Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Precision Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

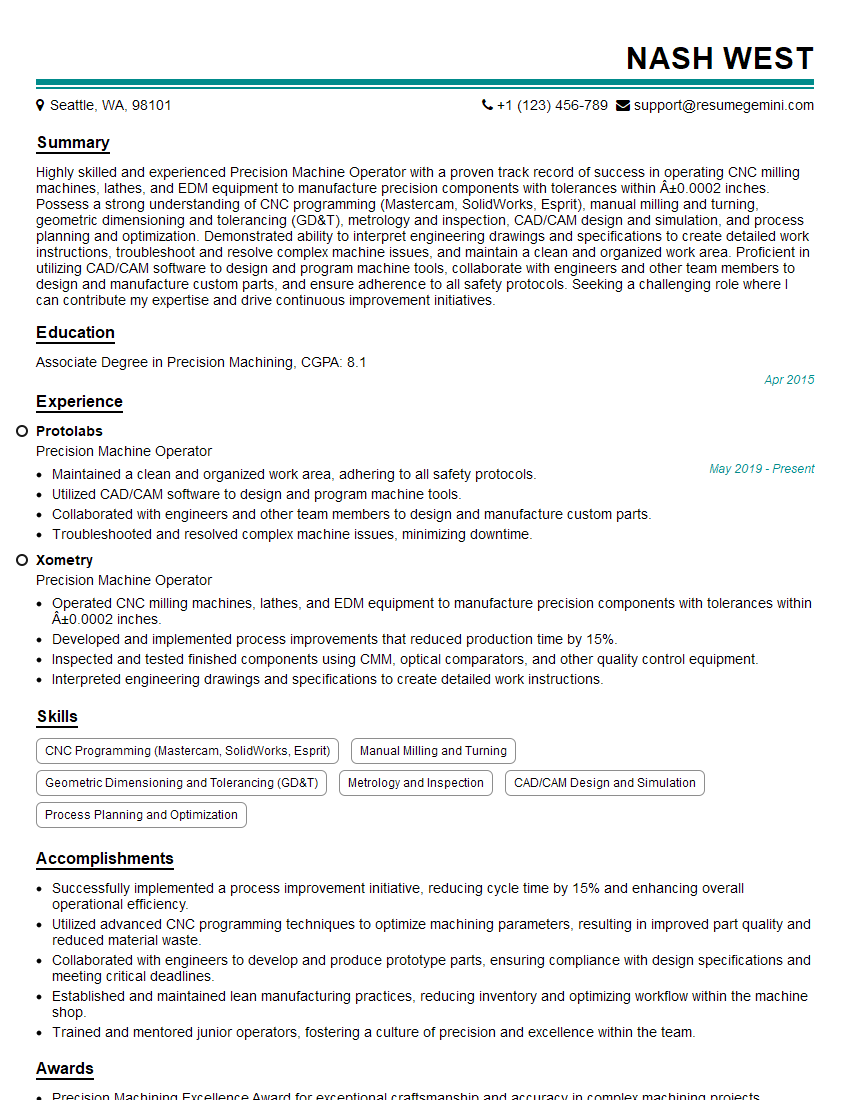

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precision Machine Operator

1. How would you approach a project that requires high levels of precision and accuracy?

Here’s how I would approach a project that demands high levels of precision and accuracy:

- Begin by thoroughly reviewing the specifications and drawings to ensure I fully understand the project’s requirements.

- Plan the sequence of operations carefully, considering the appropriate tools, techniques, and inspection methods.

- Set up the machine and tooling meticulously, ensuring that everything is properly calibrated and aligned.

- Follow the planned sequence of operations diligently, paying close attention to detail and taking frequent measurements to monitor accuracy.

- Continuously inspect the work throughout the process, using appropriate measuring instruments to verify dimensions and tolerances.

- Document the inspection results and any adjustments made to ensure traceability and maintain quality standards.

- Communicate regularly with the supervisor or engineer to provide updates and address any challenges encountered.

2. Describe the different types of precision measuring instruments you are familiar with and how to use them effectively.

Dimensional Measuring Instruments

- Calipers (Vernier, Dial, Digital): Measuring external and internal dimensions, depths, and steps.

- Micrometers (Outside, Inside, Depth): Precisely measuring small dimensions to thousandths of an inch or micrometers.

- Height Gauges: Determining the height of features relative to a reference surface.

Geometric Measuring Instruments

- Dial Indicators: Measuring small deviations from a reference surface or axis.

- Surface Plates: Establishing a flat and level reference for precision measurements.

- Angle Plates: Measuring and setting angles accurately.

Using Measuring Instruments Effectively

- Calibrating instruments regularly to ensure accuracy and reliability.

- Properly handling and storing instruments to prevent damage and maintain precision.

- Using the appropriate instrument for the task and measuring range.

- Taking multiple measurements and averaging the results to minimize errors.

- Interpreting measurements correctly and understanding the significance of tolerances.

3. How do you maintain and calibrate precision machine tools to ensure accuracy and efficiency?

Maintaining and calibrating precision machine tools is crucial to ensure accuracy and efficiency. Here’s how I approach this task:

- Follow the manufacturer’s recommended maintenance schedule for regular cleaning, lubrication, and adjustments.

- Inspect machines regularly for signs of wear, damage, or misalignment and address them promptly.

- Use precision measuring instruments to calibrate machines according to established standards and procedures.

- Adjust and fine-tune machine settings, such as backlash, spindle runout, and tool offsets, to optimize performance.

- Keep a maintenance log to document inspections, calibrations, and any repairs or adjustments performed.

4. Describe your experience with programming and operating CNC machines for precision machining tasks.

I have extensive experience programming and operating CNC machines for precision machining. My skills include:

- Proficient in CNC programming languages such as G-code and Fanuc.

- Developing and optimizing CNC programs for complex parts and geometries.

- Setting up and operating CNC machines, including tool selection, workholding, and cutting parameters.

- Monitoring CNC operations, making adjustments as needed to maintain precision.

- Working with CAM software to generate toolpaths and simulate machining processes.

5. How do you handle and interpret engineering drawings and technical specifications for precision machining?

Handling and interpreting engineering drawings and technical specifications for precision machining is a critical aspect of my job. I follow these steps:

- Review the drawings thoroughly, paying attention to dimensions, tolerances, surface finishes, and other requirements.

- Identify the critical dimensions and features that need special attention during machining.

- Understand the material properties and any specific requirements for machining the material.

- Determine the appropriate machining processes, tools, and cutting parameters based on the specifications.

- Use measuring instruments to verify dimensions and ensure compliance with the specifications.

6. Explain your approach to troubleshooting and resolving issues related to precision machining operations.

When encountering issues during precision machining operations, I follow a systematic approach to troubleshooting and resolution:

- Identify the symptoms and observe the behavior of the machine or process.

- Review the setup, programming, and cutting parameters to identify potential errors.

- Inspect the workpiece, tools, and fixtures for damage or wear.

- Consult with colleagues, supervisors, or technical documentation for guidance.

- Test different solutions and make adjustments until the issue is resolved.

- Document the troubleshooting process and the solution implemented for future reference.

7. How do you ensure the quality and consistency of precision machined parts?

Ensuring the quality and consistency of precision machined parts is paramount. I implement the following strategies:

- Follow established quality control procedures and standards throughout the machining process.

- Regularly inspect parts using appropriate measuring instruments and compare them to specifications.

- Maintain detailed records of inspections and measurements for traceability and documentation.

- Use statistical process control techniques to monitor and improve the quality of machining operations.

- Receive feedback from customers and make adjustments to processes as needed to meet or exceed expectations.

8. Describe your experience with working in a team environment on precision machining projects.

I have consistently worked in team environments on precision machining projects. My contributions include:

- Collaborating with engineers and designers to understand project requirements and translate them into machining plans.

- Working with other machinists to ensure smooth production and problem-solving.

- Sharing knowledge and expertise with team members to improve processes and enhance overall performance.

- Maintaining open communication and providing regular updates on progress and any challenges encountered.

9. How do you stay updated with the latest advancements and technologies in precision machining?

Staying updated with the latest advancements and technologies in precision machining is crucial. I engage in the following activities:

- Attend industry conferences, workshops, and training programs.

- Read technical journals, articles, and whitepapers related to precision machining.

- Network with other professionals in the field and exchange knowledge.

- Explore new technologies and equipment through research and vendor demonstrations.

- Seek opportunities to implement innovative techniques and improve existing processes.

10. Why are you interested in working as a Precision Machine Operator for our company?

I am eager to join your company as a Precision Machine Operator because:

- Your company’s reputation for producing high-quality and complex precision machined parts aligns with my skills and aspirations.

- The opportunity to contribute to cutting-edge projects and work with advanced machinery excites me.

- I am confident that my precision machining expertise and commitment to quality would make me a valuable asset to your team.

- I am eager to learn from experienced professionals and contribute to the company’s continued success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precision Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precision Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Precision Machine Operators utilize computer numerical controlled (CNC) machines to manufacture complex parts in a variety of industries.

1. Machine Operation and Setup

Operate and set up CNC machines, including milling machines, lathes, and grinders.

- Create and interpret CNC programs using CAD/CAM software.

- Set up and adjust machine parameters, such as speed, feed, and tool depth.

2. Quality Control and Inspection

Inspect and measure parts to ensure they meet specifications.

- Use precision measuring instruments, such as calipers, micrometers, and coordinate measuring machines (CMMs).

- Compare part dimensions to drawings and specifications.

3. Tooling and Maintenance

Select and install cutting tools and fixtures.

- Lubricate and clean machinery.

- Perform basic maintenance and repairs.

4. Production Planning and Monitoring

Plan and monitor production schedules.

- Identify and resolve production problems.

- Maintain production records.

Interview Tips

Acing an interview for a Precision Machine Operator position requires preparation and a strong understanding of the role’s responsibilities. Here are some tips to help you succeed:

1. Research the Position and Company

Before the interview, thoroughly research the specific Precision Machine Operator position and the company you’re applying to. This will demonstrate your interest and enthusiasm and allow you to tailor your answers accordingly.

- Visit the company’s website to learn about their products, services, and values.

- Search for news articles or industry reports about the company’s recent developments or achievements.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate during the actual interview:

- “Tell me about your experience in operating CNC machines?”

- “Describe your quality control and inspection process.”

- “How do you handle production problems?”

- “Why are you interested in this position with our company?”

3. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the Precision Machine Operator job description.

- Quantify your accomplishments whenever possible. For example, “I increased production efficiency by 15% by implementing a new CNC programming strategy.”

- Provide specific examples of your work, such as “I successfully machined complex parts to within 0.001 inch tolerances.”

4. Prepare Questions for the Interviewer

Asking informed questions at the end of the interview shows your interest and engagement.

- “What are the current production goals for the department?”

- “What opportunities are there for professional development within the company?”

- “Can you describe the company’s safety protocols and procedures?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Precision Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.