Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Press Loader interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Press Loader so you can tailor your answers to impress potential employers.

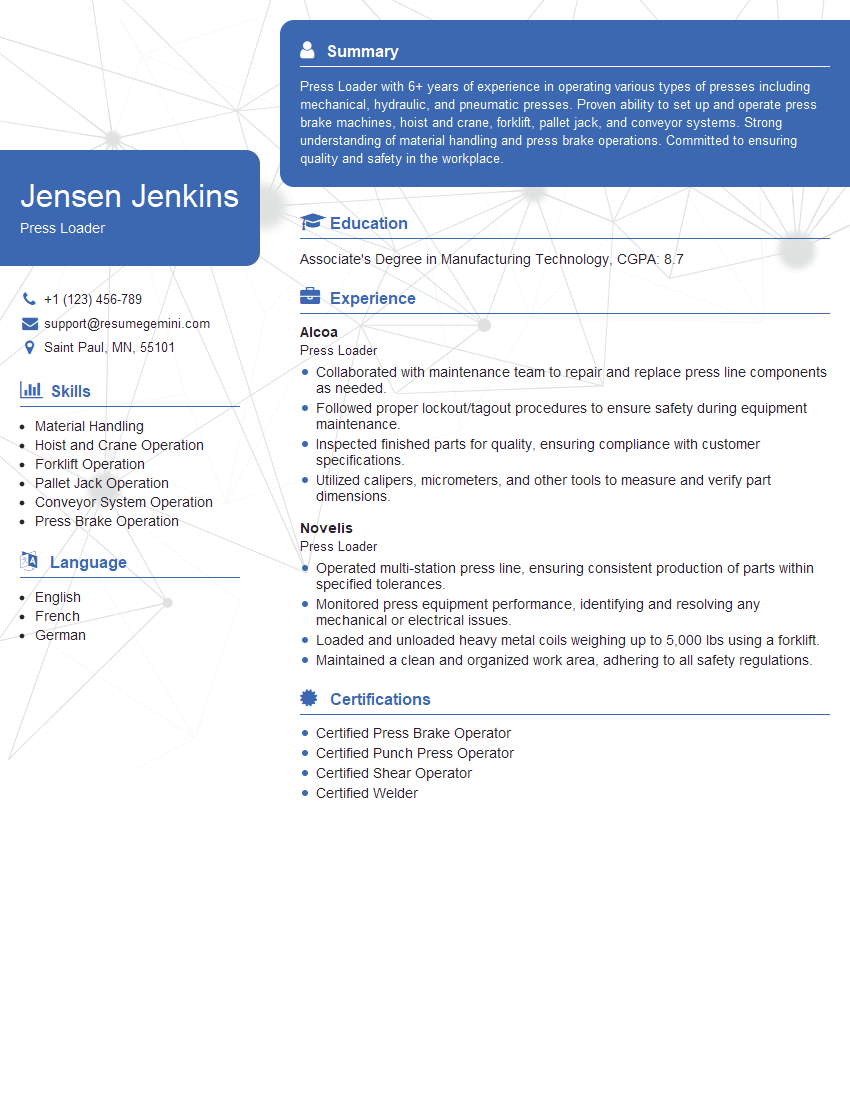

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Press Loader

1. Explain the primary responsibilities of a Press Loader?

- Loading and unloading printing presses with paper, ink, and other materials.

- Operating and maintaining printing presses to ensure optimal performance.

- Inspecting printed materials for defects and making necessary adjustments.

- Cleaning and maintaining the printing press and work area.

2. Describe the key technical skills and knowledge required for a Press Loader?

Proficient in operating various types of printing presses

- Knowledge of printing terminology and processes

- Ability to read and interpret technical drawings

- Strong mechanical aptitude

- Excellent attention to detail

Safety

- Adheres to all safety regulations and guidelines.

- Wears appropriate personal protective equipment.

- Reports any unsafe conditions or practices.

3. How do you ensure the quality of printed materials?

- Visually inspect printed materials for defects such as smudges, streaks, or misalignments.

- Use measuring tools to ensure that printed materials meet specifications.

- Make adjustments to the printing press as needed to correct defects.

- Keep a log of all quality checks performed.

4. How do you troubleshoot and resolve common printing press problems?

- Identify the source of the problem by observing the symptoms and checking the equipment.

- Consult technical manuals or consult with a supervisor to determine the appropriate solution.

- Implement the solution and test the equipment to ensure that the problem is resolved.

- Document the troubleshooting process and the solution for future reference.

5. Describe your experience in working with different types of printing materials?

- Experience in working with a variety of printing materials, including paper, cardboard, plastic, and metal.

- Knowledge of the different properties of each material and how to handle them properly.

- Ability to adjust the printing press settings to accommodate different materials.

6. How do you stay up-to-date on the latest printing technologies?

- Attend industry conferences and workshops

- Read trade publications

- Consult with equipment manufacturers and suppliers

- Participate in online forums and discussion groups

7. What is your understanding of color matching and calibration?

- Color matching is the process of ensuring that the colors printed on the press match the colors specified in the design.

- Calibration is the process of adjusting the printing press to ensure that it is producing consistent colors.

- Importance of color matching and calibration for ensuring the accuracy and quality of printed materials.

8. How do you manage multiple printing jobs with different deadlines?

- Prioritizing jobs based on deadlines and customer requirements

- Scheduling and coordinating printing tasks efficiently

- Communicating with customers and keeping them updated on the progress of their jobs

- Managing resources and equipment effectively to avoid delays

9. What is your experience in working in a team environment?

- Experience working in a team environment in a print shop or related industry.

- Ability to collaborate with colleagues, share knowledge, and support each other.

- Commitment to teamwork and achieving common goals.

10. Why are you interested in working as a Press Loader for our company?

- Interest in the printing industry and a desire to contribute to the production of high-quality printed materials.

- Alignment of skills and experience with the requirements of the job.

- Enthusiasm for working in a fast-paced and demanding environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Press Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Press Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Press Loader is a crucial member of the manufacturing or production team. Their primary responsibilities include:1. Loading Press with materials

Press Loaders are responsible for loading the printing press with raw materials such as paper, metal, or other substrates. This involves manually or using automated equipment to feed the materials into the press.

- Ensure materials meet specifications and are loaded correctly to prevent jams or damage to the press.

- Monitor the loading process and make adjustments as needed to maintain consistent material flow.

2. Operating and monitoring Press

Once the materials are loaded, Press Loaders operate the press to create the desired product. This involves setting up and adjusting the press according to the production specifications.

- Monitor the press during operation to ensure it is running smoothly and producing quality products.

- Make necessary adjustments to the press settings to optimize production efficiency and quality.

3. Unloading finished products

After the printing process is complete, Press Loaders are responsible for unloading the finished products from the press. This typically involves manually or using automated equipment to remove the printed materials.

- Inspect the finished products to ensure they meet quality standards and are ready for further processing or packaging.

- Package and label the finished products according to customer specifications.

4. Maintenance and cleaning

To ensure the press operates efficiently and produces high-quality products, Press Loaders are also involved in basic maintenance and cleaning tasks.

- Clean the press regularly to remove debris and prevent malfunctions.

- Perform minor maintenance tasks, such as changing filters or lubricating moving parts, to keep the press in optimal condition.

Interview Tips

To ace an interview for a Press Loader position, candidates should:1. Research the company and the role

Familiarize yourself with the company’s industry, products or services, and the specific responsibilities of the Press Loader role. This demonstrates your interest and preparation.

- Visit the company website, read industry news, and research the specific press equipment used.

- Prepare questions to ask the interviewer about the company, the role, and the team you would be working with.

2. Highlight relevant skills and experience

Emphasize your mechanical aptitude, attention to detail, and ability to work in a fast-paced and repetitive environment. If you have previous experience as a Press Loader or in a similar role, be sure to highlight your accomplishments.

- Quantify your experience by providing specific examples of how you have improved efficiency or maintained equipment in previous roles.

- Use action verbs and industry-specific terminology to demonstrate your expertise.

3. Demonstrate safety awareness

Press Loaders work with heavy machinery and materials, so safety is paramount. Emphasize your understanding of safety protocols and your commitment to adhering to them.

- Discuss your experience with safety training or certifications.

- Share examples of how you have identified and mitigated potential hazards in previous roles.

4. Be prepared for physical demands

The job of a Press Loader requires physical strength and stamina. Be prepared to discuss your ability to lift heavy objects, stand for long periods, and work in a physically demanding environment.

- Provide examples of your physical fitness and endurance.

- Explain how you have maintained your physical well-being in previous roles.

5. Show enthusiasm and willingness to learn

Press Loaders play a vital role in the manufacturing or production process. Demonstrate your enthusiasm for this role and your desire to contribute to the team’s success.

- Express your interest in learning new skills and technologies related to press operation and maintenance.

- Convey your willingness to take on additional responsibilities and support your colleagues.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Press Loader, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Press Loader positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.