Are you gearing up for a career in Primer Inserting Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Primer Inserting Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

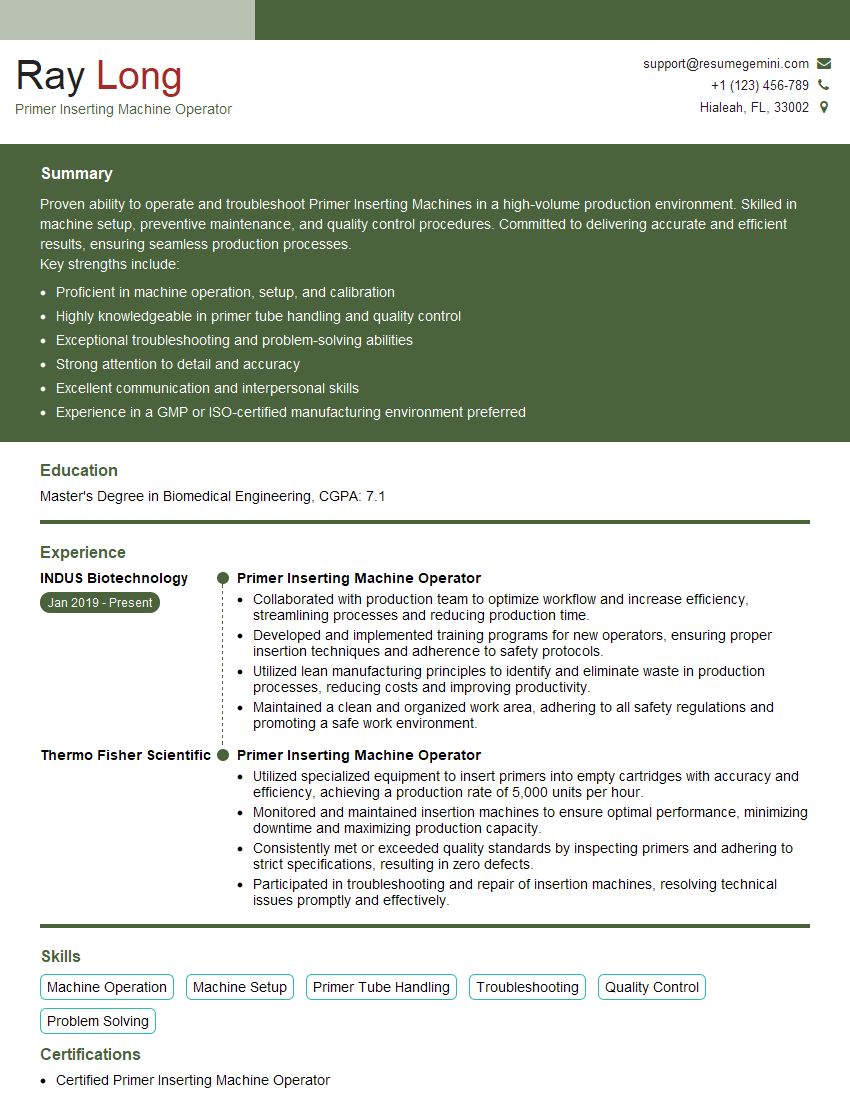

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Primer Inserting Machine Operator

1. What are the key responsibilities of a Primer Inserting Machine Operator?

As a Primer Inserting Machine Operator, my primary responsibilities include:

- Operating and maintaining primer inserting machinery to ensure efficient and accurate insertion of primers into cartridges.

- Monitoring machine performance, identifying malfunctions, and resolving issues promptly to minimize downtime.

2. How do you ensure the quality and accuracy of primer insertion?

To ensure quality and accuracy, I adhere to the following practices:

Quality Control Measures

- Conduct regular inspections of primers to verify their dimensions, integrity, and absence of defects.

- Calibrate and maintain machine settings precisely to ensure proper primer placement and depth.

Accuracy Verification

- Sample cartridges after each setup change or at specified intervals to assess insertion accuracy.

- Utilize measuring tools and gauges to verify proper primer alignment and seating.

3. What troubleshooting steps do you take when a primer inserting machine malfunctions?

When faced with a malfunction, I follow a systematic troubleshooting approach:

- Identify the problem by observing machine behavior and error messages.

- Refer to technical manuals and consult with experienced operators to determine possible causes.

- Perform visual inspections, check electrical connections, and clean components as necessary.

- Replace faulty parts and make necessary adjustments to restore machine functionality.

4. How do you prioritize tasks and manage multiple projects simultaneously?

Prioritizing tasks and managing multiple projects effectively is crucial in my role. I employ the following strategies:

- Establish clear priorities based on deadlines, importance, and impact.

- Create a structured work plan and allocate time for each task accordingly.

- Break down large or complex projects into smaller, manageable chunks.

- Delegate tasks to team members when necessary to ensure timely completion.

5. How do you stay updated on the latest technology and best practices in primer inserting?

To stay current and enhance my skills, I engage in the following activities:

- Attend industry conferences and workshops to learn about new techniques and equipment.

- Read technical journals and articles to keep pace with industry advancements.

- Network with other operators and share knowledge and best practices.

6. How do you handle working in a fast-paced production environment?

Working in a fast-paced production environment requires the ability to remain focused and efficient. I manage this by:

- Maintaining a clear understanding of production goals and deadlines.

- Prioritizing tasks and optimizing my workflow to maximize productivity.

- Communicating effectively with team members to coordinate efforts and minimize bottlenecks.

7. How do you ensure compliance with safety regulations and quality standards?

Maintaining safety and adhering to quality standards are paramount. I ensure compliance through the following practices:

- Familiarizing myself with and strictly following established safety protocols.

- Wearing appropriate personal protective equipment and using machinery safely.

- Adhering to quality control procedures, including inspections and documentation.

8. How do you measure your success as a Primer Inserting Machine Operator?

I evaluate my success based on the following metrics:

- Machine uptime and efficiency

- Accuracy and quality of primer insertion

- Minimal downtime due to machine malfunctions

- Compliance with safety and quality standards

9. Can you describe a specific instance where you successfully resolved a complex issue with a primer inserting machine?

Issue:

The machine was experiencing intermittent primer jams during insertion.

Troubleshooting and Resolution:

- Inspected the primer feed mechanism and discovered a damaged guide.

- Replaced the guide and adjusted the tension settings.

- Ran test cycles to verify proper primer alignment and insertion.

- The issue was resolved, and the machine resumed normal operation.

10. What are your career goals and aspirations?

As a motivated and results-oriented professional, I aspire to grow within the industry. My career goals include:

- Advance to a supervisory role where I can lead and mentor other operators.

- Contribute to process improvements and enhance operational efficiency.

- Stay abreast of industry advancements and share knowledge with my colleagues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Primer Inserting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Primer Inserting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Primer Inserting Machine Operator is responsible for the operation and maintenance of primer inserting machines, which are used to insert primers into ammunition. Their duties include setting up, operating, and adjusting the machine, as well as inspecting and maintaining the equipment to ensure that it is operating properly.

1. Machine Operation

The operator must be able to set up and operate the primer inserting machine according to the manufacturer’s instructions. This includes loading the machine with primers and ammunition, adjusting the settings, and starting and stopping the machine.

- Load the machine with primers and ammunition.

- Adjust the settings on the machine.

- Start and stop the machine.

- Monitor the machine’s operation.

2. Machine Maintenance

The operator must also be able to perform basic maintenance on the primer inserting machine. This includes cleaning the machine, lubricating the moving parts, and inspecting the machine for wear or damage.

- Clean the machine.

- Lubricate the moving parts.

- Inspect the machine for wear or damage.

- Make minor repairs to the machine.

3. Quality Control

The operator is responsible for ensuring that the machine is inserting primers into ammunition correctly. This includes inspecting the ammunition after it has been processed by the machine to ensure that the primers are properly seated and that there are no defects.

- Inspect the ammunition after it has been processed by the machine.

- Identify and correct any defects.

- Maintain records of the quality of the ammunition produced.

4. Safety

The operator must follow all safety procedures when operating the primer inserting machine. This includes wearing appropriate clothing and safety gear, and following the manufacturer’s instructions for safe operation.

- Wear appropriate clothing and safety gear.

- Follow the manufacturer’s instructions for safe operation.

- Report any safety concerns to the supervisor.

Interview Tips

Preparing for an interview can be nerve wracking, but following a few key tips can help you present yourself in the best possible light and increase your chances of getting the job.

1. Research the Company and the Position

Take some time to research the company you’re applying to and the position you’re interested in. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can find this information on the company’s website, in their annual reports, or through industry publications.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions in advance, so that you can deliver them confidently and concisely.

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of the interview shows that you’re interested in the position and that you’re taking the interview seriously. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”.

4. Follow Up After the Interview

After the interview, take some time to follow up with the interviewer. This could be a simple thank-you note or a brief email summarizing the main points of the interview and expressing your continued interest in the position.

5. Additional Tips for Primer Inserting Machine Operators

In addition to the general interview tips above, here are a few additional tips for primer inserting machine operators:

- Be prepared to discuss your experience with primer inserting machines.

- Be able to demonstrate your knowledge of the safety procedures for operating primer inserting machines.

- Be able to describe your quality control procedures.

- Be able to explain how you would troubleshoot a primer inserting machine if it malfunctioned.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Primer Inserting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!