Are you gearing up for a career in Precast Concrete Ironworker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Precast Concrete Ironworker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

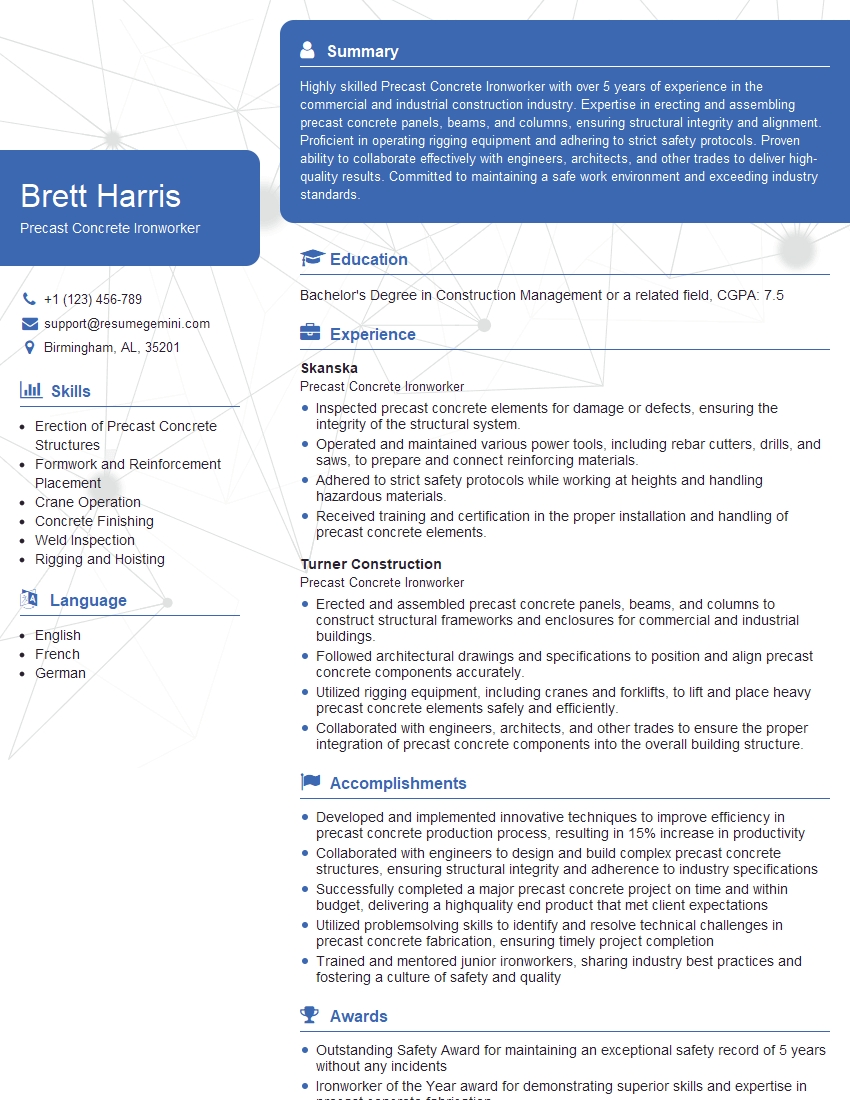

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precast Concrete Ironworker

1. Can you describe the process of erecting precast concrete panels?

- Begin by lifting the panel into place using a crane.

- Set the panel on temporary supports, plumb, and level it.

- Attach the panel to the structure using bolts or welding, depending on the design.

- Remove the temporary supports once the panel is securely fastened.

- Inspect the panel for any damage and make any necessary repairs.

2. What safety precautions should be taken when working with precast concrete?

Handling

- Wear appropriate PPE: hard hat, safety glasses, gloves, and steel-toed boots.

- Inspect the panel for any damage or defects before lifting.

- Use proper lifting equipment and techniques to avoid injuries.

- Never lift a panel that is too heavy for you.

- Be aware of your surroundings and potential hazards.

Installation

- Check the panel’s dimensions and weight to ensure it is correct.

- Determine the proper location for the panel and mark it.

- Set the panel on temporary supports and adjust it to the correct position.

- Attach the panel to the structure securely using bolts or welding.

- Remove the temporary supports once the panel is securely fastened.

3. What are the different types of reinforcement used in precast concrete and their properties?

- Steel reinforcing bars (rebar): Provide tensile strength and are available in various grades and sizes.

- Welded wire fabric: A mesh of steel wires welded together, used to reinforce flat slabs and walls.

- Fiber reinforcement: Small fibers (steel, glass, or synthetic) added to the concrete mix to improve its tensile strength, toughness, and crack resistance.

- Prestressed concrete: High-strength steel tendons are tensioned and embedded in the concrete, creating compressive forces that increase its strength.

4. Can you explain the quality control measures in place for precast concrete production?

- Material testing: Test concrete mix, reinforcing steel, and other materials to ensure they meet specifications.

- Form inspection: Check forms for accuracy and cleanliness before casting concrete.

- Concrete casting: Monitor concrete placement, vibration, and curing conditions.

- Curing: Control temperature and moisture during curing to ensure proper strength development.

- Final inspection: Visually inspect panels for defects, measure dimensions, and test strength before shipping.

5. What are the challenges of working as a precast concrete ironworker and how do you overcome them?

- Heavy lifting: Regularly lift and move heavy concrete panels.

- Working at heights: Install panels on elevated structures, requiring proper safety equipment and training.

- Weather conditions: Work in various weather conditions, including rain, snow, and extreme temperatures.

- Time constraints: Meet project deadlines while ensuring quality of work.

Overcoming the challenges

- Use proper lifting equipment and techniques.

- Follow safety procedures and wear appropriate PPE.

- Plan work ahead to minimize time constraints.

- Continuously improve skills and knowledge.

6. What is your experience in reading and interpreting construction drawings and specifications for precast concrete?

- Understanding symbols and abbreviations: Familiar with industry-standard symbols and abbreviations used in drawings.

- Reading plan views: Interpret drawings to visualize the layout and dimensions of structures and precast elements.

- Understanding elevations and sections: Analyze drawings to determine the vertical relationships and details of precast components.

- Extracting relevant information: Identify key dimensions, reinforcement details, and installation requirements from specifications.

7. Can you describe your experience with different types of precast concrete products?

- Architectural panels: Installed precast concrete panels as exterior cladding and interior walls.

- Structural elements: Worked with precast beams, columns, and slabs to create structural frames for buildings.

- Site elements: Installed precast pavers, curbs, and retaining walls for landscaping and infrastructure.

8. What are the different types of connections used in precast concrete construction, and how do you select the appropriate connection for a specific application?

- Grouted connections: Use grout to fill gaps between precast elements, providing a strong and durable connection.

- Bolted connections: Connect precast elements using high-strength bolts, allowing for easy disassembly if necessary.

- Welded connections: Weld precast elements together to create permanent and robust connections.

- Post-tensioned connections: Use post-tensioning cables to apply compressive forces and create strong connections between precast elements.

Selection criteria

- Structural requirements (load capacity, ductility)

- Project budget and time constraints

- Site conditions (access, available equipment)

- Future maintenance and repair considerations

9. How do you ensure accuracy and quality in your work as a precast concrete ironworker?

- Attention to detail: Pay meticulous attention to dimensions, alignment, and other critical details.

- Use of measuring and leveling instruments: Utilize levels, transits, and other tools to ensure proper positioning and alignment.

- Following established procedures: Adhere to standardized installation procedures to ensure consistent results.

- Regular inspections: Conduct regular inspections throughout the installation process to identify and correct any errors.

- Customer feedback: Seek feedback from supervisors and clients to identify areas for improvement.

10. What are the latest advancements or trends in the precast concrete industry, and how have they impacted your work?

- High-performance concrete: Utilizes advanced materials and techniques to improve strength, durability, and aesthetics.

- Prefabricated elements: Complete precast components, such as modular buildings and bridge decks, reduce on-site assembly time.

- Digital technologies: Uses 3D modeling, BIM, and other technologies to enhance design, engineering, and fabrication processes.

- Sustainable practices: Focuses on reducing environmental impact through eco-friendly materials and processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precast Concrete Ironworker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precast Concrete Ironworker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Precast Concrete Ironworkers are responsible for the fabrication, installation, and maintenance of precast concrete products. Their duties include:

1. Fabrication

Fabricating precast concrete products in accordance with blueprints and specifications.

- Setting up and operating concrete forms.

- Pouring and finishing concrete.

- Curing and stripping precast concrete products.

2. Installation

Installing precast concrete products on construction sites.

- Erecting precast concrete panels and beams.

- Grouting and sealing precast concrete joints.

- Inspecting precast concrete products for damage.

3. Maintenance

Maintaining precast concrete products.

- Cleaning and repairing precast concrete surfaces.

- Inspecting precast concrete products for signs of deterioration.

- Replacing damaged precast concrete products.

4. Other Duties

Performing other duties as assigned, such as:

- Loading and unloading precast concrete products.

- Operating forklifts and other equipment.

- Assisting with the design and engineering of precast concrete products.

Interview Tips

Here are some tips to help you ace your interview for a Precast Concrete Ironworker position:

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand their business, their culture, and their needs. You can find information about the company on their website, social media pages, and news articles.

- Know the company’s history, mission, and values.

- Research the company’s products or services.

- Identify any recent news or events related to the company.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with precast concrete?

- How do you handle working in a team environment?

Take some time to practice answering these questions out loud. This will help you feel more confident and prepared during your interview.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also avoid wearing any clothing that is too revealing, too casual, or too distracting.

4. Be Punctual

Punctuality is a sign of respect, so it is important to arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

5. Be Prepared to Ask Questions

Asking questions at the end of your interview shows that you are interested in the position and that you have taken the time to prepare. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

- What is the company culture like?

- What are the next steps in the interview process?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Precast Concrete Ironworker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!