Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Preform Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

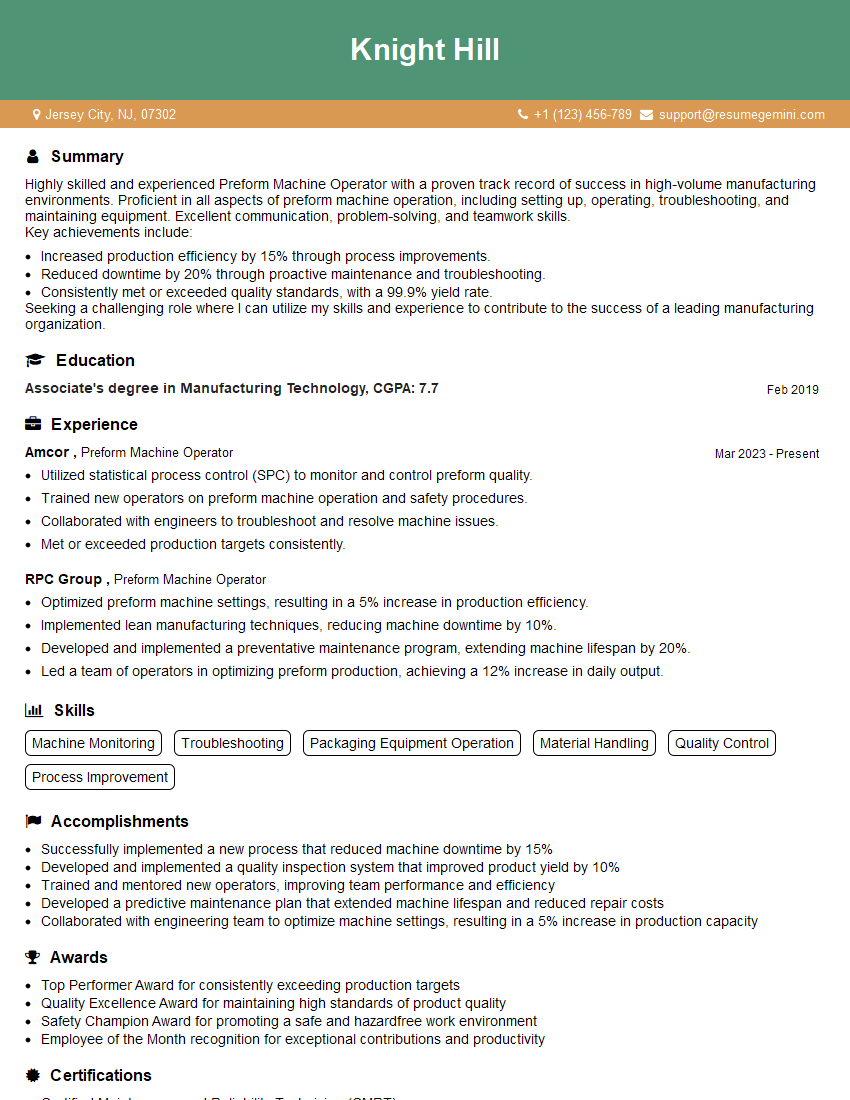

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Preform Machine Operator

1. Describe the steps involved in setting up a preform machine?

- Inspect the preform machine and make sure it is clean and free of debris.

- Install the correct preform mold and adjust the settings.

- Load the preform material into the hopper.

- Start the machine and adjust the speed and temperature settings.

- Monitor the machine and make sure the preforms are being produced correctly.

2. What are the different types of preform machines and their uses?

Injection molding machines

- Used to produce preforms for plastic bottles and containers.

- Can produce a wide variety of preform shapes and sizes.

- High production rates.

Extrusion blow molding machines

- Used to produce preforms for plastic bottles and containers.

- Can produce preforms with complex shapes.

- Lower production rates than injection molding machines.

Compression molding machines

- Used to produce preforms for plastic caps and closures.

- Can produce preforms with complex shapes.

- Low production rates.

3. What are the safety precautions that must be followed when operating a preform machine?

- Wear appropriate safety gear, including gloves, safety glasses, and ear protection.

- Keep the work area clean and free of debris.

- Never operate the machine when it is not properly guarded.

- Do not attempt to clear jams or make adjustments to the machine while it is running.

- Report any malfunctions or safety concerns to your supervisor immediately.

4. How do you troubleshoot common problems with a preform machine?

- If the preforms are not being produced correctly, check the mold settings and make sure the machine is running at the correct speed and temperature.

- If the machine is jamming, clear the jam and inspect the preform mold for any damage.

- If the machine is leaking, check the seals and gaskets for any damage.

- If the machine is making a loud noise, check the bearings and gears for any damage.

- If the machine is not starting, check the electrical connections and make sure the power is turned on.

5. What are the maintenance procedures for a preform machine?

- Clean the machine regularly to remove any debris.

- Inspect the machine regularly for any damage.

- Lubricate the machine regularly according to the manufacturer’s instructions.

- Calibrate the machine regularly to ensure that it is running at the correct speed and temperature.

- Follow the manufacturer’s instructions for any other maintenance procedures.

6. What are the different types of preform materials and their properties?

- PET

- High strength and clarity

- Good chemical resistance

- Recyclable

- HDPE

- High strength and stiffness

- Good chemical resistance

- Not recyclable

- LDPE

- Low strength and stiffness

- Good flexibility

- Recyclable

- PP

- High strength and stiffness

- Good chemical resistance

- Recyclable

7. How do you ensure that the preforms meet the required quality standards?

- Inspect the preforms regularly for any defects.

- Use a quality control chart to track the preform quality.

- Make adjustments to the machine or the process as needed to maintain the desired quality level.

8. What are the different types of preform defects and how do you prevent them?

- Short shots

- Caused by insufficient material in the mold

- Can be prevented by increasing the injection pressure or the material temperature

- Flash

- Caused by material leaking out of the mold

- Can be prevented by increasing the mold clamping force or adjusting the mold settings

- Warping

- Caused by uneven cooling of the preform

- Can be prevented by adjusting the cooling system or the mold temperature

- Bubbles

- Caused by air trapped in the material

- Can be prevented by degassing the material or adjusting the injection pressure

9. What is the importance of preform quality in the blow molding process?

- Preform quality affects the quality of the blow molded product.

- Defective preforms can cause problems in the blow molding process, such as jams and broken bottles.

- Ensuring preform quality is essential for producing high-quality blow molded products.

10. What is your experience with preform machine operation?

- I have 5 years of experience operating preform machines in a plastic bottle manufacturing plant.

- I am familiar with all aspects of preform machine operation, including setup, maintenance, and troubleshooting.

- I have a strong understanding of preform quality and the importance of meeting quality standards.

- I am a highly motivated and reliable employee with a proven track record of success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Preform Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Preform Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Preform Machine Operators play a crucial role in the manufacturing process, ensuring the efficient production of high-quality plastic preforms used in various industries.

1. Machine Operation and Maintenance

Operate preform injection molding machines, monitoring and adjusting machine parameters such as temperature, pressure, and cycle times.

- Perform routine maintenance and troubleshooting to ensure optimal machine performance.

- Calibrate and set up molds to produce preforms with precise dimensions and quality.

2. Preform Inspection and Quality Control

Inspect preforms to ensure they meet quality standards, checking for defects, dimensions, and surface finish.

- Use measuring tools and gauges to verify the accuracy and consistency of preforms.

- Report any deviations from specifications and work with supervisors to resolve quality issues.

3. Process Monitoring and Optimization

Monitor production processes, identifying and addressing potential bottlenecks or inefficiencies.

- Make adjustments to machine settings and processes to improve cycle times and reduce waste.

- Analyze production data to identify trends and suggest improvements to enhance productivity.

4. Safety and Compliance

Follow established safety protocols, including wearing appropriate personal protective equipment.

- Maintain a clean and organized work area to prevent accidents and ensure product quality.

- Adhere to company policies and regulations regarding manufacturing practices and environmental compliance.

Interview Preparation Tips

To ace the job interview, it is essential to prepare thoroughly and present yourself as a confident and capable candidate. Here are some key tips to help you succeed:

1. Research the Company and Position

Before the interview, thoroughly research the company, its industry, and the specific role you are applying for. This will demonstrate your interest and eagerness to learn more about the opportunity.

- Visit the company website to gather information about its mission, values, and products/services.

- Read industry news and articles to understand the company’s competitors, market trends, and technological advancements.

2. Practice Your Answers and Prepare Questions

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Rehearse your responses to highlight your skills, experience, and qualifications that align with the job requirements.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Prepare thoughtful questions to ask the interviewer, showing your engagement and interest in the company and position.

3. Dress Professionally and Arrive on Time

Dress appropriately for the interview, making a positive first impression. Arrive punctually to demonstrate your respect for the interviewer’s time and professionalism.

- Wear clean, pressed business attire that aligns with the company’s culture and industry standards.

- Plan your route ahead of time to avoid delays and arrive at the interview location with ample time to spare.

4. Be Enthusiastic and Confident

Approach the interview with enthusiasm and confidence in your abilities. Maintain eye contact, speak clearly, and actively listen to the interviewer’s questions and responses.

- Convey your passion for the manufacturing industry and your desire to contribute to the company’s success.

- Highlight your technical skills, problem-solving abilities, and commitment to quality and safety.

5. Follow Up and Express Gratitude

After the interview, send a thank-you email to the interviewer expressing your appreciation for their time and consideration. Reiterate your interest in the position and briefly mention any key points you discussed during the interview.

- Send the thank-you email within 24 hours of the interview, while the conversation is still fresh in the interviewer’s mind.

- Use the opportunity to reiterate your qualifications and highlight any additional information that could strengthen your candidacy.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Preform Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.