Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Press Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

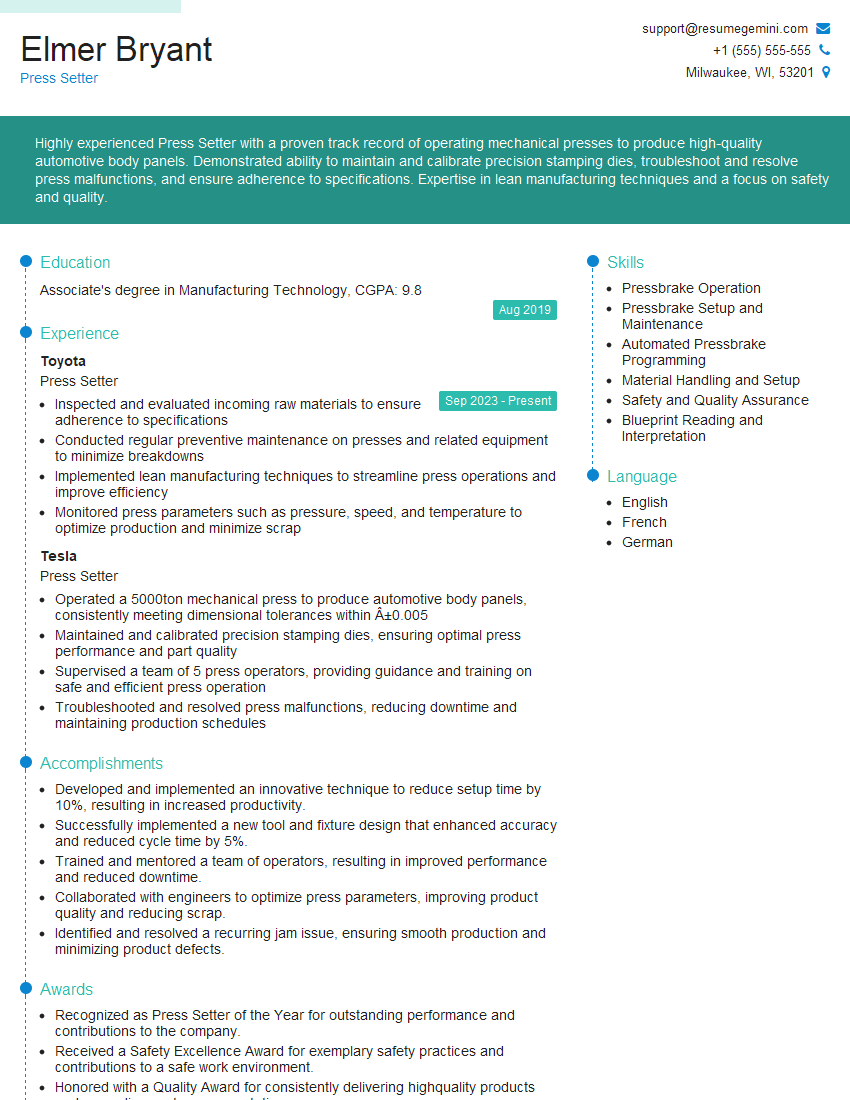

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Press Setter

1. What are the key responsibilities of a Press Setter?

As a Press Setter, I would be responsible for:

- Setting up and operating presses to produce metal stampings

- Maintaining and repairing presses and dies

- Inspecting and testing finished parts

- Following safety procedures and regulations

2. What are the different types of presses used in metal stamping?

Mechanical presses

- Use a flywheel and crankshaft to generate force

- High-speed and high-volume production

Hydraulic presses

- Use hydraulic fluid to generate force

- Slower, but more powerful and precise

Pneumatic presses

- Use compressed air to generate force

- Low-force, high-speed operations

3. What are the key factors to consider when selecting a die for a stamping operation?

When selecting a die, I would consider the following factors:

- Type of material being stamped

- Thickness of the material

- Desired shape and dimensions of the part

- Production volume

- Cost and availability of the die

4. What are the different types of die sets used in metal stamping?

Two-piece die sets

- Consist of a punch and die

- Simple and relatively inexpensive

Three-piece die sets

- Add a stripper plate to the two-piece die set

- Helps to prevent the material from sticking to the punch

Four-piece die sets

- Add a pressure pad to the three-piece die set

- Helps to hold the material in place during stamping

5. What are the common defects that can occur in metal stamping?

- Burrs

- Cracks

- Dents

- Scratches

- Warpage

I would identify the cause of the defect and take corrective action, such as adjusting the press settings, sharpening the dies, or replacing worn parts.

6. How do you maintain and repair presses and dies?

To maintain and repair presses and dies, I would:

- Inspect the press and dies regularly for wear and damage

- Lubricate the press and dies as needed

- Adjust the press settings as necessary

- Replace worn or damaged parts

7. How do you ensure that the presses are operating safely?

To ensure that the presses are operating safely, I would:

- Follow all safety procedures

- Inspect the press and dies before each use

- Never operate a press that is not in good working order

- Use proper personal protective equipment (PPE)

8. How do you measure productivity and efficiency in a press shop?

To measure productivity and efficiency in a press shop, I would:

- Track the number of parts produced per hour

- Calculate the scrap rate

- Identify areas for improvement

9. What is your experience with different types of metal stamping materials?

I have experience with a variety of metal stamping materials, including:

- Steel

- Aluminum

- Stainless steel

- Brass

- Copper

I understand the different properties of each material and how to adjust the press settings accordingly.

10. What is your experience with different types of metal stamping processes?

I have experience with a variety of metal stamping processes, including:

- Blanking

- Piercing

- Forming

- Bending

- Drawing

I understand the different requirements of each process and how to set up the press accordingly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Press Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Press Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Press Setters are responsible for the operation and maintenance of presses, which are used to form metal into desired shapes.

1. Machine Operation

Press Setters ensure that presses are operating correctly and efficiently and that they are producing high-quality products. Some of the specific tasks that Press Setters perform when operating presses include:

- Loading and unloading dies

- Setting up and adjusting presses

- Monitoring the press cycle

- Making minor adjustments to the press as needed

2. Maintenance and Repair

Press Setters are responsible for conducting routine preventive maintenance on the presses they operate such as lubricating moving parts and inspecting for wear and tear. They also perform minor repairs and troubleshooting to ensure that presses are functioning properly and repair or replace worn or damaged parts.

- Lubricating moving parts

- Replacing worn or damaged parts

- Making minor adjustments to the press

- Inspecting for wear and tear

3. Quality Control

Press Setters are responsible for monitoring the quality of the products that are produced on the presses they operate. They also perform quality checks and record data to ensure that the products meet the required specifications.

- Inspecting products for defects

- Measuring products to ensure that they meet the required specifications

- Logging data to track product quality

4. Safety

Press Setters are responsible for maintaining a safe work environment around the presses they operate. They must ensure that they are wearing the proper safety gear and that they are following all safety procedures to prevent accidents.

- Wearing the proper safety gear

- Following all safety procedures

- Reporting any unsafe conditions

- Taking part in safety training

Interview Tips

Preparing for an interview can be a daunting task, but there are a few key steps you can take to increase your chances of success.

1. Research the company and the position

Take some time to learn about the company you’re applying to and the position you’re interviewing for.

- Visit the company’s website to learn about their mission, values, and products or services.

- Read online reviews of the company to get a sense of what it’s like to work there.

- Look up the job description for the position you’re applying for to understand the specific requirements.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”

- Prepare your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills and experience.

3. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally for your interview. Also, be sure to arrive on time, as being late will reflect poorly on you.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive at the interview location 10-15 minutes early so that you have time to check in and get settled.

4. Be confident and enthusiastic

Confidence is key in an interview. Believe in yourself and your abilities, and let the interviewer know that you’re excited about the opportunity.

- Make eye contact with the interviewer and speak clearly and confidently.

- Smile and be enthusiastic about the position and the company.

- Ask questions at the end of the interview to show that you’re interested and engaged.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Press Setter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Press Setter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.