production and quality assurance teams to resolve any issues identified.

Interview Tips

To prepare for an interview for a Pre-Assembly Printed Circuit Board Inspector position, it is important to:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and values.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on trends and technologies.

2. Brush up on Technical Skills

Review your knowledge of electrical testing, component verification, and quality control standards.

- Focus on understanding the principles behind the inspection techniques used.

- Practice using inspection equipment and documenting results.

3. Prepare for Behavioral Questions

Be ready to discuss your work experience, teamwork skills, and attention to detail.

- Use the STAR method (Situation, Task, Action, Result) to answer questions.

- Highlight specific examples of your successes and contributions.

4. Demonstrate Your Passion and Commitment

Express your interest in the role and the industry, and explain why you are a good fit for the position.

- Share your motivations for pursuing a career in electronics inspection.

- Emphasize your commitment to quality and accuracy.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pre-Assembly Printed Circuit Board Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!