Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Precision Millwright position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

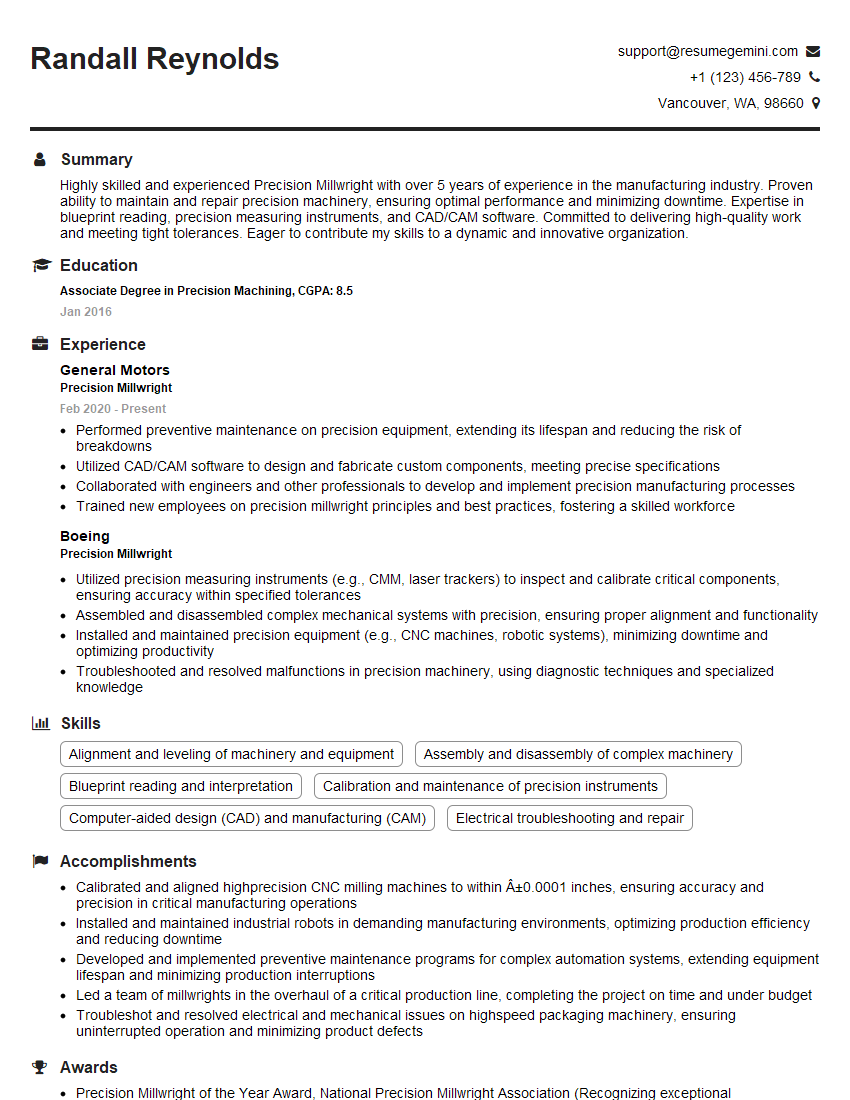

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precision Millwright

1. What are the key responsibilities of a Precision Millwright?

- Install, maintain, and repair precision machinery and equipment, ensuring accuracy and efficiency.

- Diagnose and troubleshoot mechanical and electrical problems to minimize downtime and ensure optimal performance.

- Read and interpret blueprints, technical drawings, and specifications to understand equipment requirements.

- Perform alignment and leveling procedures using precision instruments to ensure accuracy and precision.

- Collaborate with engineers, operators, and other technicians to ensure proper equipment installation and operation.

2. Describe your experience and expertise in using precision measuring tools and equipment.

Knowledge of Tools and Equipment

- Proficient in using precision measuring tools such as micrometers, calipers, dial indicators, height gauges, and laser levels.

- Expertise in handling and using machine tools, including lathes, milling machines, grinders, and CNC equipment.

- Skilled in using optical comparators, bore gauges, and other specialized precision measuring instruments.

Experience in Measurement Procedures

- Experienced in performing precision measurements to establish dimensions, tolerances, and alignment.

- Thorough understanding of measurement techniques, calibration procedures, and quality control standards.

- Proven ability to interpret measurement data and identify potential issues or deviations from specifications.

3. Explain your approach to ensuring the precision and accuracy of machinery and equipment.

- Follow established precision standards and best practices.

- Calibrate and maintain measuring tools and equipment regularly.

- Adhere to strict tolerance specifications and quality control procedures.

- Use precision alignment techniques and tools to ensure proper equipment installation and operation.

- Continuously monitor and evaluate equipment performance to identify potential issues and take corrective actions.

4. Describe your experience in troubleshooting and repairing complex machinery and equipment.

- Analyze equipment performance and identify potential causes of malfunctions or breakdowns.

- Use diagnostic tools and techniques to locate and isolate the source of problems.

- Disassemble, inspect, and repair components to restore equipment functionality.

- Perform adjustments and fine-tuning to optimize equipment performance.

- Document repair procedures and maintenance logs to ensure traceability and future reference.

5. How do you stay up-to-date with the latest advancements in precision manufacturing techniques and technologies?

- Attend industry conferences, workshops, and seminars.

- Read technical publications, journals, and articles.

- Participate in online forums and discussions.

- Collaborate with other professionals and experts in the field.

- Seek opportunities for professional development and training.

6. Describe your experience in working with engineers and other technical professionals.

- Effectively communicate technical information and collaborate on project requirements.

- Translate engineering designs and specifications into practical solutions.

- Provide technical support and expertise to assist engineers in equipment selection and design.

- Work closely with operators and maintenance personnel to identify and resolve issues.

- Contribute to continuous improvement initiatives and process optimizations.

7. Explain your understanding of the importance of safety in the precision manufacturing environment.

- Adhere to all safety regulations and protocols.

- Identify and assess potential hazards in the workplace.

- Use appropriate personal protective equipment (PPE) and follow safe work practices.

- Report unsafe conditions or practices to supervisors.

- Participate in safety training and drills to enhance knowledge and skills.

8. Describe a situation where you successfully resolved a complex technical issue in a precision manufacturing environment.

- Identify the problem and analyze its potential causes.

- Develop and implement a troubleshooting plan.

- Use precision measuring tools and diagnostic techniques to identify the root cause.

- Repair or replace defective components and adjust equipment to restore functionality.

- Evaluate the solution and make necessary adjustments to ensure optimal performance.

9. What are your strengths and weaknesses as a Precision Millwright?

- Exceptional attention to detail and accuracy.

- Proficient in using precision measuring tools and equipment.

- Strong troubleshooting and problem-solving abilities.

- Excellent communication and interpersonal skills.

- Limited experience with certain specialized precision manufacturing technologies.

- Working independently for extended periods can sometimes be challenging.

Strengths:

Weaknesses:

10. Why are you interested in working as a Precision Millwright in our company?

- Your company has a reputation for excellence in the industry.

- I am eager to contribute my skills and experience to your team.

- I am passionate about precision manufacturing and committed to delivering high-quality results.

- I am confident that I can make a significant contribution to your company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precision Millwright.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precision Millwright‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Precision Millwrights are responsible for the installation, maintenance, and repair of precision machinery and equipment in a variety of industries. Their primary goal is to ensure that all machinery operates smoothly and efficiently, with minimal downtime.

1. Equipment Installation and Maintenance

Install, maintain, and repair precision machinery and equipment according to manufacturer specifications and industry standards.

- Read and interpret blueprints, schematics, and technical manuals.

- Use hand and power tools to assemble, disassemble, and adjust machinery.

- Perform preventive maintenance tasks, such as lubrication, cleaning, and inspection.

- Troubleshoot and repair equipment malfunctions.

- Calibrate and test equipment to ensure accuracy and performance.

2. Mechanical Repair and Fabrication

Perform mechanical repairs and fabrications to maintain and improve equipment functionality.

- Weld, braze, and solder metal components.

- Machine parts using lathes, mills, and other machine tools.

- Fabricate and install custom parts and fixtures.

3. Electrical and Hydraulic Maintenance

Maintain and repair electrical and hydraulic systems associated with machinery.

- Troubleshoot and repair electrical circuits and components.

- Maintain and repair hydraulic systems, including pumps, valves, and cylinders.

- Install and maintain electrical and hydraulic controls.

4. Safety and Compliance

Ensure a safe work environment and comply with all safety regulations and procedures.

- Follow proper lockout/tagout procedures.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

- Report any safety hazards or concerns to supervisors.

Interview Tips

Interviewing for a Precision Millwright position can be a competitive process. Here are some tips to help you ace the interview and increase your chances of landing the job.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Precision Millwright position you are applying for. This will help you understand the company’s culture, values, and the specific skills and experience they are looking for in a candidate.

- Visit the company’s website.

- Read industry publications and news articles.

- Connect with current or former employees on LinkedIn.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview.

- Review the job description and identify key skills and experience.

- Prepare examples of your work experience that demonstrate these skills.

- Practice answering questions about your experience, qualifications, and goals.

3. Highlight Your Precision and Attention to Detail

Precision Millwrights must have a high level of precision and attention to detail. In your interview, make sure to highlight your ability to work accurately and meet tight tolerances.

- Describe your experience working with precision equipment.

- Provide examples of projects where you achieved exceptional accuracy.

- Emphasize your commitment to quality and your attention to detail.

4. Show Your Problem-Solving Skills

Precision Millwrights often encounter unexpected problems on the job. In your interview, demonstrate your problem-solving skills by describing how you have handled challenges in the past.

- Describe a time when you had to troubleshoot and repair a complex piece of equipment.

- Explain how you approached the problem, identified the root cause, and developed a solution.

- Emphasize your ability to think critically and find creative solutions.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Precision Millwright, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Precision Millwright positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.