Are you gearing up for a career in Pressed or Blown Glass Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pressed or Blown Glass Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

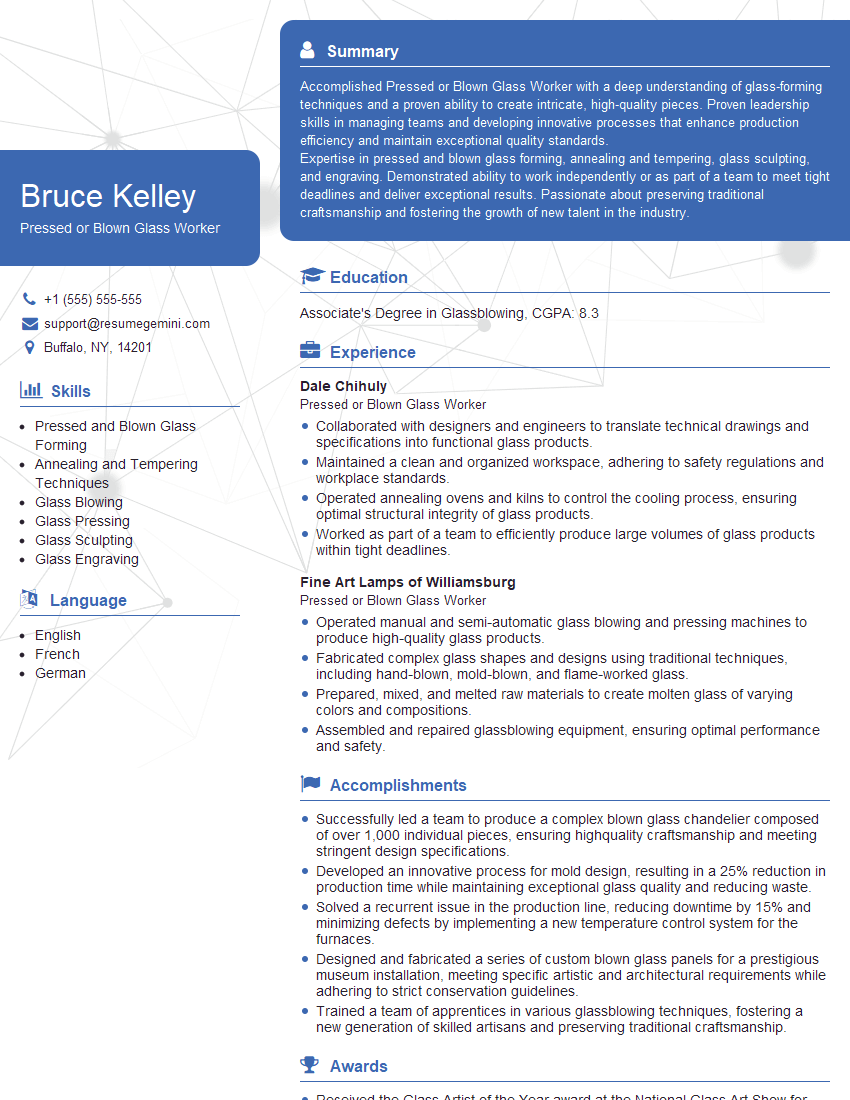

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pressed or Blown Glass Worker

1. Can you describe the process of creating a pressed glass item from start to finish?

The process of creating a pressed glass item from start to finish involves several steps:

- Mold preparation: The first step is to prepare the mold, which is typically made of metal or ceramic. The mold is engraved with the desired design or pattern.

- Glass preparation: Molten glass is gathered from the furnace and placed into the mold. The glass is then pressed into the mold using a plunger or ram, which forces the glass to take the shape of the mold.

- Annealing: After the glass has been pressed, it is annealed, or cooled slowly, to remove any internal stresses in the glass. This process helps to strengthen the glass and prevent it from breaking.

- Finishing: The final step is to finish the glass item. This may involve cutting, grinding, or polishing the glass to achieve the desired look and feel.

2. What are the key factors to consider when designing a blown glass item?

Factors affecting design in blown glass:

- Glass thickness: The thickness of the glass will affect its strength and durability. Thicker glass is more durable, but it can also be more difficult to work with.

- Glass color: The color of the glass will affect its appearance and its ability to transmit light. Different colors of glass can also be combined to create unique effects.

- Shape and size: The shape and size of the glass item will affect its functionality and its aesthetic appeal. It is important to consider the intended use of the item when designing its shape and size.

Factors affecting execution in blown glass:

- Temperature: The temperature of the glass will affect its workability. Glass that is too hot will be too soft to work with, while glass that is too cold will be too brittle.

- Tools and equipment: The tools and equipment that are used to blow glass will affect the quality of the finished product. It is important to have the right tools for the job and to know how to use them properly.

- Skill and experience: The skill and experience of the glassblower will affect the quality of the finished product. It takes years of practice to become a skilled glassblower.

3. Can you troubleshoot some common problems that can occur during the glassblowing process?

Some common problems that can occur during the glassblowing process include:

- Bubbles: Bubbles can be caused by trapped air in the glass. To prevent bubbles, it is important to heat the glass evenly and to work quickly.

- Cracks: Cracks can be caused by thermal shock, which occurs when the glass is heated or cooled too quickly. To prevent cracks, it is important to heat and cool the glass slowly and evenly.

- Deformation: Deformation can be caused by gravity or by the force of the glassblower’s tools. To prevent deformation, it is important to support the glass properly and to use the tools gently.

4. What are the different types of glass that can be used for pressed or blown glasswork?

There are many different types of glass that can be used for pressed or blown glasswork, including:

- Soda-lime glass: This is the most common type of glass, and it is made from soda ash, lime, and silica. Soda-lime glass is relatively inexpensive and easy to work with, but it is not as strong or durable as other types of glass.

- Borosilicate glass: This type of glass is made from boric oxide, silica, and other materials. Borosilicate glass is very strong and durable, and it is often used for scientific and industrial applications.

- Lead crystal: This type of glass is made from lead oxide, silica, and other materials. Lead crystal is very heavy and durable, and it has a beautiful sparkle. Lead crystal is used for a variety of decorative and functional objects.

5. What are the safety precautions that must be taken when working with glass?

When working with glass, it is important to take the following safety precautions:

- Wear eye protection: Glass can shatter into sharp pieces, so it is important to wear eye protection when working with it.

- Wear gloves: Gloves will protect your hands from cuts and burns.

- Use sharp tools: Sharp tools will help you to cut glass cleanly and safely.

- Keep your work area clean: A clean work area will help to prevent accidents.

6. What are the different techniques that can be used to decorate glass?

There are many different techniques that can be used to decorate glass, including:

- Sandblasting: This technique uses a stream of sand to etch a design into the glass.

- Engraving: This technique uses a sharp tool to carve a design into the glass.

- Painting: This technique uses paint to create a design on the glass.

- Kiln firing: This technique uses a kiln to fuse glass pieces together or to apply a decorative finish to the glass.

7. What are the different uses for pressed or blown glass?

Pressed or blown glass can be used for a variety of purposes, including:

- Functional objects: Pressed or blown glass can be used to create a variety of functional objects, such as dishes, cups, and vases.

- Decorative objects: Pressed or blown glass can also be used to create decorative objects, such as sculptures, lamps, and jewelry.

- Industrial applications: Pressed or blown glass can also be used for industrial applications, such as in the production of lenses and scientific instruments.

8. What are the current trends in pressed or blown glasswork?

Some of the current trends in pressed or blown glasswork include:

- The use of recycled glass: Many glassblowers are now using recycled glass in their work, which helps to reduce waste and protect the environment.

- The use of new technologies: New technologies, such as 3D printing, are being used to create new and innovative glass designs.

- The use of traditional techniques: Traditional glassblowing techniques are still being used to create beautiful and unique pieces of glasswork.

9. What is your favorite type of glass to work with? Why?

My favorite type of glass to work with is borosilicate glass because it is very strong and durable. It is also very clear, which makes it ideal for creating pieces that are both beautiful and functional.

10. What are your career goals?

My career goals are to become a skilled glassblower and to create beautiful and unique pieces of glasswork. I would also like to teach others how to blow glass so that they can experience the joy of this craft.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pressed or Blown Glass Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pressed or Blown Glass Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a highly skilled craftsman, a Pressed or Blown Glass Worker plays a critical role in creating stunning glass objects, from intricate art pieces to functional tableware. The key responsibilities of this position include:

1. Glass Preparation

Prepare glass for pressing or blowing by selecting the appropriate raw materials, melting the glass, and coloring or adding other additives to achieve desired effects.

2. Pressing or Blowing

Use specialized tools and techniques to press or blow molten glass into various shapes and designs. This involves controlling the amount of heat, pressure, and air flow to create precise and unique pieces.

3. Glass Finishing

Perform post-forming processes such as annealing, grinding, polishing, and etching to refine the glass and enhance its appearance and durability.

4. Quality Control

Inspect and test glass products to ensure they meet established quality standards. Identify and correct any defects or imperfections to maintain the reputation and integrity of the company.

Interview Preparation Tips

To ace an interview for a Pressed or Blown Glass Worker position, candidates should prioritize the following preparation tips:

1. Research the Company

Familiarize yourself with the company’s history, values, and specialization in the glass industry. This demonstrates your genuine interest and understanding of their business.

2. Practice Glass-Related Skills

If possible, practice your glass pressing or blowing techniques in advance. You may be asked to demonstrate your skills during the interview, so proficiency and confidence are crucial.

3. Highlight Your Passion

Emphasize your passion for artistry and craftsmanship. Explain how working with glass inspires you and satisfies your creative drive.

4. Research Emerging Trends

Demonstrate your knowledge of current trends and advancements in glassworking. This indicates your commitment to staying updated and applying innovative techniques in your work.

5. Prepare Questions

Ask thoughtful questions about the company’s glass production process, safety protocols, or opportunities for professional development. This shows your engagement and interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pressed or Blown Glass Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!