Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Precision Assembly Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Precision Assembly Inspector so you can tailor your answers to impress potential employers.

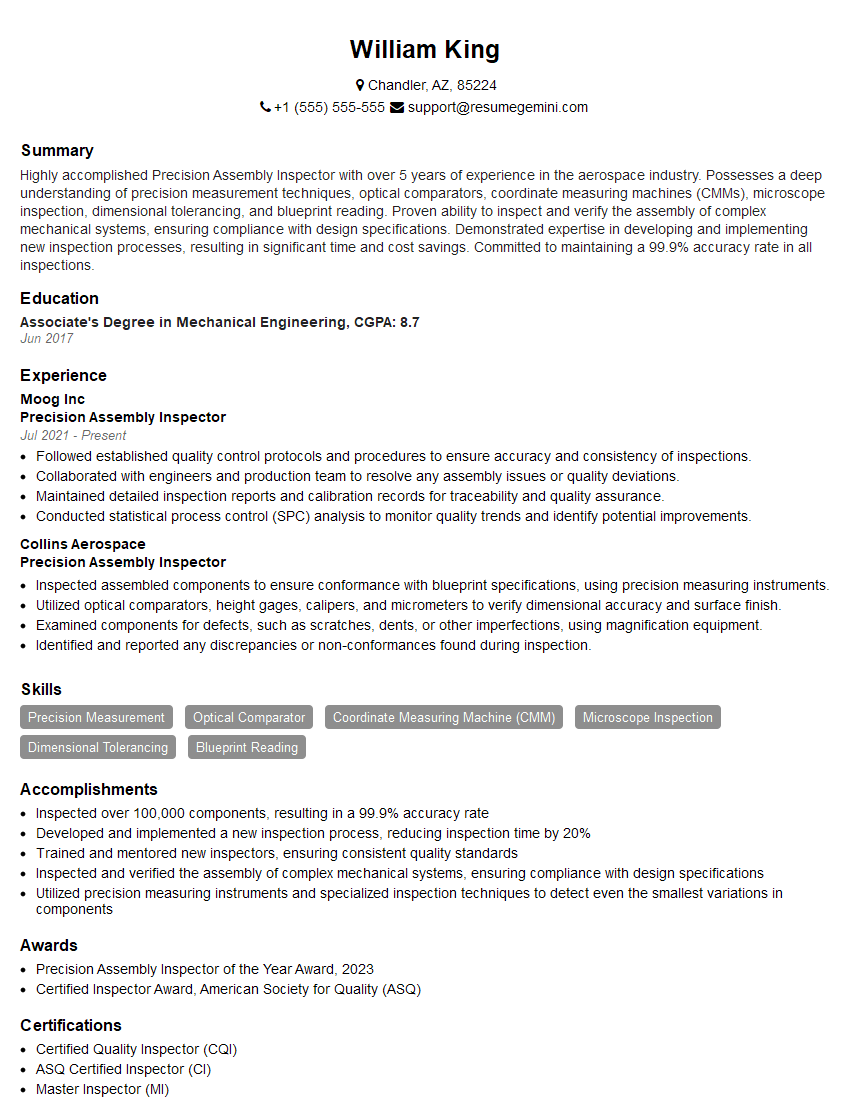

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precision Assembly Inspector

1. Explain the importance of following the assembly instructions precisely?

- Ensures accurate assembly and correct functioning of the product.

- Minimizes risks and errors, maintaining quality standards.

- Helps avoid rework or production delays due to incorrect assembly.

- Compliance with safety protocols and industry regulations.

2. How do you prioritize your tasks when multiple inspections are required simultaneously?

I prioritize tasks based on the following factors:

Urgency:

- Urgent inspections related to critical components or safety concerns.

- Deadlines and customer expectations.

Complexity:

- Inspections requiring specialized tools or extensive knowledge.

- Multi-step or complex assemblies that need careful attention.

Impact:

- Inspections that could affect the overall quality or functionality of the product.

- Inspections related to customer complaints or warranty issues.

3. Describe how you handle discrepancies or non-conformances during an inspection?

- Document and report the discrepancy in detail, including the affected parts, measurements, and observations.

- Communicate with the production or quality control team to determine the root cause and resolution plan.

- Escalate the issue to management if necessary, especially for serious discrepancies or compliance concerns.

- Follow up to ensure corrective actions are implemented and the issue is resolved effectively.

4. How do you ensure the accuracy of your inspections and minimize errors?

- Use calibrated and certified measuring tools and equipment regularly.

- Follow standardized inspection procedures and checklists.

- Perform double-checking or peer reviews to verify inspection results.

- Continuously improve inspection processes through training and feedback.

5. Tell me about a challenging inspection you encountered and how you resolved it?

In a recent inspection, I encountered a complex assembly with multiple subcomponents and tight tolerance requirements. The initial inspection revealed discrepancies, but the root cause was not immediately apparent. I took the following steps:

- Repeated the inspection carefully using different measuring tools.

- Consulted with the assembly team and engineers to understand the design specifications.

- Examined the parts under magnification to identify any inconsistencies or defects.

- Eventually, I discovered a slightly bent component that was causing the misalignment.

6. How do you stay updated with the latest inspection techniques and industry standards?

- Attend industry conferences, workshops, and training programs.

- Read trade publications, articles, and technical journals.

- Participate in professional organizations and forums.

- Collaborate with other inspectors and quality engineers to exchange knowledge.

7. Describe your experience with non-destructive testing (NDT) techniques?

I have experience with the following NDT techniques:

Liquid Penetrant Inspection:

- Detects surface cracks and discontinuities in metals.

Magnetic Particle Inspection:

- Detects surface and near-surface cracks in ferromagnetic materials.

Ultrasonic Testing:

- Detects internal defects and measures thickness using sound waves.

8. How do you handle situations where you are under pressure to meet deadlines and maintain a high level of quality?

- I prioritize tasks based on importance and urgency.

- I communicate my workload and any potential delays to my supervisor.

- I work efficiently and effectively without compromising accuracy.

- I seek assistance from colleagues or delegate tasks when necessary.

9. Explain the importance of attention to detail and meticulousness in your role as a Precision Assembly Inspector?

- Accurate assembly and functionality of products depend on precise inspections.

- Overlooked defects can lead to safety hazards or product failures.

- Meticulousness ensures compliance with specifications and quality standards.

- Attention to detail minimizes errors and improves overall production quality.

10. How do you stay motivated and engaged in your work as a Precision Assembly Inspector?

- I recognize the importance of my role in ensuring product quality and safety.

- I find satisfaction in contributing to the success of the company and its customers.

- I take pride in my accuracy and attention to detail.

- I am always eager to learn and improve my skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precision Assembly Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precision Assembly Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Precision Assembly Inspectors are responsible for ensuring that assembled products meet specific quality standards. Their primary duties include:

1. Inspecting Assemblies

Examining assembled products for defects, missing components, and proper assembly.

2. Utilizing Measurement Tools

Using precision measuring instruments, such as calipers, micrometers, and optical comparators, to verify dimensions, clearances, and tolerances.

3. Maintaining Quality Standards

Adhering to established quality control procedures and rejecting or approving products based on acceptance criteria.

4. Troubleshooting Assembly Issues

Investigating and identifying the source of assembly defects and recommending corrective actions.

5. Documenting Inspection Findings

Recording inspection results, identifying non-conformances, and maintaining accurate records.

Interview Tips

To ace the interview, candidates should:

1. Research the Company and Position

Understanding the company’s products, services, and the specific role requirements will help you tailor your answers to the interviewer’s expectations.

2. Practice Answering Common Interview Questions

Prepare for questions related to your precision assembly inspection experience, quality control knowledge, and problem-solving abilities.

Example: “Describe a time when you identified a critical defect during an inspection and resolved the issue.”

3. Highlight Measurement and Inspection Skills

Emphasize your proficiency in using precision measuring instruments and your attention to detail in identifying deviations from specifications.

Example: “In my previous role, I consistently achieved a 99% accuracy rate in measuring critical dimensions using a micrometer.”

4. Demonstrate Problem-Solving Capabilities

Provide specific examples of how you have analyzed assembly issues and implemented solutions to prevent defects.

Example: “I identified a recurring misalignment issue in a product assembly. By analyzing the process, I determined that a specific tool was not being used properly. After implementing a training program, the issue was resolved.”

5. Convey Strong Attention to Detail

Throughout the interview, emphasize your ability to work meticulously, identify subtle defects, and maintain accurate records.

Example: “In my quality control role, I meticulously inspected each product for even minor imperfections, ensuring that only the highest quality items were shipped to customers.”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Precision Assembly Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.