Are you gearing up for an interview for a Print Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Print Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

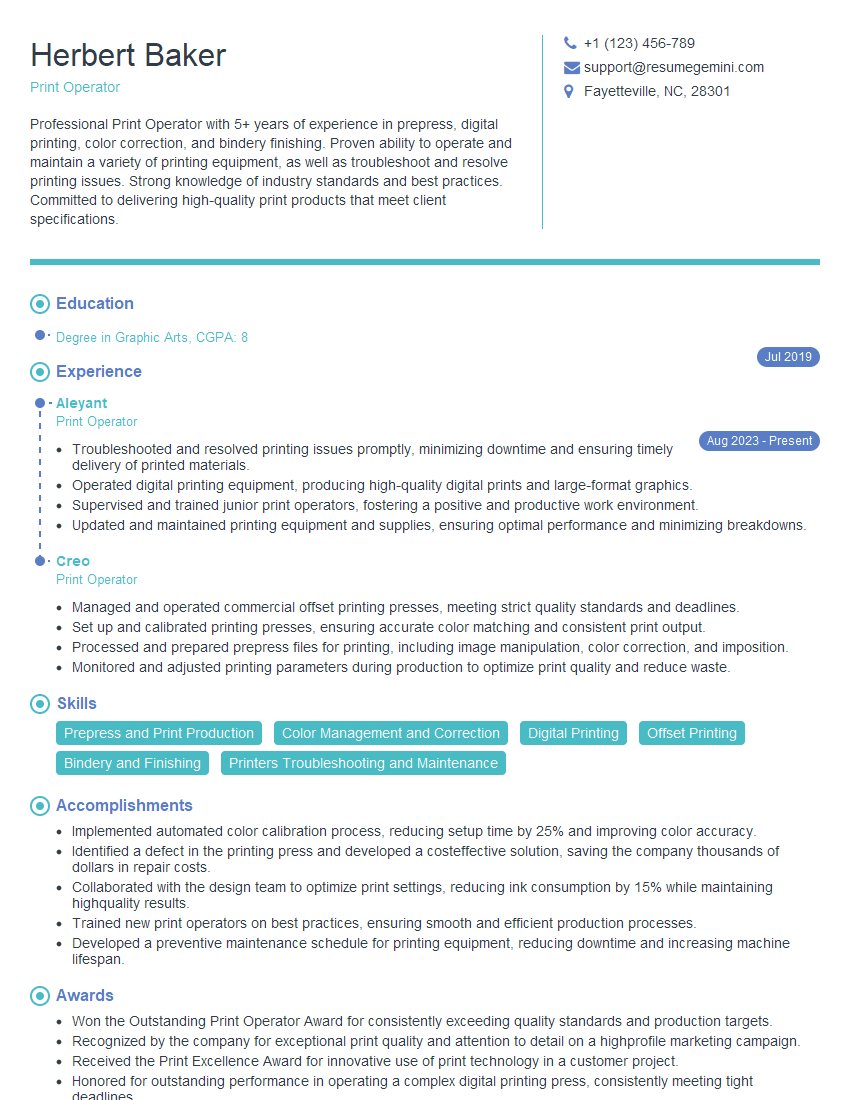

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Print Operator

1. How do you ensure the accuracy of the printed colors?

- Calibrate and maintain the printing press regularly to ensure color accuracy.

- Use color management software to create and match colors.

- Proof prints and compare them to the original designs to verify color accuracy.

2. What are the different types of printing processes and when would you use each one?

Offset printing

- Used for high-volume, high-quality printing.

- Suitable for a wide range of paper stocks and finishes.

Digital printing

- Used for short-run, quick-turnaround printing.

- Suitable for a variety of substrates, including paper, plastic, and fabric.

Flexographic printing

- Used for printing on flexible materials, such as packaging and labels.

- Durable and resistant to wear and tear.

3. How do you troubleshoot common printing problems, such as banding, ghosting, and misregistration?

- Identify the cause of the problem by examining the printed output and the printing equipment.

- Calibrate the printing press and adjust the settings accordingly.

- Clean or replace printing plates or rollers as needed.

- Use different paper stocks or adjust the press tension to address misregistration.

4. What techniques do you use to minimize waste and maximize efficiency in the printing process?

- Plan print jobs carefully to reduce setup time and material waste.

- Use efficient cutting and folding techniques to minimize paper trimming.

- Recycle and reuse scrap paper and other materials whenever possible.

5. How do you ensure the safety of yourself and others in the print shop environment?

- Follow all safety protocols and wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

- Operate printing equipment cautiously and avoid touching moving parts.

6. Describe your experience with different types of printing equipment, such as presses, cutters, and folders.

- Offset press: Operated a Heidelberg Speedmaster XL 106 for high-volume printing.

- Digital press: Used a Xerox Versant 80 for short-run, quick-turnaround printing.

- Cutter: Experienced in using a Polar 115 guillotine cutter for precise trimming.

- Folder: Proficient in operating a Heidelberg Stahlfolder TH 82-P for folding brochures and booklets.

7. How do you keep up with the latest developments in the printing industry?

- Attend industry trade shows and conferences.

- Read industry publications and online resources.

- Participate in online forums and discussions.

8. What are the key qualities of a successful Print Operator?

- Attention to detail and accuracy.

- Strong technical skills and knowledge of printing equipment.

- Ability to troubleshoot problems and make adjustments quickly.

- Excellent communication and interpersonal skills.

9. Why are you interested in this Print Operator position, and what makes you a suitable candidate?

- I am passionate about printing and have a strong understanding of the industry.

- My experience with a variety of printing equipment and processes makes me a versatile and efficient operator.

- I am detail-oriented, quality-conscious, and committed to producing exceptional printed products.

10. Describe a challenging printing project that you successfully completed, and what you learned from the experience.

- Printed a high-volume brochure for a major client with complex graphics and tight deadlines.

- Had to troubleshoot and resolve a color registration issue during the printing process.

- Learned the importance of meticulous planning, efficient problem-solving, and effective communication with the production team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Print Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Print Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Print Operators are responsible for operating and maintaining printing presses to produce high-quality printed materials. Their duties involve preparing printing jobs, setting up and calibrating equipment, and monitoring the printing process to ensure accurate and efficient production.

1. Preparing Printing Jobs

Prior to printing, Print Operators analyze job specifications, select appropriate materials, and prepare the necessary files for printing.

- Review print orders and determine paper type, ink colors, and print settings.

- Load paper and adjust printing press accordingly.

- Calibrate printing equipment to achieve optimal color accuracy and image quality.

2. Operating Printing Presses

Once the printing setup is complete, Print Operators initiate and oversee the printing process.

- Start and stop printing presses as needed.

- Monitor ink levels, paper feed, and print quality throughout the run.

- Make adjustments to printing settings as necessary to maintain consistency and prevent defects.

3. Maintaining Printing Equipment

To ensure smooth and efficient printing operations, Print Operators perform regular maintenance and troubleshooting procedures.

- Clean and lubricate printing presses.

- Inspect and replace worn or damaged parts.

- Troubleshoot and resolve printing issues promptly.

4. Quality Control

Print Operators are responsible for ensuring the quality of the printed materials produced. They inspect finished products and make adjustments to printing settings or equipment as needed.

- Inspect printed materials for defects such as color variations, smudges, or misalignments.

- Adjust printing settings to correct any quality issues.

- Coordinate with other departments to resolve quality concerns.

Interview Tips

To ace the Print Operator interview, it is essential to prepare thoroughly. Here are some tips to help you make a strong impression:

1. Research the Company and Role

Before the interview, take the time to research the printing company and the specific role you are applying for. This will give you a good understanding of the company’s business, its values, and the expectations for the Print Operator position.

- Visit the company’s website to learn about its history, services, and products.

- Read industry publications and articles to stay up-to-date on the latest printing technologies and trends.

- Search for news and reviews about the company to gain insights into its reputation and customer satisfaction.

2. Prepare for Technical Questions

Print Operator interviews often involve technical questions about printing equipment, processes, and quality control standards. Be prepared to discuss your experience and knowledge in these areas.

- Review the job description carefully and identify the key skills and qualifications required.

- Practice describing your experience in operating and maintaining printing presses, including specific models and technologies.

- Be ready to discuss your knowledge of printing materials, inks, and color management techniques.

3. Highlight Your Attention to Detail

Attention to detail is crucial for Print Operators. During the interview, emphasize your ability to identify and correct printing errors, ensuring high-quality output.

- Provide examples from your previous experience where you identified and resolved printing issues.

- Describe your quality control procedures and how you maintain consistent print quality.

- Explain how you handle complex or challenging printing jobs that require precision and accuracy.

4. Demonstrate Your Problem-Solving Skills

Printing operations can sometimes encounter unexpected challenges. Demonstrate your problem-solving abilities and how you approach technical difficulties.

- Describe situations where you encountered printing problems and explain how you diagnosed and resolved them.

- Emphasize your resourcefulness and willingness to learn new techniques to overcome printing challenges.

- Highlight your ability to work independently and make sound decisions under pressure.

Next Step:

Now that you’re armed with the knowledge of Print Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Print Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini