Are you gearing up for an interview for a Press Machine Feeder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Press Machine Feeder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

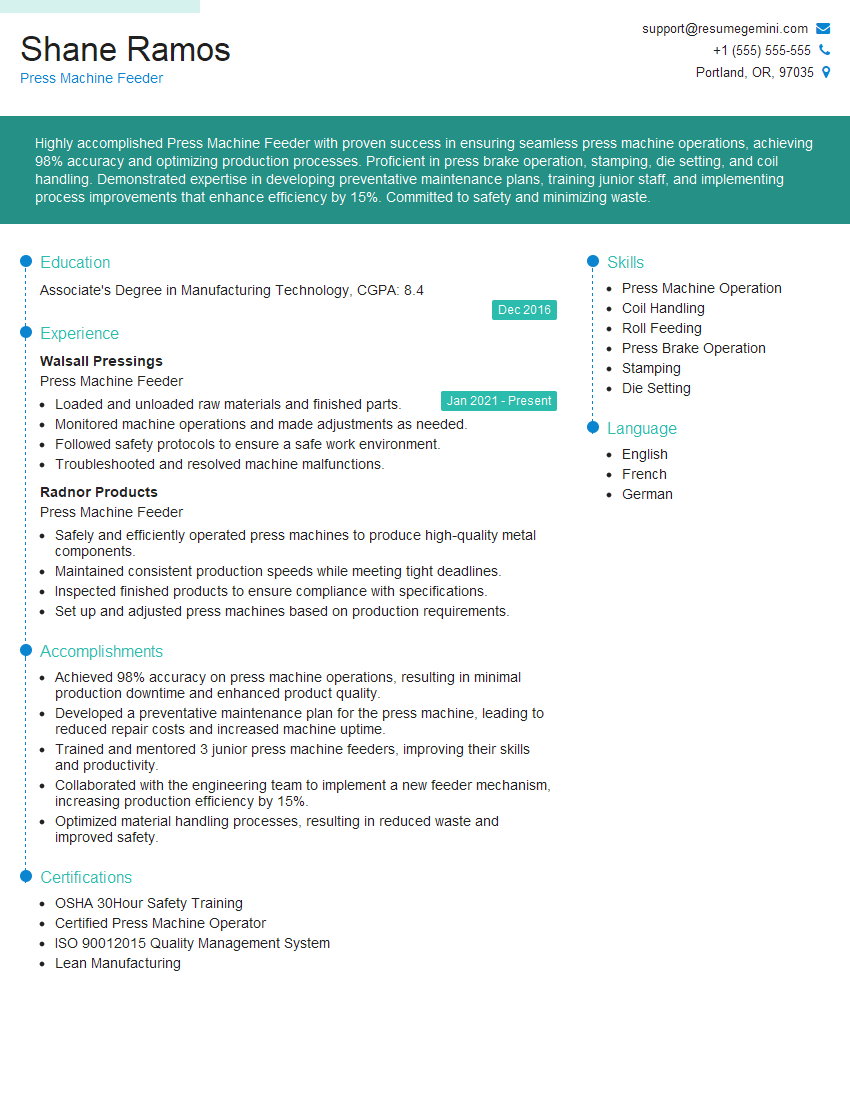

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Press Machine Feeder

1. Describe the steps involved in feeding a press machine?

The steps involved in feeding a press machine are:

- Load the material into the machine.

- Position the material on the die.

- Activate the machine to press the material.

- Remove the finished product from the machine.

2. What are the different types of materials that can be fed through a press machine?

The different materials that can be fed through a press machine include:

- Metal

- Plastic

- Wood

- Paper

- Fabric

3. What are the safety precautions that should be followed when operating a press machine?

The safety precautions that should be followed when operating a press machine include:

- Always wear safety glasses.

- Never wear loose clothing or jewelry.

- Keep your hands clear of the machine while it is in operation.

- Be aware of the location of the emergency stop button.

- Never operate the machine when you are tired or distracted.

4. What is the difference between a mechanical press and a hydraulic press?

A mechanical press uses a flywheel to generate the force needed to press the material. A hydraulic press uses hydraulic fluid to generate the force.

- Mechanical press: Uses a flywheel to generate the force. The flywheel is connected to the ram, which moves up and down to press the material.

- Hydraulic press: Uses hydraulic fluid to generate the force. The hydraulic fluid is pumped into a cylinder, which moves the ram up and down to press the material.

5. What are the different types of dies that can be used in a press machine?

The different types of dies that can be used in a press machine include:

- Blanking dies

- Forming dies

- Piercing dies

- Bending dies

- Coining dies

6. What are the factors that affect the quality of the finished product?

The factors that affect the quality of the finished product include:

- The type of material being used

- The type of die being used

- The pressure being applied

- The temperature of the material

- The speed of the machine

7. How do you maintain a press machine?

To maintain a press machine, you should:

- Keep the machine clean and free of debris.

- Lubricate the machine regularly.

- Inspect the machine for any damage or wear and tear.

- Have the machine serviced by a qualified technician on a regular basis.

8. What are the troubleshooting tips for a press machine?

Some troubleshooting tips for a press machine include:

- Check the power supply.

- Check the hydraulic fluid level.

- Check the air pressure.

- Inspect the machine for any damage or wear and tear.

- Contact a qualified technician for assistance.

9. What is the importance of preventive maintenance for a press machine?

Preventive maintenance is important for a press machine because it can help to:

- Reduce the risk of breakdowns.

- Extend the life of the machine.

- Improve the quality of the finished product.

- Reduce the cost of maintenance.

10. What are your strengths as a press machine feeder?

My strengths as a press machine feeder include:

- I have a strong understanding of the principles of press machine operation.

- I am proficient in the use of a variety of press machine dies.

- I am able to maintain a high level of accuracy and precision in my work.

- I am a team player and I am always willing to help out my colleagues.

- I am a hard worker and I am always willing to go the extra mile.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Press Machine Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Press Machine Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Press Machine Feeders are responsible for operating and monitoring press machines, ensuring that they run smoothly and efficiently. Their primary duty is to feed materials into the press machine, while also monitoring the machine’s operation and making necessary adjustments.

1. Material Feeding

Feeders are responsible for loading and unloading materials into and out of the press machine.

- Load raw materials, such as metal sheets or plastic, into the machine’s hopper or feed chute.

- Unloading finished products from the machine after they have been pressed.

2. Machine Monitoring

Keep a close watch on the press machine’s operation to ensure that it is running smoothly.

- Monitor pressure, temperature, and other operating parameters.

- Identify and resolve any problems that may arise during operation.

3. Quality Control

Conduct quality checks on the finished products to ensure that they meet specifications.

- Inspect products for defects, such as scratches or dents.

- Take corrective action if any defects are found.

4. Maintenance

Perform basic maintenance on the press machine to keep it in good working condition.

- Clean and lubricate the machine regularly.

- Report any major maintenance issues to a supervisor or technician.

Interview Tips

Preparing for an interview for a Press Machine Feeder position requires research, practice, and a positive mindset. Here are some tips to help you ace your interview:

1. Research the Company and Position

Thoroughly research the company you’re applying to and the Press Machine Feeder position. This will give you a good understanding of their culture, values, and the specific responsibilities of the role.

- Visit the company’s website and social media pages.

- Review the job description carefully and make note of the key requirements.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Use the STAR method (Situation, Task, Action, Result) to structure your responses:

- Situation: Describe a specific situation where you demonstrated a relevant skill or experience.

- Task: Explain the task or challenge you faced in that situation.

- Action: Describe the specific actions you took to address the task.

- Result: Quantify or qualify the positive outcome of your actions.

3. Showcase Your Skills and Experience

During the interview, emphasize your relevant skills and experience. Highlight your ability to operate press machines, monitor production, and perform basic maintenance. Use specific examples to demonstrate your proficiency:

- Provide examples of how you have successfully resolved production issues.

- Describe your experience in maintaining and troubleshooting press machines.

4. Ask Thoughtful Questions

Asking thoughtful questions shows that you’re engaged and interested in the position. Prepare a few questions to ask the interviewer about the company, the role, or the industry:

- What are the company’s growth plans for the future?

- What opportunities are there for professional development within the organization?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Press Machine Feeder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.