Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pressure Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

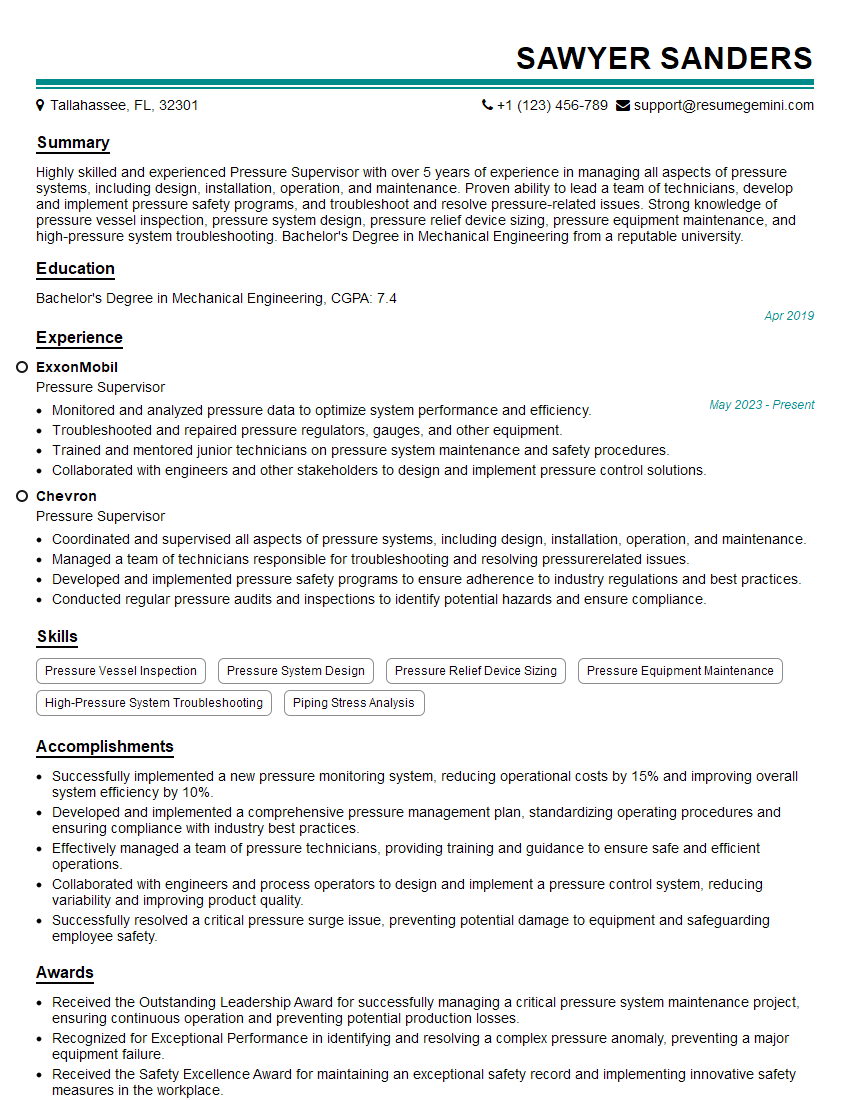

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pressure Supervisor

1. Explain the principles of pressure control and how you ensure it during drilling operations?

- Pressure control is critical to maintaining wellbore integrity and preventing blowouts.

- The primary principle is to balance the pressure in the wellbore with the pressure of the formation fluids.

- I use a combination of techniques, including mud weight management, choke adjustment, and blowout preventers, to maintain the desired pressure balance.

- I continuously monitor pressure readings and drilling parameters to identify any potential pressure issues and take immediate corrective actions.

2. Describe how you assess and mitigate risks associated with pressure control?

Risk assessment

- Review geological data and wellbore conditions to identify potential pressure hazards.

- Analyze mud properties, wellbore geometry, and equipment capabilities.

- Identify potential failure modes and develop contingency plans.

Risk mitigation

- Implement appropriate pressure control measures based on the risk assessment.

- Establish clear operating procedures and guidelines for pressure management.

- Ensure regular maintenance and testing of pressure control equipment.

- Foster a culture of safety and vigilance among the drilling crew.

3. How do you monitor and interpret pressure data during drilling?

- Use pressure gauges and sensors to monitor annular pressure, casing pressure, and hydrostatic pressure.

- Analyze pressure trends and identify any sudden changes or anomalies that may indicate a pressure control issue.

- Cross-check pressure readings from multiple instruments to ensure accuracy.

- Interpret pressure data in conjunction with other drilling parameters to assess wellbore stability and make informed decisions.

4. What are the different types of pressure control equipment and their functions?

- Blowout preventers (BOPs): Seal the wellbore to prevent uncontrolled fluid flow.

- Mud pumps: Circulate drilling fluid to maintain pressure and remove cuttings.

- Chokes: Regulate the flow of fluids from the wellbore, controlling pressure.

- Kelly valves: Installed on the top of the drill string to close off the wellbore in case of a blowout.

- Pressure gauges: Monitor pressure readings at various points in the drilling system.

5. How do you prepare for and respond to a kick?

Kick preparation

- Establish a kick detection plan based on wellbore conditions and drilling parameters.

- Train the drilling crew on kick recognition and response procedures.

- Ensure that all pressure control equipment is in good working order.

Kick response

- Activate the blowout preventer system to seal the wellbore.

- Increase mud weight or apply backpressure to control the kick.

- Circulate the kick out of the wellbore while maintaining pressure control.

- Investigate the cause of the kick and implement corrective measures to prevent recurrence.

6. How do you manage abnormal pressure zones while drilling?

- Identify abnormal pressure zones based on geological data and well log interpretations.

- Adjust mud weight and drilling parameters to maintain pressure control within the abnormal zone.

- Monitor pressure readings closely and use early kick detection techniques.

- Consider using specialized drilling techniques, such as managed pressure drilling or underbalanced drilling.

7. What are the key performance indicators (KPIs) you use to evaluate pressure control performance?

- Annular pressure variations

- Frequency of kicks detected

- Time to control kicks

- Mud weight management efficiency

- Reliability and performance of pressure control equipment

8. How do you ensure that the drilling crew is well-trained and competent in pressure control?

- Develop and deliver comprehensive training programs on pressure control principles and procedures.

- Conduct regular drills and simulations to assess crew competence.

- Provide ongoing coaching and mentoring to reinforce knowledge and skills.

- Maintain records of training and certifications for all crew members.

9. What are the latest advancements in pressure control technology that you are aware of?

- Automated pressure control systems

- Advanced kick detection algorithms

- Composite materials for blowout preventers

- Real-time pressure monitoring and data analytics

10. How do you stay updated on industry best practices and regulations related to pressure control?

- Attend industry conferences and seminars

- Review technical journals and publications

- Participate in professional organizations

- Consult with experts and subject matter specialists

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pressure Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pressure Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Pressure Supervisor

1. Managing Pressure Systems

- Ensuring the proper operation of pressure vessels, boilers, and other high-pressure systems.

- Conducting regular inspections, maintenance, and repairs on these systems to prevent pressure surges and other safety hazards.

2. Monitoring and Controlling Pressure

- Continuously monitoring the performance of pressure systems and taking corrective actions when necessary.

- Maintaining logs and records of pressure readings, ensuring compliance with regulatory requirements.

3. Troubleshooting and Problem-Solving

- Identifying and resolving problems in pressure systems, minimizing disruptions and ensuring safety.

- Investigating incidents related to pressure and implementing measures to prevent recurrence.

4. Safety and Compliance

- Ensuring compliance with all applicable safety regulations, including OSHA and industry standards.

- Conducting safety training and implementing safety protocols to protect personnel and prevent accidents.

5. Team Leadership and Supervision

- Leading and supervising a team of pressure equipment operators and maintenance technicians.

- Providing guidance, training, and performance evaluations to team members.

Interview Preparation Tips for Pressure Supervisor Candidates

1. Research the Company and Role

- Thoroughly research the company’s operations, industry, and specific role requirements.

- This shows your interest and understanding of the industry, enhancing your chances of impressing the interviewers.

2. Practice Competency-Based Questions

- Prepare for behavioral interview questions that assess your skills and experiences relevant to the job.

- Use the STAR method (Situation, Task, Action, Result) to describe specific examples that demonstrate your capabilities.

3. Highlight Safety Knowledge and Experience

- Emphasize your in-depth understanding of pressure vessel safety regulations and industry standards.

- Showcase your experience in conducting safety inspections, ensuring compliance, and implementing safety measures.

4. Demonstrate Team Leadership Skills

- Highlight your experience in leading and motivating a team of technical professionals.

- Provide examples of how you effectively delegated tasks, provided feedback, and fostered a positive work environment.

5. Prepare Technical Questions

- Expect technical questions related to pressure systems, equipment, and safety best practices.

- Review your technical knowledge and prepare clear and concise answers to specific questions you may encounter.

6. Dress Appropriately and Bring Relevant Materials

- Present yourself in a professional manner by dressing appropriately and arriving on time for the interview.

- Consider bringing a portfolio or presentation highlighting your work experience and qualifications.

7. Follow Up and Express Interest

- After the interview, follow up with the hiring manager thanking them for their time and reiterating your interest in the position.

- Expressing enthusiasm and following up professionally demonstrates your commitment to the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pressure Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!