Are you gearing up for an interview for a Precision Mold and Pattern Caster, Except Nonferrous Metal position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Precision Mold and Pattern Caster, Except Nonferrous Metal and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

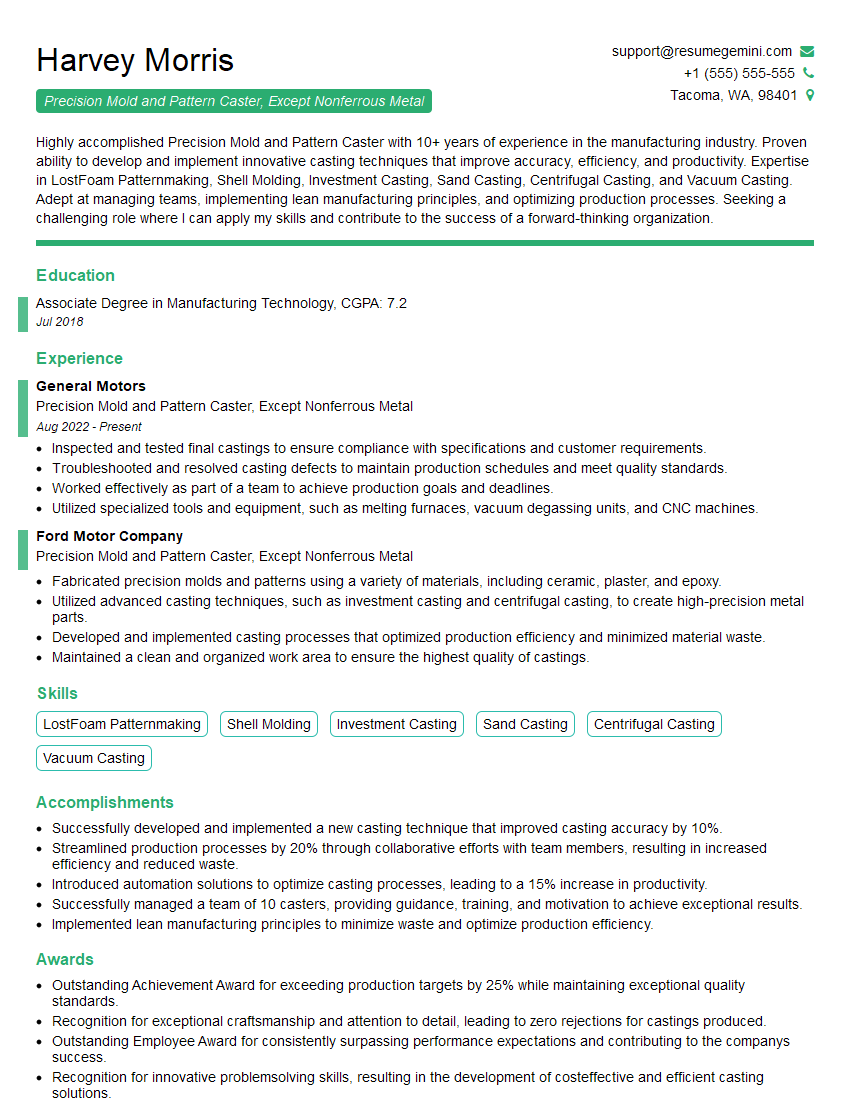

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Precision Mold and Pattern Caster, Except Nonferrous Metal

1. Describe the core principles of precision mold and pattern casting, excluding nonferrous metals?

Precision mold and pattern casting involves creating intricate metal components with precise dimensions and surface finishes. Core principles include:

- Patternmaking: Crafting accurate patterns that define the desired shape and dimensions of the casting.

- Molding: Creating a mold cavity that replicates the pattern using various molding materials.

- Pouring: Filling the mold cavity with molten metal and allowing it to solidify.

- Post-casting operations: Removing the casting from the mold, cleaning it, and performing any necessary finishing processes.

2. Elaborate on the types of materials used in precision mold and pattern casting, and their respective strengths and weaknesses.

Molding Materials

- Sand: Inexpensive, but requires multiple binders and can exhibit dimensional limitations.

- Ceramic: Produces high-precision castings but is more expensive and brittle.

- Metal: Durable, but difficult to remove from the casting and can be costly.

Pattern Materials

- Wood: Inexpensive and easy to machine, but can warp and deteriorate over time.

- Metal: Durable and dimensionally stable, but more expensive and labor-intensive to produce.

- 3D Printed Plastics: Rapid prototyping and customization, but may have limited strength and durability.

3. Explain the key variables that influence the quality of precision mold and pattern castings.

- Pattern accuracy and surface finish

- Mold material selection and preparation

- Metal composition and pouring temperature

- Cooling rate and post-casting treatments

- Operator skill and experience

4. Describe the common defects that can occur in precision mold and pattern castings, and suggest measures to prevent them.

- Shrinkage: Use risers and chills to control cooling and prevent voids.

- Porosity: Ensure proper degassing of molten metal, avoid contamination, and use vacuum casting techniques.

- Cold shuts: Pour molten metal at the correct temperature, avoid interruptions during pouring, and use proper gating and risering.

- Hot tears: Control cooling rates, reduce stresses in the mold, and avoid excessive metal temperatures.

5. Discuss the latest advancements in precision mold and pattern casting technology.

- 3D printing of patterns: Rapid prototyping, complex geometries, and reduced lead times.

- Investment casting: High-precision castings with intricate details and excellent surface finishes.

- Rapid tooling: Faster production of high-quality molds through advanced machining and additive manufacturing techniques.

6. Explain the importance of quality control in precision mold and pattern casting.

- Ensures product quality and reliability

- Reduces scrap and rework, minimizing production costs

- Maintains customer satisfaction and reputation

- Complies with industry standards and regulations

7. Describe the typical work environment for a Precision Mold and Pattern Caster, Except Nonferrous Metal.

- Foundries or metalworking shops

- May involve exposure to molten metal, fumes, dust, and noise

- Physical demands such as lifting heavy materials and standing for extended periods

- Collaboration with engineers and other production personnel

8. What are the key skills and qualifications required to excel as a Precision Mold and Pattern Caster, Except Nonferrous Metal?

- Thorough understanding of precision casting principles and materials

- Excellent patternmaking and moldmaking skills

- Proficiency in metalworking and casting equipment

- Attention to detail and quality consciousness

- Ability to work independently and as part of a team

9. Describe your experience in troubleshooting casting defects and implementing corrective actions.

Provide specific examples of defects encountered, the root causes identified, and the solutions implemented to prevent recurrence.

10. How do you stay updated with the latest advancements in precision mold and pattern casting technology?

- Attend conferences and workshops

- Read industry publications and technical journals

- Engage in online forums and networking events

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Precision Mold and Pattern Caster, Except Nonferrous Metal.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Precision Mold and Pattern Caster, Except Nonferrous Metal‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Precision Mold and Pattern Casters create molds and patterns used in the production of metal castings. They use a variety of materials in their work, including wax, plastic, metal, and wood.

1. Create Molds and Patterns

This is the primary responsibility of a Precision Mold and Pattern Caster. They create molds and patterns that are used to cast metal objects. The molds and patterns must be accurate and precise, as they will be used to create the final product.

- Analyze blueprints and specifications to determine the dimensions and shape of the mold or pattern.

- Select the appropriate materials and tools for the job.

- Create the mold or pattern using a variety of techniques, such as carving, casting, or molding.

- Inspect the mold or pattern to ensure that it meets the required specifications.

2. Maintain Molds and Patterns

Precision Mold and Pattern Casters are also responsible for maintaining the molds and patterns they create. This includes cleaning, repairing, and storing the molds and patterns.

- Clean the molds and patterns after each use.

- Repair any damage to the molds and patterns.

- Store the molds and patterns in a safe and dry place.

3. Other Responsibilities

In addition to the above, Precision Mold and Pattern Casters may also be responsible for the following tasks:

- Operate casting machines.

- Inspect castings for defects.

- Assist in the production of metal castings.

- Work with other members of the production team.

Interview Tips

1. Research the Company and Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on its website, social media pages, and Glassdoor.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience, so be prepared to talk about them in detail. Highlight the skills and experience that are most relevant to the position you are applying for. You can also mention any projects or accomplishments that you are particularly proud of.

4. Be Enthusiastic and Positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to convey your interest in the job and the company. Let the interviewer know that you are excited about the opportunity to work for them.

5. Follow Up After the Interview

After the interview, be sure to send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and to thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Precision Mold and Pattern Caster, Except Nonferrous Metal interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!