Feeling lost in a sea of interview questions? Landed that dream interview for Preforms Laminator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Preforms Laminator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

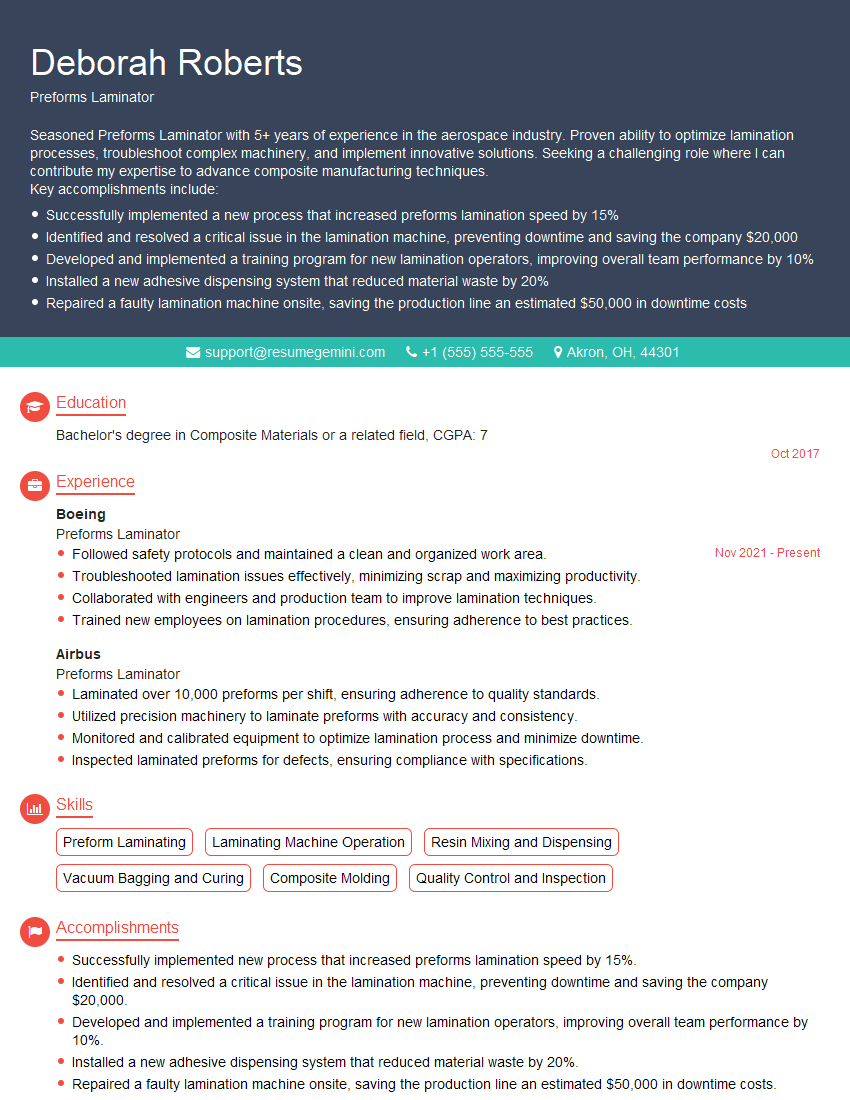

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Preforms Laminator

1. What are the key steps involved in the preform lamination process?

The key steps involved in the preform lamination process include:

- Selecting the appropriate preforms and materials

- Preparing the preforms and materials for lamination

- Applying the adhesive or resin to the preforms

- Laminating the preforms together under pressure and heat

- Post-curing the laminated preform

2. How do you ensure the quality of the laminated preforms?

Raw material inspection

- Inspect the preforms and materials for defects

- Verify the dimensions and specifications of the preforms

Process control

- Control the temperature, pressure, and time during lamination

- Monitor the adhesion strength and other properties of the laminated preforms

Finished product inspection

- Inspect the laminated preforms for defects

- Test the performance of the laminated preforms

3. What are the common defects that can occur during the preform lamination process?

The common defects that can occur during the preform lamination process include:

- Air bubbles

- Delamination

- Fiber misalignment

- Resin starvation

- Void

4. How do you troubleshoot and resolve problems during the preform lamination process?

To troubleshoot and resolve problems during the preform lamination process, you can:

- Identify the source of the problem

- Determine the root cause of the problem

- Develop and implement a solution to the problem

- Verify the effectiveness of the solution

5. What are the safety precautions that need to be observed during the preform lamination process?

The safety precautions that need to be observed during the preform lamination process include:

- Wearing appropriate personal protective equipment

- Working in a well-ventilated area

- Handling chemicals safely

- Following proper operating procedures

- Maintaining a clean and organized work area

6. What are the different types of preform laminating machines?

The different types of preform laminating machines include:

- Flat press laminating machines

- Curved press laminating machines

- Continuous laminating machines

- Automated laminating machines

7. How do you select the appropriate preform laminating machine for a specific application?

To select the appropriate preform laminating machine for a specific application, you need to consider:

- The size and shape of the preforms

- The type of material used for the preforms

- The production rate required

- The budget available

8. What are the key maintenance tasks for a preform laminating machine?

The key maintenance tasks for a preform laminating machine include:

- Cleaning the machine regularly

- Lubricating the moving parts

- Inspecting the machine for wear and tear

- Calibrating the machine regularly

- Performing preventive maintenance tasks as per the manufacturer’s recommendations

9. What are the advantages of using preform laminating over other composite manufacturing methods?

The advantages of using preform laminating over other composite manufacturing methods include:

- Improved quality and consistency

- Higher production rates

- Reduced material waste

- Lower labor costs

- Greater design flexibility

10. What are the latest developments in preform laminating technology?

The latest developments in preform laminating technology include:

- The development of new materials and resins

- The development of new laminating machines

- The development of new process technologies

- The use of automation and robotics

- The adoption of lean manufacturing principles

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Preforms Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Preforms Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Preforms Laminators are responsible for operating and maintaining preform laminating machines, which produce preforms for the manufacturing of plastic bottles. Key job responsibilities include:

1. Machine Operation

Loading and unloading preform molds into the laminating machine

- Operating the laminating machine to produce preforms according to specified parameters

- Monitoring the machine’s operation and making necessary adjustments

2. Quality Control

Inspecting preforms for defects and ensuring they meet quality standards

- Performing dimensional measurements and weight checks

- Conducting visual inspections for scratches, cracks, or other imperfections

3. Maintenance

Performing routine maintenance tasks on the laminating machine

- Cleaning and lubricating the machine’s components

- Replacing worn or damaged parts

4. Safety

Following all safety procedures and wearing appropriate personal protective equipment

- Ensuring the work area is clean and free of hazards

- Reporting any safety concerns or incidents immediately

Interview Tips

Preparing for an interview for a Preforms Laminator position requires a combination of technical knowledge and a solid understanding of the industry. Here are some tips to help candidates ace their interview:

1. Research the Company

Before the interview, candidates should thoroughly research the company, its products, and its industry. This will help them understand the company’s culture and values, as well as its specific needs and expectations for the Preforms Laminator role.

2. Practice Answering Common Interview Questions

There are several common interview questions that candidates can prepare for. Some of the most frequent questions include:

- Tell me about your experience in preform lamination.

- What are the most important quality control checks you perform?

- How do you ensure the safety of yourself and others when working with laminating machines?

3. Highlight Transferable Skills

While specific experience in preform lamination is preferred, candidates can also highlight transferable skills that are relevant to the role. These skills may include:

- Experience with operating and maintaining manufacturing equipment

- Knowledge of quality control procedures

- A strong work ethic and attention to detail

4. Be Enthusiastic and Professional

During the interview, candidates should demonstrate their enthusiasm for the role and the industry. They should also be professional and respectful throughout the interview process. A positive attitude and a willingness to learn can make a great impression on the interviewer.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Preforms Laminator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.