Are you gearing up for a career in Precast Concrete Products Installer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Precast Concrete Products Installer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

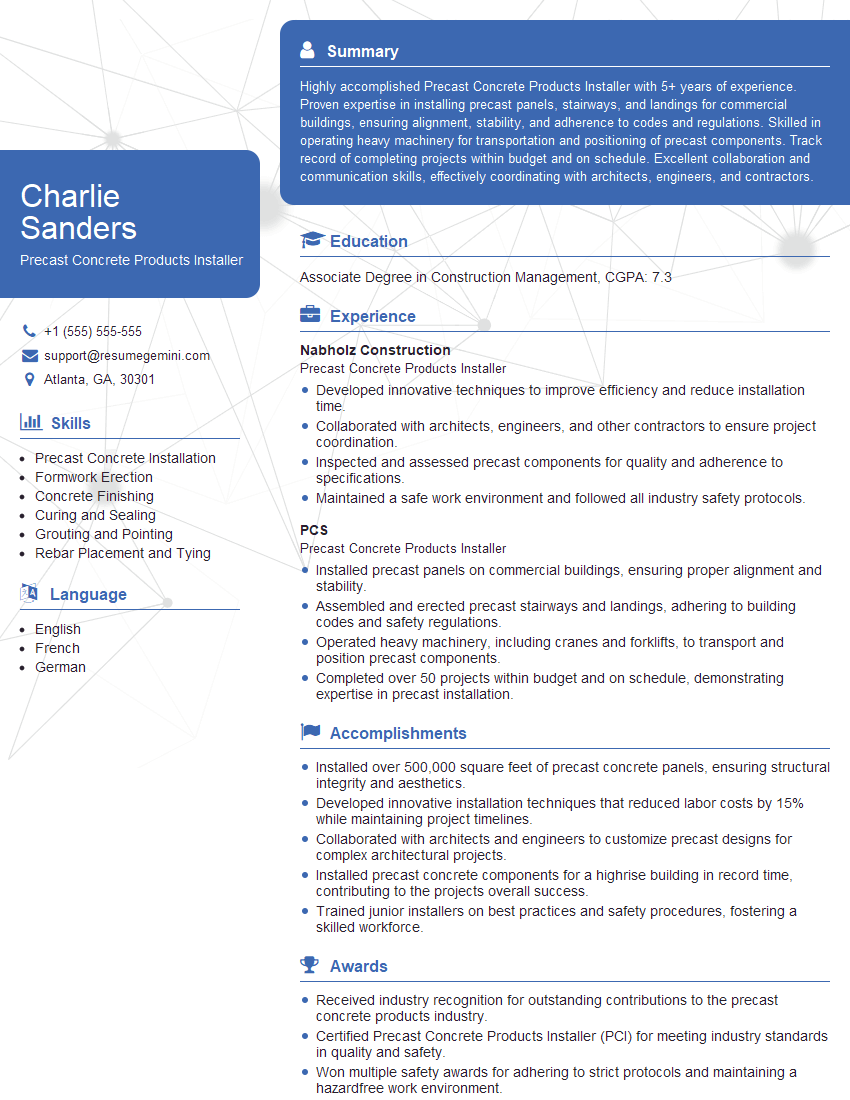

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precast Concrete Products Installer

1. What are the key considerations when installing precast concrete products?

There are numerous factors to take into account when installing precast concrete products, including:

- The weight and dimensions of the precast units

- The required accuracy and precision of the installation

- The environmental conditions during installation

- The type of foundation or substrate the units will be placed on

- The availability of equipment and manpower for the installation

2. What are the common types of precast concrete products and their applications?

- Architectural panels: Used for exterior cladding of buildings, offering aesthetic appeal and durability

- Bridge beams and girders: Support the weight of bridge decks and traffic, providing structural stability

- Utility vaults: Provide secure and accessible enclosures for electrical equipment and other utilities

- Retaining walls: Hold back soil and prevent erosion, used in landscaping and infrastructure projects

- Fence posts and columns: Provide support for fencing systems, ensuring perimeter security and privacy

3. Describe the process of preparing and installing precast concrete products.

The process typically involves the following steps:

- Site preparation: Grading the site, preparing the foundation, and establishing reference points

- Product delivery: Receiving and inspecting the precast units, ensuring they meet specifications

- Lifting and placement: Using cranes or other equipment to carefully lift and position the units

- Alignment and leveling: Adjusting the units to achieve the desired alignment and elevation

- Grouting and sealing: Filling joints and voids with grout or sealant to ensure structural integrity and water resistance

4. How do you ensure the quality and safety of precast concrete products during installation?

Quality and safety are paramount, and the following measures are taken:

- Material inspection: Verifying the strength, durability, and other properties of the precast units

- Proper handling and storage: Minimizing damage during transportation and storage

- Skilled installation techniques: Using appropriate methods and equipment to ensure proper placement and alignment

- Adherence to industry standards and codes: Complying with established guidelines for installation

- Regular maintenance and inspections: Monitoring the installed products to identify and address any issues early on

5. What are the challenges you have faced in installing precast concrete products and how did you overcome them?

Some challenges and their solutions include:

- Uneven surfaces: Using self-leveling grout or shims to compensate for irregularities

- Tight spaces: Utilizing specialized equipment and techniques for maneuvering units in constrained areas

- Weather conditions: Scheduling installations during favorable weather or taking precautions for extreme temperatures

- Complex designs: Collaborating with engineers and designers to develop innovative solutions for intricate installations

- Transportation logistics: Coordinating with suppliers and transporters to ensure timely and safe delivery of precast units

6. How do you stay updated with the latest industry standards and techniques for precast concrete installation?

I stay informed through the following methods:

- Continuing education: Attending workshops, seminars, and training programs

- Professional organizations: Participating in industry associations and connecting with other professionals

- Technical publications: Reading industry journals, manuals, and research papers

- Manufacturer updates: Subscribing to newsletters and attending product demonstrations

- On-site experience: Applying new knowledge and techniques in real-world installation projects

7. What are the safety hazards associated with precast concrete installation and how do you mitigate them?

Potential hazards and mitigation measures include:

- Heavy lifting: Using proper lifting equipment, following weight limits, and maintaining correct posture

- Falling objects: Wearing protective gear, securing units during transportation, and establishing exclusion zones

- Electrical hazards: Identifying and isolating electrical sources, using insulated tools, and grounding equipment

- Tripping and slipping: Wearing appropriate footwear, keeping work areas clean, and using anti-slip mats

- Noise and dust: Utilizing ear protection, respirators, and dust suppression systems

8. How do you collaborate with other tradespeople on precast concrete installation projects?

Collaboration is crucial, and I strive to:

- Communicate effectively: Regularly discuss project plans, schedules, and any concerns

- Respect other trades: Acknowledge their expertise and contribute to a positive working environment

- Coordinate activities: Plan sequencing of tasks to avoid conflicts and ensure efficient workflow

- Seek input: Consult with other tradespeople to gather their insights and feedback

- Resolve conflicts: Approach disagreements respectfully and work together to find solutions

9. Describe a complex or challenging precast concrete installation project you have worked on.

One notable project involved the installation of precast concrete panels for a high-rise building. The panels were intricate in design and required precise alignment. To ensure accuracy, we utilized laser leveling equipment and coordinated closely with the survey team. Despite the challenges, we successfully completed the installation, meeting the project’s demanding specifications.

10. What are your career goals and how do you see yourself contributing to our organization?

My career goal is to become a highly skilled and respected precast concrete installer. I am eager to contribute my expertise to your organization and support your commitment to excellence in precast concrete construction. I believe that my strong technical skills, dedication to safety, and ability to work effectively in a team environment will make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precast Concrete Products Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precast Concrete Products Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Precast Concrete Products Installers are responsible for installing precast concrete products, such as walls, beams, and columns, into buildings and other structures. They work closely with other construction workers, such as carpenters and masons, to ensure that the precast components are installed correctly and safely.

1. Installing Precast Concrete Products

The primary responsibility of a Precast Concrete Products Installer is to install precast concrete products, such as walls, beams, and columns, into buildings and other structures. This involves using cranes and other equipment to lift the precast components into place and securing them using bolts, screws, or other fasteners.

- Use cranes and other equipment to lift precast concrete products into place

- Secure precast concrete products using bolts, screws, or other fasteners

2. Inspecting Precast Concrete Products

Before installing precast concrete products, Installers must inspect them for any damage or defects. They also need to make sure that the products are the correct size and shape for the intended application.

- Inspect precast concrete products for any damage or defects

- Make sure that precast concrete products are the correct size and shape for the intended application

3. Maintaining Equipment

Precast Concrete Products Installers are responsible for maintaining the equipment they use, such as cranes and forklifts. This involves performing regular inspections and making sure that the equipment is in good working order.

- Perform regular inspections of equipment

- Make sure that equipment is in good working order

4. Following Safety Regulations

Precast Concrete Products Installers must follow all safety regulations when working on construction sites. This includes wearing proper safety gear, such as hard hats and safety glasses, and following all procedures for lifting and installing precast concrete products.

- Wear proper safety gear, such as hard hats and safety glasses

- Follow all procedures for lifting and installing precast concrete products

Interview Tips

To ace an interview for a Precast Concrete Products Installer position, it is important to be well-prepared and to have a good understanding of the job responsibilities. Here are a few tips to help you prepare for your interview:

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you learn more about their business and their culture. You can find information about the company on their website, in news articles, and on social media.

- Visit the company’s website

- Read news articles about the company

- Follow the company on social media

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions for Precast Concrete Products Installers include:

- Tell me about your experience installing precast concrete products.

- What are the most important safety regulations to follow when installing precast concrete products?

- How do you maintain the equipment you use to install precast concrete products?

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing any clothing that is too revealing or casual.

- Wear clean, pressed clothes

- Wear shoes that are closed-toe and polished

- Avoid wearing any clothing that is too revealing or casual

4. Arrive on Time

Punctuality is important, so be sure to arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the job.

- Plan your route to the interview in advance

- Leave early to give yourself plenty of time to find parking and get to the interview room

- If you are running late, call the interviewer to let them know

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Precast Concrete Products Installer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Precast Concrete Products Installer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.