Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Press Brake Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

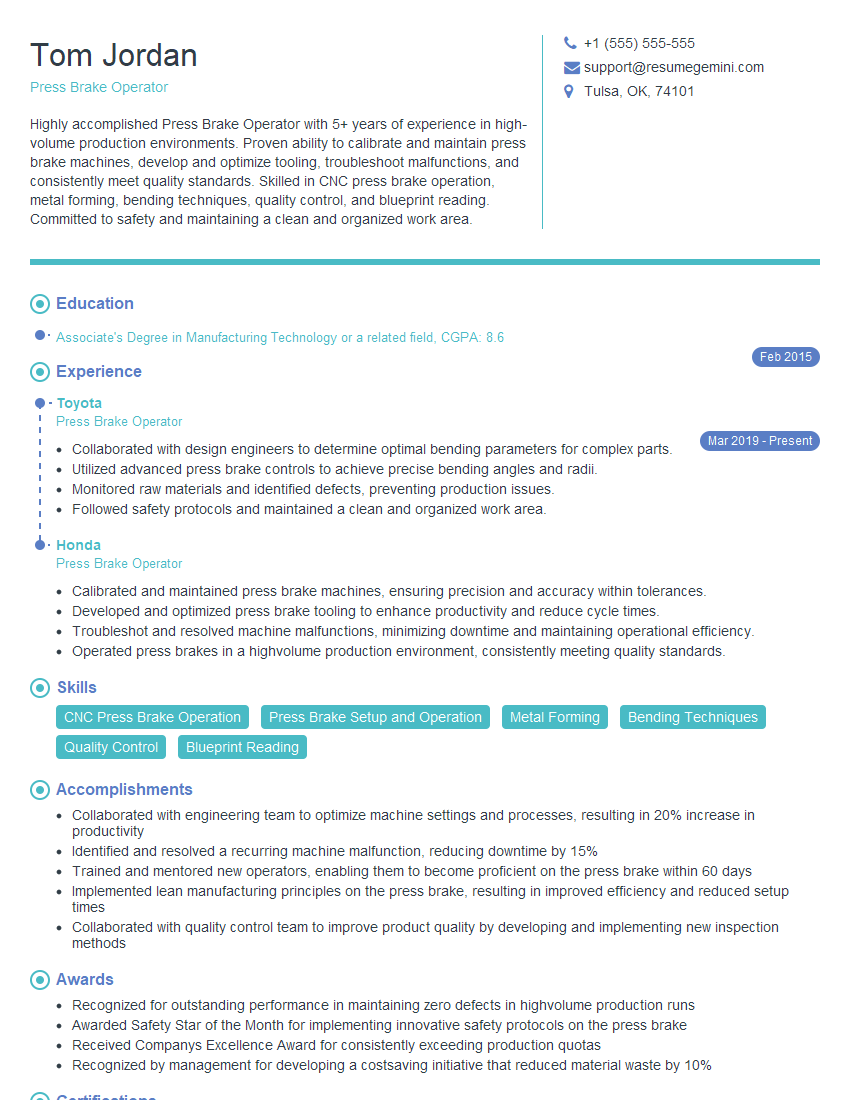

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Press Brake Operator

1. What is the purpose of a tonnage rating on a press brake?

The tonnage rating indicates the maximum force that the press brake can exert on the workpiece. It is important to choose a press brake with a tonnage rating that is appropriate for the thickness and type of material you will be bending.

2. What are the different types of press brake dies?

V-dies

- Used for bending V-shaped channels

- Available in various angles and sizes to accommodate different material thicknesses

Punch and die sets

- Used for bending specific shapes and profiles

- Customizable to create unique bends

Air bending dies

- Used for bending without leaving a mark on the workpiece

- Utilize a cushion of air to support the workpiece

3. What is the difference between a bottom bend and a top bend?

A bottom bend is made by bending the workpiece around a die that is positioned at the bottom of the press brake. A top bend is made by bending the workpiece around a die that is positioned at the top of the press brake.

4. What are the main factors that affect the accuracy of a press brake bend?

- Die selection

- Material thickness

- Workpiece length

- Machine settings

- Operator skill

5. What are the safety precautions that should be taken when operating a press brake?

- Wear proper safety gear, including gloves, safety glasses, and earplugs

- Keep hands and fingers away from the point of operation

- Use die guards and other safety devices

- Be aware of pinch points

- Follow proper lockout/tagout procedures

6. What are some common problems that can occur when operating a press brake, and how can they be resolved?

- Problem: Bent parts are not accurate Solution: Check die alignment, machine calibration, and workpiece positioning

- Problem: Wrinkling or cracking of the workpiece Solution: Use the correct die radius, apply less pressure, or use a different material

- Problem: Machine is making excessive noise Solution: Check for loose bolts, worn gears, or other mechanical issues

7. What is the difference between a hydraulic press brake and a mechanical press brake?

Hydraulic press brake

- Uses hydraulic fluid to generate pressure

- Provides more precise control over bending force and speed

- Typically more expensive than mechanical press brakes

Mechanical press brake

- Uses a flywheel and clutch to generate pressure

- Less precise than hydraulic press brakes

- Generally more affordable than hydraulic press brakes

8. What are the different types of press brake controls?

Manual controls

- Operator manually sets the bending parameters

- Requires skilled operators

CNC controls

- Computer-controlled system that automates bending operations

- Provides greater accuracy and repeatability

Adaptive controls

- Advanced type of CNC control that automatically adjusts bending parameters based on material properties

- Optimizes bending process and reduces scrap

9. What is the importance of proper maintenance for a press brake?

- Prevents breakdowns and costly repairs

- Ensures accurate and efficient bending operations

- Reduces the risk of workplace accidents

10. How can a press brake operator improve their skills and knowledge?

- Attend training courses and workshops

- Read technical manuals and articles

- Practice and experiment with different bending techniques

- Seek guidance from experienced operators and supervisors

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Press Brake Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Press Brake Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Press Brake Operators are responsible for operating press brake machines to bend and shape metal into various forms. They work with blueprint specifications and other technical drawings to ensure the accurate fabrication of products.

1. Machine Operation

Operate press brake machines to bend, form, and shape metal parts.

- Set up press brake machines according to job specifications.

- Load and unload metal parts from the machine.

- Monitor the bending process and make adjustments as needed.

2. Quality Control

Inspect finished parts for accuracy and quality.

- Use measuring tools to ensure parts meet specifications.

- Identify and correct any defects or errors.

3. Machine Maintenance

Perform routine maintenance on press brake machines.

- Lubricate moving parts.

- Clean and inspect machines for wear and tear.

- Report any maintenance issues to supervisors.

4. Safety Compliance

Follow all safety regulations and procedures.

- Wear appropriate personal protective equipment.

- Maintain a clean and organized work area.

- Report any safety hazards to supervisors.

Interview Tips

Preparing for a press brake operator interview can help you make a great impression and increase your chances of success.

1. Research the Company and Industry

Take the time to research the company you’re applying to and the industry in which they operate. This will help you understand their business needs and the specific requirements of the press brake operator position.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Technical Skills

Review your technical skills and practice operating press brake machines. This will help you demonstrate your proficiency and knowledge of the equipment.

- Set up a mock press brake machine and practice bending and shaping metal parts.

- Study technical drawings and blueprint specifications to understand how to interpret them.

3. Highlight Your Safety Awareness

Emphasize your safety awareness and understanding of safety regulations. This is an important aspect of press brake operator jobs.

- Explain your experience with operating press brake machines in a safe manner.

- Describe your knowledge of safety protocols and procedures.

4. Prepare for Common Interview Questions

Research common interview questions for press brake operators and prepare thoughtful answers.

- Tell me about your experience operating press brake machines.

- How do you ensure the accuracy and quality of finished parts?

- What are some of the safety measures you follow when operating press brake machines?

- How do you handle complex or challenging press brake operations?

- What are your strengths and weaknesses as a press brake operator?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Press Brake Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Press Brake Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.