Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Prepleater position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

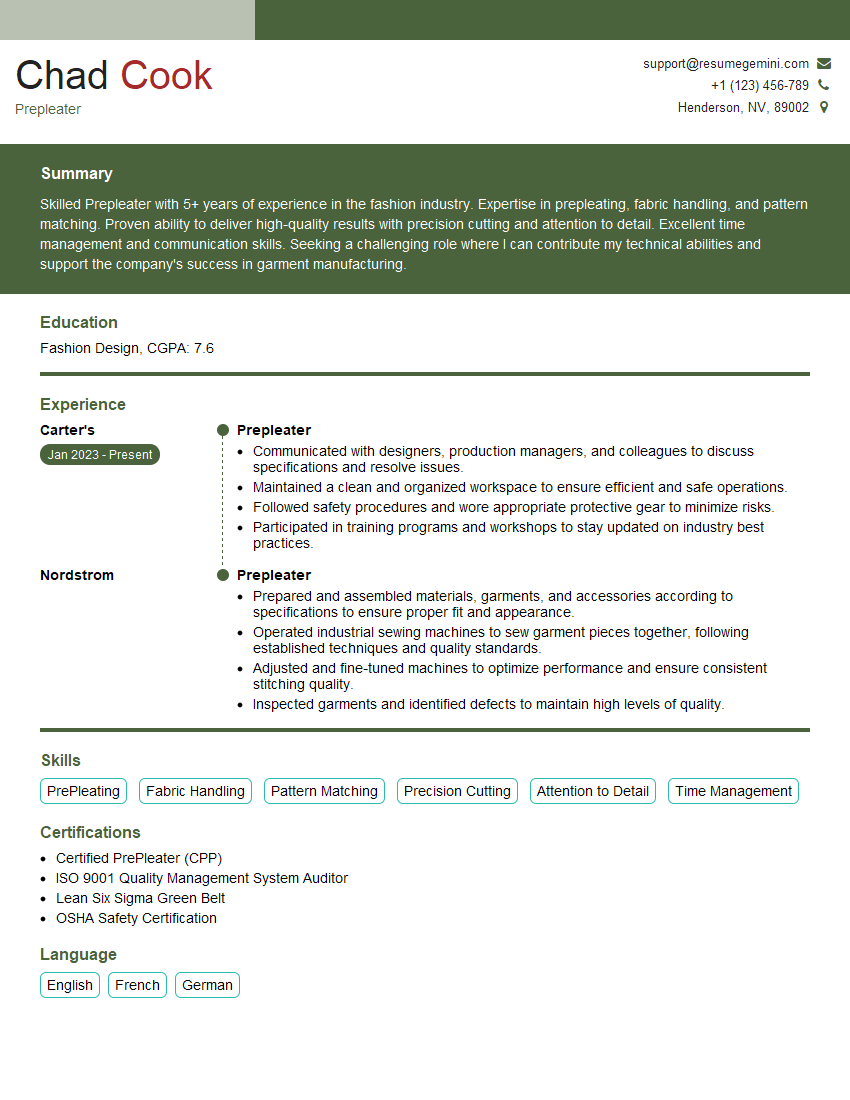

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Prepleater

1. Describe the pre-pleating process?

The pre-pleating process involves several steps to prepare fabric for pleating:

- Fabric selection: Choosing the appropriate fabric with the desired drape and pleatability.

- Fabric preparation: Inspecting and preparing the fabric by removing any imperfections or dirt.

- Marking and measuring: Accurately marking and measuring the fabric to determine the pleat size, spacing, and overall design.

- Stitching: Using specialized stitching machines to create small, precise stitches along the marked lines, forming the pleats.

- Heat setting: Exposing the stitched fabric to heat to set the pleats in place and prevent them from unraveling.

2. What are the different types of pleating machines?

Manual pleating machines

- Hand-crank pleaters: Operated by manually turning a crank to feed the fabric through pleating rollers.

- Foot-powered pleaters: Using a foot pedal to power the pleating process, allowing for faster and more consistent results.

Automatic pleating machines

- Programmable pleaters: Equipped with computer-controlled systems that allow for precise and customizable pleating patterns.

- Ultrasonic pleaters: Utilizing ultrasonic technology to fuse the fabric layers together, creating pleats without the need for stitching.

- Laser pleaters: Employing lasers to cut and seal the fabric, creating intricate and precise pleats with minimal heat damage.

3. How do you ensure the quality of pre-pleated fabric?

Ensuring the quality of pre-pleated fabric involves several key steps:

- Fabric inspection: Inspecting the fabric for any defects, unevenness, or damage before pleating.

- Accurate marking and measuring: Using precise tools and techniques to ensure uniform pleat size and spacing.

- Proper stitching: Utilizing well-maintained stitching machines and high-quality threads to create secure and consistent pleats.

- Heat setting optimization: Determining the optimal temperature and duration of heat treatment to achieve durable and long-lasting pleats.

- Post-pleating inspection: Conducting a thorough inspection of the finished fabric to identify any imperfections or irregularities.

4. What are the common challenges in pre-pleating, and how do you overcome them?

Common challenges in pre-pleating include:

- Fabric shrinkage: Overcoming fabric shrinkage during heat setting by using pre-shrunk fabrics or adjusting heat treatment accordingly.

- Uneven pleats: Ensuring even pleats by using precise marking and measuring techniques, as well as proper machine calibration.

- Broken pleats: Preventing broken pleats by using the correct stitch type, tension, and thread quality, as well as avoiding excessive handling of the fabric.

- Heat damage: Minimizing heat damage by optimizing heat setting parameters and using heat-resistant fabrics.

5. How do you stay updated with the latest pre-pleating techniques and technologies?

To stay updated with the latest pre-pleating techniques and technologies, I engage in various activities such as:

- Industry conferences and workshops: Attending industry events to learn about new advancements and best practices.

- Trade publications and online resources: Subscribing to industry magazines, websites, and forums to stay informed about emerging technologies and trends.

- Networking with industry professionals: Connecting with other pre-pleaters, manufacturers, and designers to exchange knowledge and experiences.

- Research and experimentation: Conducting my own research and experimenting with different techniques to push the boundaries of pre-pleating.

6. Describe your experience in working with different fabrics for pre-pleating.

I have extensive experience in working with a wide range of fabrics for pre-pleating, including:

- Natural fibers: Cotton, linen, silk, and wool.

- Synthetic fibers: Polyester, nylon, and rayon.

- Blends: Combinations of natural and synthetic fibers.

- Specialty fabrics: Organza, chiffon, and velvet.

I understand the unique properties and pleating characteristics of each fabric, enabling me to optimize the pre-pleating process to achieve the desired results.

7. What are the current trends in pre-pleating?

Current trends in pre-pleating include:

- Three-dimensional pleating: Creating pleats that add depth and texture to fabrics.

- Laser pleating: Utilizing lasers to create precise and intricate pleat patterns.

- Pleated embellishments: Incorporating pleats into fabric embellishments, such as ruffles, collars, and cuffs.

- Sustainable pleating: Using eco-friendly fabrics and processes to minimize the environmental impact of pre-pleating.

- Digital printing on pleated fabrics: Printing designs and patterns on pleated fabrics to create unique and eye-catching effects.

8. How do you ensure the colorfastness of pre-pleated fabrics?

To ensure the colorfastness of pre-pleated fabrics, I follow these steps:

- Fabric selection: Choosing fabrics with high colorfastness ratings to minimize fading or bleeding.

- Pre-washing: Washing the fabric before pleating to remove any loose dyes or impurities.

- Proper heat setting: Using the appropriate temperature and duration of heat treatment to avoid color changes.

- Colorfastness testing: Conducting colorfastness tests on pre-pleated fabrics to ensure they meet industry standards.

9. How do you handle bulk pre-pleating orders?

To handle bulk pre-pleating orders efficiently, I employ the following strategies:

- Production planning: Optimizing the production schedule to ensure timely delivery of orders.

- Equipment maintenance: Keeping pleating machines well-maintained to maximize productivity and minimize downtime.

- Team coordination: Collaborating with a skilled team to ensure smooth operation and quality control.

- Inventory management: Maintaining an adequate inventory of fabrics and supplies to avoid delays.

- Communication: Keeping clients informed about order progress and any potential challenges.

10. What sets you apart from other pre-pleaters?

I believe several factors set me apart from other pre-pleaters:

- Extensive experience: I have over 10 years of experience in the pre-pleating industry, giving me a deep understanding of the process and its nuances.

- Expertise in various fabrics: My experience in working with a wide range of fabrics enables me to optimize the pre-pleating process for each fabric type.

- Commitment to quality: I am dedicated to delivering high-quality pre-pleated fabrics that meet or exceed client expectations.

- Innovative approach: I am constantly exploring new techniques and technologies to push the boundaries of pre-pleating and create unique and stunning fabrics.

- Excellent communication skills: I believe in open and effective communication to ensure smooth collaboration with clients and team members.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Prepleater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Prepleater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Prepleater is accountable for cutting and preparing pleats on fabric to create various types of clothing and home linens. They play a crucial role in ensuring the accuracy and precision of pleating, which impacts the overall appearance and quality of the final product.

1. Fabric Preparation

Prepleaters begin by carefully examining the fabric to determine its suitability for pleating. They check for any defects or inconsistencies that could affect the pleating process.

- Inspect fabric for flaws, such as tears, holes, or uneven texture.

- Determine the appropriate grain line and mark it on the fabric.

2. Pleating

Prepleaters use a specialized machine to create pleats in the fabric. They adjust the machine settings according to the desired pleat size and style.

- Set up and operate pleating machines to create various pleat styles (e.g., box pleats, accordion pleats, knife pleats).

- Make adjustments to the machine settings to achieve the desired pleat depth, width, and sharpness.

3. Finishing

After pleating, Prepleaters inspect the fabric to ensure there are no errors or defects. They also apply finishing touches to enhance the appearance of the pleats.

- Inspect pleats for accuracy, uniformity, and symmetry.

- Press and steam pleats to set them in place and create a crisp finish.

4. Quality Control

Prepleaters are responsible for maintaining the quality of the pleating process. They regularly calibrate and maintain equipment to ensure optimal performance.

- Monitor production processes to identify and resolve any issues or deviations from standards.

- Maintain and calibrate pleating equipment to ensure consistent and accurate results.

Interview Tips

Preparing for an interview can help boost your confidence and chances of success. Here are some key tips to help you ace the interview for a Prepleater role:

1. Research the Company and Position

Take time to learn about the company’s history, values, and the specific requirements of the Prepleater role. This information will help you tailor your answers to the interviewer’s questions.

- Visit the company website to gather information about their products, services, and company culture.

- Review the job description thoroughly to understand the key responsibilities and qualifications for the role.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice answering them out loud to gain confidence and improve your delivery.

- Prepare for questions about your experience in fabric preparation, pleating techniques, and quality control.

- Practice describing your attention to detail, problem-solving abilities, and commitment to quality.

3. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience that make you a suitable candidate for the role. Provide specific examples to support your claims.

- Quantify your accomplishments whenever possible. For instance, “Increased pleating accuracy by 15% through implementing new quality control measures.”

- Use keywords from the job description in your answers to demonstrate your alignment with the company’s requirements.

4. Ask thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. It also allows you to gather additional information about the company and the position.

- Inquire about the company’s growth plans and industry trends.

- Ask about the training and development opportunities available for employees.

Next Step:

Now that you’re armed with the knowledge of Prepleater interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Prepleater positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini