Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printed Circuit Board Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

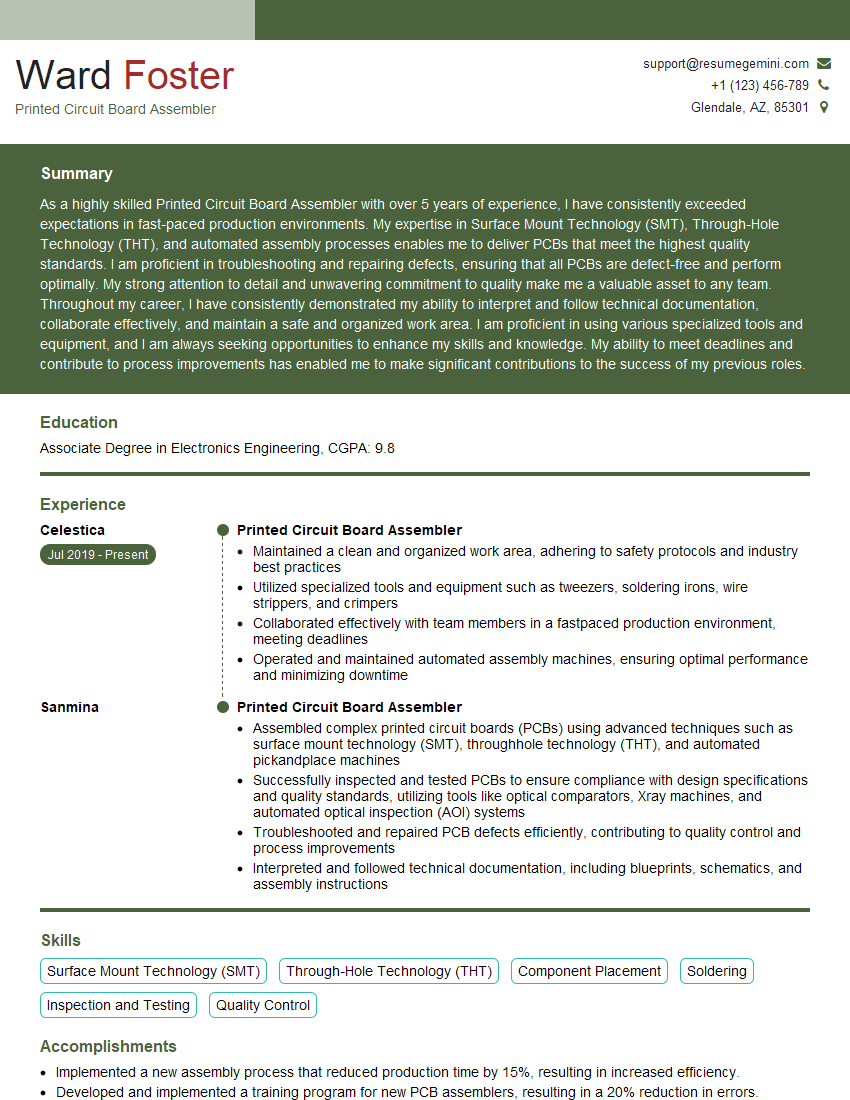

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Board Assembler

1. What is the purpose of solder mask in PCB assembly?

Solder mask is a protective coating applied to the surface of a printed circuit board (PCB) to prevent solder bridges and shorts. It also protects the copper traces from oxidation and corrosion.

2. What are the different types of soldering techniques used in PCB assembly?

Hand soldering

- Manual soldering using a soldering iron and solder

- Suitable for small-scale production and repairs

Wave soldering

- Melting solder in a wave and passing the PCB through it

- Automated process suitable for mass production

Reflow soldering

- Applying solder paste to the PCB and heating it in an oven

- Automated process suitable for surface-mount components

3. What are the key factors to consider when selecting components for a PCB assembly?

- Electrical and physical specifications

- Availability and cost

- Environmental factors (temperature, humidity, vibration)

- Compliance with industry standards and regulations

4. What are the most common defects that occur in PCB assembly and how can they be prevented?

- Solder bridges: Using solder paste stencils with the correct aperture size and printing alignment

- Solder voids: Using high-quality solder paste and ensuring proper reflow parameters

- Tombstoning: Using the correct solder paste viscosity and component placement techniques

- Component misalignment: Using pick-and-place machines with high accuracy and vision systems

5. What is the importance of quality control in PCB assembly?

- Ensures the reliability and performance of the final product

- Reduces the risk of defects and recalls

- Maintains customer satisfaction and reputation

- Improves overall efficiency and productivity

6. What are the different types of test methods used in PCB assembly?

Electrical testing

- In-circuit testing (ICT)

- Functional testing

Non-electrical testing

- Automated optical inspection (AOI)

- X-ray inspection

7. What are the environmental considerations in PCB assembly?

- Using lead-free solder and components

- Reducing waste and hazardous materials

- Complying with environmental regulations

- Promoting sustainability throughout the supply chain

8. What are the latest trends and advancements in PCB assembly technology?

- Miniaturization and high-density boards

- Flexible and rigid-flex PCBs

- Automated assembly and inspection systems

- Industry 4.0 and the Internet of Things (IoT)

9. What are your strengths and weaknesses as a Printed Circuit Board Assembler?

Strengths

- Strong attention to detail and accuracy

- Proficient in various soldering techniques

- Experience in high-volume assembly environments

- Excellent troubleshooting skills

Weaknesses

- Limited experience with exotic components

- Still developing my skills in automated inspection

10. Why are you interested in working as a Printed Circuit Board Assembler at our company?

I am eager to join your team because of your reputation for producing high-quality PCBs and your commitment to innovation. I believe that my skills and experience would be a valuable asset to your organization. I am particularly interested in the opportunity to learn from experienced professionals and contribute to the advancement of PCB assembly technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Board Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Board Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Printed Circuit Board (PCB) Assembler plays a vital role in the electronics industry by assembling and testing circuit boards used in various electronic devices. Here are the key job responsibilities of a PCB Assembler:

1. Board Preparation

Prepares circuit boards by cleaning, inspecting, and applying solder paste.

- Inspects boards for defects and makes necessary repairs.

- Applies thermal paste to designated areas of the board.

2. Component Placement

Accurately places electronic components on the circuit board according to the assembly drawing.

- Handles electronic components with care to prevent damage.

- Uses specialized tools and equipment to position and secure components.

3. Soldering

Solders components to the circuit board using a soldering iron.

- Applies solder to connections to ensure electrical conductivity.

- Inspects soldered joints for quality and makes adjustments as needed.

4. Inspection and Testing

Inspects assembled circuit boards for defects and conducts electrical tests to verify functionality.

- Uses visual inspection techniques to identify any anomalies or errors.

- Conducts electrical tests using specialized equipment to ensure board performance meets specifications.

5. Maintenance and Troubleshooting

Maintains and troubleshoots assembly equipment to ensure optimal performance.

- Performs regular maintenance tasks such as cleaning and calibrating equipment.

- Troubleshoots equipment issues and makes necessary repairs or adjustments.

Interview Tips

To ace an interview for a PCB Assembler position, it is important to prepare thoroughly and demonstrate your skills and knowledge. Here are some interview tips:

1. Research the Company

Before the interview, take the time to research the company you are applying to. Familiarize yourself with their products, industry reputation, and company culture. This knowledge will help you tailor your answers to the specific company and demonstrate your genuine interest.

2. Practice Your Technical Skills

PCB assembly requires strong technical skills. Practice soldering, component placement, and inspection techniques before the interview. You may also want to brush up on your knowledge of electrical circuits and testing procedures.

3. Highlight Your Attention to Detail

PCB assembly requires meticulous attention to detail. Emphasize your ability to work precisely and accurately, and provide examples from your previous experience where you demonstrated these skills.

4. Showcase Your Teamwork and Communication Skills

PCB assemblers often work in teams and must be able to communicate effectively with colleagues and supervisors. Highlight your ability to work collaboratively, follow instructions, and communicate clearly.

5. Prepare Questions

Asking well-thought-out questions during the interview shows that you are engaged and interested in the position. Prepare questions about the company’s assembly process, training opportunities, and potential career growth paths.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printed Circuit Board Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.