Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Presser interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Presser so you can tailor your answers to impress potential employers.

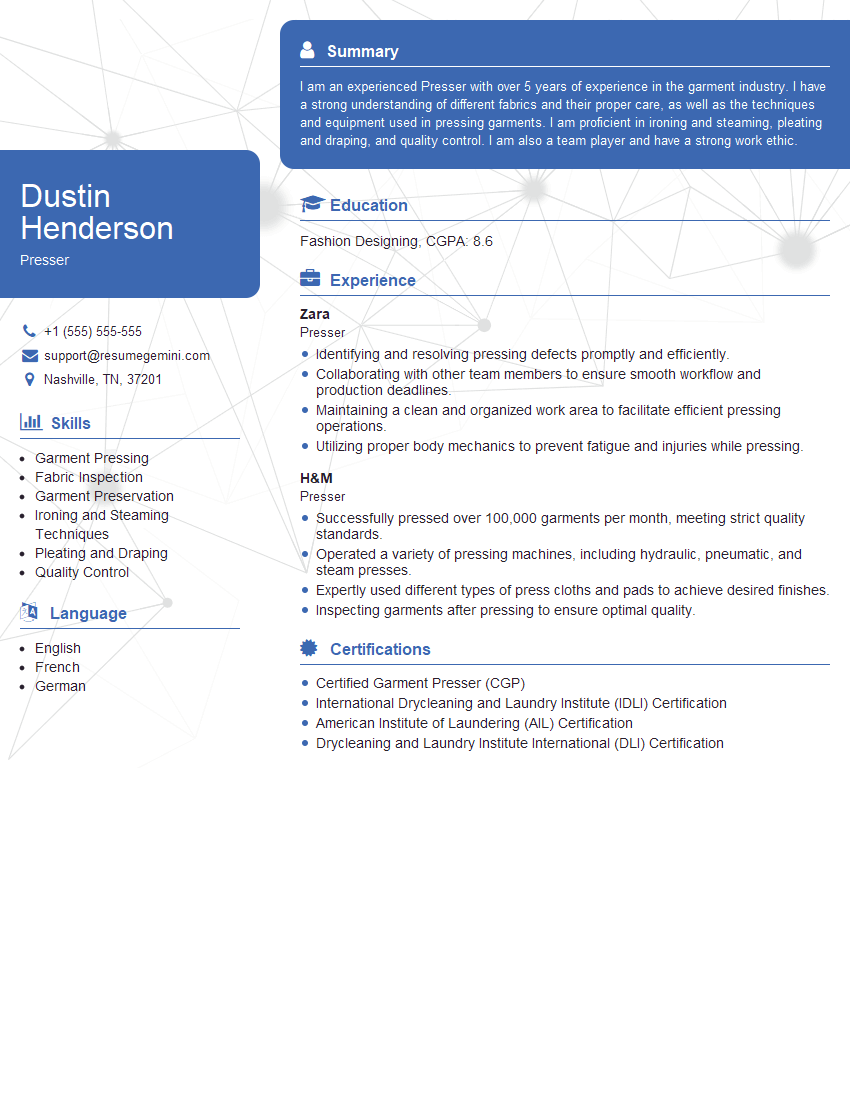

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Presser

1. What are the different types of ironing machines used in the industry? Describe their functions and applications.

Answer: * Flatwork Ironers: These are used for flat linens such as sheets, pillowcases, and tablecloths. They can be either single-pass or double-pass machines. * Rotary Ironers: These are used for shaped garments such as shirts, blouses, and pants. They use a rotating drum to iron the garments. * Press Irons: These are used for small items such as collars, cuffs, and pockets. They are hand-held machines that use heat and pressure to iron the garments. * Vacuum Ironers: These use suction to hold the garments in place while they are being ironed. This helps to prevent creases and wrinkles. * Steam Ironers: These use steam to moisten the garments before they are ironed. This helps to relax the fibers and make them easier to iron. * Conveyor Ironers: These use a conveyor belt to move the garments through the ironing process. This helps to speed up the ironing process.

2. Explain the importance of maintaining proper temperature and pressure settings on an ironing machine.

How does it impact the quality of the finished product?

Answer: * Proper temperature settings: * – Ensure that the garments are ironed at the correct temperature for their fabric type. * – Too high a temperature can damage the fabric, while too low a temperature will not remove the wrinkles. * Proper pressure settings * – Ensure that the garments are ironed with the correct amount of pressure. * – Too much pressure can flatten the fabric and remove its natural drape, while too little pressure will not remove the wrinkles.

Impact on the quality of the finished product

- Improper temperature settings can cause the fabric to scorch, discolor, or shrink.

- Improper pressure settings can cause the fabric to pucker, wrinkle, or lose its shape.

3. Describe the different types of fabrics and how they should be ironed to achieve the best results.

Answer: * Natural fibers: * – Cotton: Iron on high heat with steam. * – Linen: Iron on high heat with steam. * – Silk: Iron on low heat with no steam. * – Wool: Iron on low heat with a damp cloth. * Synthetic fibers: * – Polyester: Iron on low heat with no steam. * – Nylon: Iron on low heat with no steam. * – Acrylic: Iron on low heat with no steam. * Blends: * – Blend of natural and synthetic fibers: Iron on the setting for the most delicate fiber in the blend.

4. What are the common problems that can occur when ironing and how can they be prevented or corrected?

Answer: * Scorching: * – Caused by ironing at too high a temperature. * – Can be prevented by using the correct temperature setting for the fabric type. * Wrinkling: * – Caused by ironing the fabric too quickly or with too little pressure. * – Can be prevented by ironing the fabric slowly and with the correct amount of pressure. * Puckering: * – Caused by ironing the fabric with too much pressure. * – Can be prevented by using the correct amount of pressure. * Loss of shape: * – Caused by ironing the fabric while it is still wet. * – Can be prevented by allowing the fabric to dry completely before ironing.

5. What are the safety precautions that should be taken when using an ironing machine?

Answer: * Never leave the ironing machine unattended. * Always unplug the ironing machine when not in use. * Never touch the hot soleplate of the ironing machine. * Always use the ironing machine on a stable surface. * Never iron on a wet surface. * Always follow the manufacturer’s instructions for using the ironing machine.

6. How do you maintain an ironing machine to ensure its longevity and optimal performance?

Answer: * Regular cleaning: Clean the soleplate of the ironing machine regularly with a damp cloth. * Descaling: Descale the ironing machine regularly to remove mineral deposits. * Lubrication: Lubricate the moving parts of the ironing machine regularly. * Inspection: Inspect the ironing machine regularly for any damage or wear and tear.

7. How do you troubleshoot common problems that may arise with an ironing machine?

Answer: * The ironing machine is not heating up: * – Check if the ironing machine is plugged in. * – Check if the thermostat is set to the correct temperature. * – Check if the heating element is damaged. * The ironing machine is leaking water: * – Check if the water tank is overfilled. * – Check if the water tank is cracked. * – Check if the water pump is damaged. * The ironing machine is making a strange noise: * – Check if there is any debris stuck in the ironing machine. * – Check if the bearings are worn out. * – Check if the motor is damaged.

8. How do you ensure the quality of the finished product when pressing garments?

Answer: * Use the correct temperature and pressure settings for the fabric type. * Iron the garment in the correct direction. * Use a pressing cloth to protect the garment from the heat of the iron. * Allow the garment to cool completely before folding or hanging it up.

9. What are the different types of pressing equipment used in the industry? Describe their functions and applications.

Answer: * Flatwork presses: * – Used for flat linens such as sheets, pillowcases, and tablecloths. * Rotary presses: * – Used for shaped garments such as shirts, blouses, and pants. * Steam presses: * – Used for delicate garments such as silk and lace. * Vacuum presses: * – Used for garments with a lot of detail, such as pleats and ruffles. * Fusing presses: * – Used for bonding two pieces of fabric together, such as when applying interfacing.

10. How do you maintain a clean and organized work area when pressing garments?

Answer: * Keep your work area tidy and free of clutter. * Put away all tools and materials when not in use. * Clean your pressing equipment regularly. * Dispose of waste materials properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Presser is responsible for the operation of high-pressure industrial machines to bond and shape a variety of materials.

Duties and Responsibilities

Some of the most common responsibilities that fall under this role include:

- Examining and measuring materials to determine pressure and heat settings for pressing operations.

- Loading and unloading materials into and out of the press.

- Operating presses to bond, shape, or finish materials according to specifications.

- Inspecting pressed materials for defects or imperfections.

- Performing adjustments to equipment and processes to ensure quality standards are met.

- Cleaning and maintaining equipment and work areas.

- Assisting with troubleshooting and repairs.

- Following safety procedures and maintaining a safe work environment.

- Adhering to quality control standards.

- Working as part of a team.

Interview Tips

Preparing for a job interview can be daunting, however, following some key tips and tricks can aid you in a job interview. Here are some essential tips to help candidates ace their interview for the Presser position:

Research the Company and Position

Before attending the interview, take the time to research the company and the specific Presser position. This will not only demonstrate your interest but will also provide context for your answers and questions during the interview.

- Review the company website to learn more about their mission, values, and products/services.

- If available, check the company’s social media pages to get a sense of their culture and industry involvement.

- Read job postings and descriptions to understand the specific requirements and expectations of the Presser role.

Practice Your Answers

Take the time to prepare thoughtful responses to common interview questions. Practice delivering your answers out loud to gain confidence and ensure clarity.

- Research common interview questions to get an idea of what you may be asked.

- Prepare concise and specific answers that highlight your skills and experience.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide concrete examples.

Dress Professionally

First impressions matter, so ensure you dress appropriately for the interview. Business casual attire is typically suitable for this type of position.

- Choose clean, pressed, and conservative clothing.

- Avoid wearing excessive jewelry or accessories.

- Consider the company culture and dress code when selecting your outfit.

Be Punctual and Polite

Respect the interviewer’s time and arrive for the interview on schedule or even slightly early.

- Factor in potential traffic or delays and plan your journey accordingly.

- Greet the interviewer with a firm handshake and make eye contact.

- Be polite, respectful, and professional throughout the interview.

Prepare Questions

Asking thoughtful questions demonstrates your interest in the position and the company. Prepare a few questions to ask the interviewer towards the end of the session.

- Ask about the company culture, opportunities for advancement, or specific projects related to the role.

- Inquire about the training and support provided to Pressers.

- Avoid asking questions about benefits or salary during the initial interview.

Follow-up

After the interview, take the time to send a thank-you note to the interviewer. This shows your appreciation and continued interest in the position.

- Reiterate your interest in the position and the company.

- Thank the interviewer for their time and consideration.

- Re-emphasize your key skills and qualifications.

Next Step:

Now that you’re armed with the knowledge of Presser interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Presser positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini