Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Preservative Filler Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Preservative Filler Machine Operator so you can tailor your answers to impress potential employers.

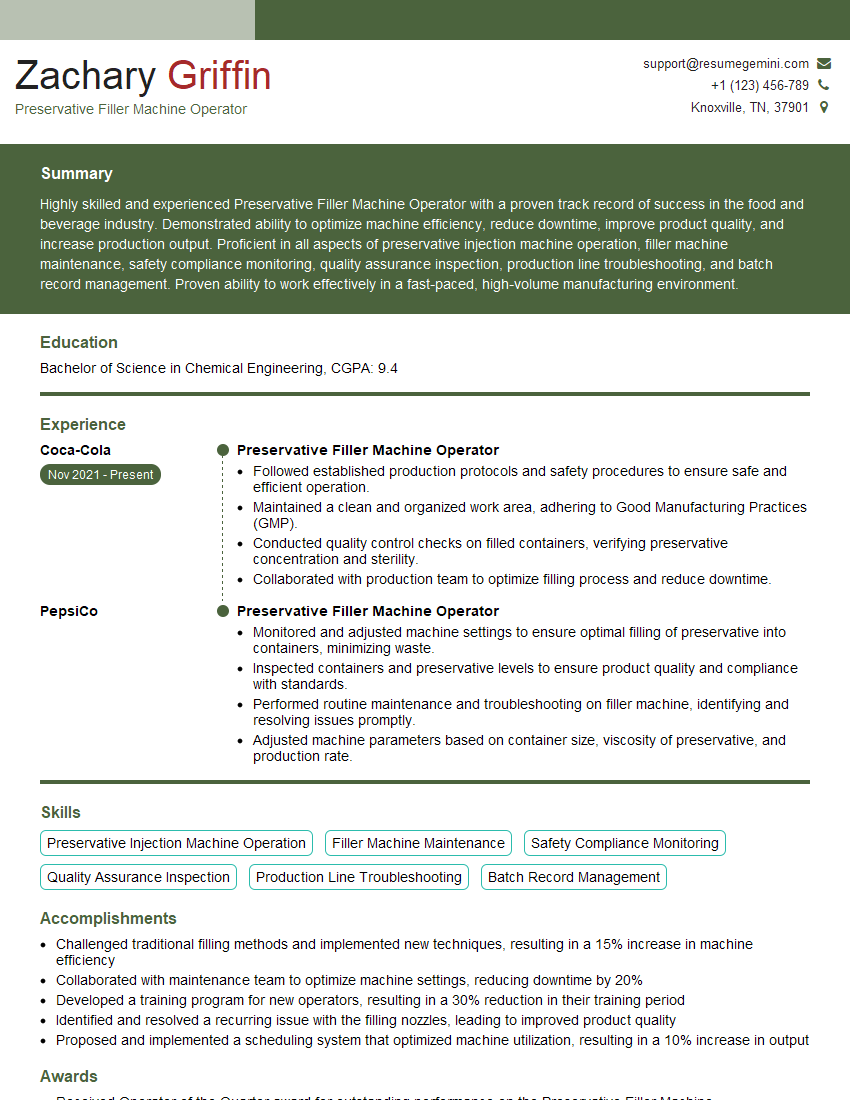

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Preservative Filler Machine Operator

1. What are the key responsibilities of a Preservative Filler Machine Operator?

- Operate preservative filler machines to fill containers with preservatives.

- Maintain and clean machines to ensure optimal performance.

- Monitor production lines to ensure quality control.

- Inspect containers for defects and remove any damaged or contaminated products.

- Follow safety protocols and regulations.

2. What are the different types of preservative filler machines?

Types of Preservative Filler Machines

- Volumetric fillers dispense a precise volume of preservative.

- Gravimetric fillers measure the weight of the preservative being dispensed.

- Inline fillers are integrated into a production line, allowing for continuous filling.

- Stand-alone fillers are used for smaller production runs or for filling containers that require special handling.

Advantages and Disadvantages of Different Types

- Volumetric fillers are simple to operate and maintain, but they can be less accurate than gravimetric fillers.

- Gravimetric fillers are more accurate, but they can be more complex to operate and maintain.

- Inline fillers are efficient and can handle high production volumes, but they can be more expensive than stand-alone fillers.

- Stand-alone fillers are less expensive and more flexible than inline fillers, but they are less efficient.

3. What are the safety precautions that should be taken when operating a preservative filler machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Follow lockout/tagout procedures when performing maintenance on the machine.

- Keep the work area clean and free of clutter.

- Be aware of the location of emergency stop buttons and fire extinguishers.

- Do not operate the machine if you are feeling tired or under the influence of drugs or alcohol.

4. How do you troubleshoot a preservative filler machine that is not filling containers properly?

- Check the fill head for blockages or damage.

- Inspect the product supply line for leaks or blockages.

- Calibrate the machine according to the manufacturer’s instructions.

- Check the settings for the fill volume and fill speed.

- Replace any worn or damaged parts.

5. What are the different types of preservatives used in food and beverage products?

- Chemical preservatives, such as sodium benzoate, potassium sorbate, and calcium propionate, inhibit the growth of bacteria and mold.

- Natural preservatives, such as vinegar, citric acid, and rosemary extract, also inhibit the growth of bacteria and mold, but they are derived from natural sources.

- Physical preservatives, such as heat and cold, can also be used to prevent the growth of bacteria and mold.

6. What are the different methods used to apply preservatives to food and beverage products?

- Preservatives can be added directly to food and beverage products during processing.

- Preservatives can be applied to the surface of food and beverage products.

- Preservatives can be incorporated into packaging materials.

7. What are the quality control procedures for preservative filler machines?

- Regular calibration of the machine.

- Inspection of containers for defects.

- Monitoring of product quality.

- Documentation of all quality control procedures.

8. What are the maintenance procedures for preservative filler machines?

- Regular cleaning of the machine.

- Inspection of the machine for wear and tear.

- Replacement of any worn or damaged parts.

- Lubrication of the machine.

9. What are the different types of containers used for preservative filler machines?

- Plastic bottles

- Glass bottles

- Metal cans

- Pouches

- Tubes

10. What are the challenges of working as a Preservative Filler Machine Operator?

- The work can be repetitive and monotonous.

- The work environment can be noisy and dusty.

- The work can be physically demanding.

- The work can be stressful, especially during peak production periods.

- The work can be dangerous, as there is a risk of injury from machinery or chemicals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Preservative Filler Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Preservative Filler Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Preservative Filler Machine Operators are responsible for operating and maintaining preservative filler machines, which dispense preservatives into food and beverage products. They ensure that the machines are running smoothly and efficiently, and that the products are properly filled and sealed. The key job responsibilities include:

1. Machine Operation

Starting, stopping, and controlling the preservative filler machine.

- Maintaining the proper filling level.

- Adjusting the machine according to the product being filled.

2. Equipment Maintenance

Performing routine maintenance on the machine, including cleaning, lubricating, and replacing parts.

- Identifying and troubleshooting any problems with the machine.

- Performing minor repairs.

3. Product Quality Control

Monitoring the product being filled to ensure that it meets quality standards.

- Filling products according to specifications.

- Checking for leaks or other product defects.

4. Safety and Compliance

Following all safety protocols for operating the machine.

- Wearing appropriate safety gear.

- Maintaining a clean and organized work area.

Interview Tips

Preparing for an interview for a Preservative Filler Machine Operator position requires a combination of technical knowledge and understanding of the industry. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company’s website, press releases, and social media pages to gain insights into their culture, values, and current projects relevant to the field.

- Identify the specific requirements of the position you’re applying for and tailor your answers to highlight your relevant skills and experience.

- Practice answering common interview questions related to your technical abilities, problem-solving skills, and teamwork experience.

2. Highlight Your Technical Expertise

Emphasize your understanding of the principles and operations of preservative filler machines, including their mechanics, electrical components, and safety features.

- Provide specific examples of your experience in maintaining and troubleshooting these machines.

- Discuss your knowledge of different types of preservatives and their application methods.

3. Showcase Your Quality Control Skills

Demonstrate your experience in adhering to quality standards and maintaining product integrity.

- Highlight your ability to identify and resolve product defects.

- Explain your knowledge of quality control procedures and your commitment to ensuring product safety.

4. Emphasize Your Safety Consciousness

Stress your adherence to safety protocols and your understanding of the importance of maintaining a safe work environment.

- Describe your experience in following safety guidelines and using appropriate personal protective equipment.

- Discuss your knowledge of industry regulations and best practices related to machine operation safety.

5. Prepare Questions for the Interviewer

Preparing thoughtful questions to ask the interviewer demonstrates your interest and engagement in the role and the company.

- Ask about the specific challenges and responsibilities associated with the position.

- Enquire about the company’s commitment to safety and quality.

- Show your eagerness to learn and contribute to the team’s success.

Next Step:

Now that you’re armed with the knowledge of Preservative Filler Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Preservative Filler Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini