Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printed Circuit Board Assembly Group Leader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

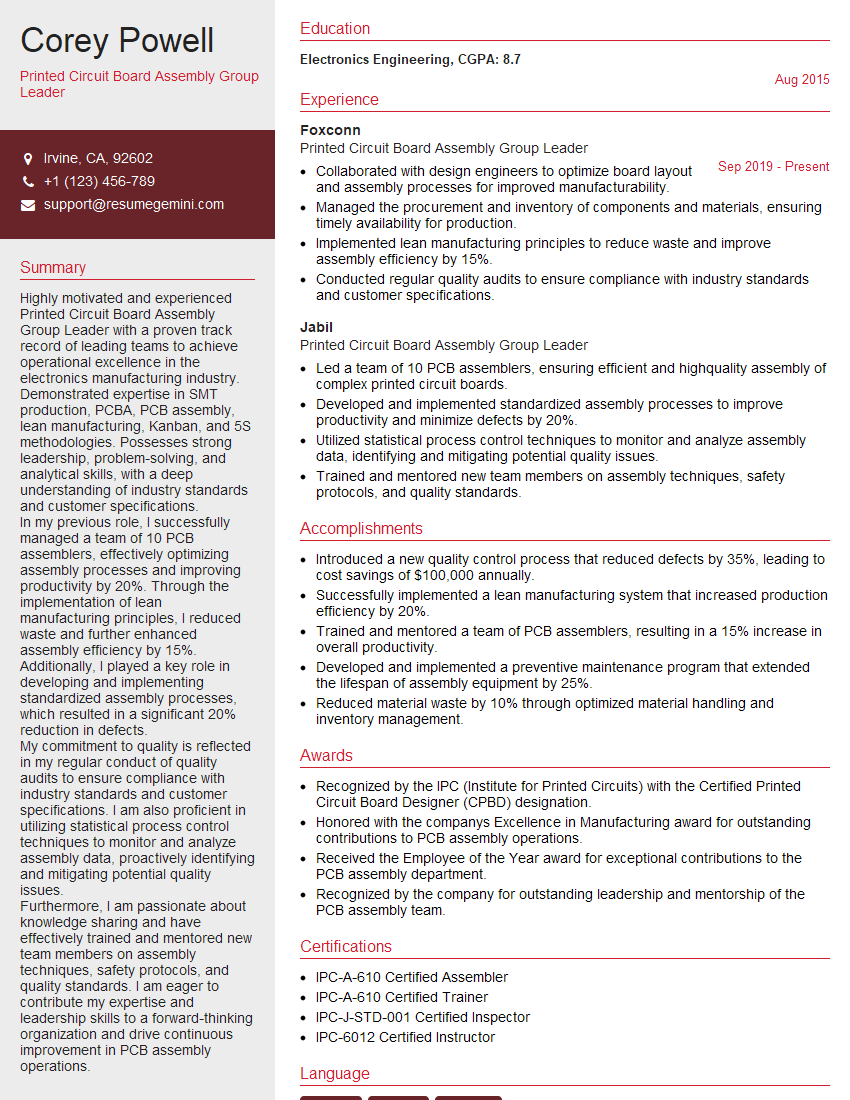

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Board Assembly Group Leader

1. How would you ensure that the PCBA meets the required specifications and quality standards?

- Implement a rigorous quality control process throughout the production line.

- Utilize testing equipment and procedures to verify component placement, solder joints, and functionality.

- Establish clear acceptance criteria and inspection standards.

- Monitor and review production data to identify areas for improvement.

- Foster a culture of continuous improvement and defect prevention.

2. Describe the key techniques used in PCBA assembly and their respective advantages and disadvantages.

Surface Mount Technology (SMT)

- Advantages: Smaller size, higher density, reduced weight, automated assembly.

- Disadvantages: Component placement accuracy, heat sensitivity, rework challenges.

Through-Hole Technology (THT)

- Advantages: Durability, mechanical strength, prototyping ease.

- Disadvantages: Larger size, lower density, manual assembly.

3. What are the typical equipment used in PCBA assembly and their functions?

- Pick-and-Place Machines: Place components on the PCB accurately.

- Reflow Ovens: Solder components using controlled heating and cooling.

- Wave Soldering Machines: Solder components through holes using molten solder.

- Automated Optical Inspection (AOI) Machines: Inspect PCBs for defects.

- Electrical Test Equipment: Verify the functionality and performance of PCBs.

4. How would you optimize the PCBA assembly process for efficiency and cost-effectiveness?

- Streamline the workflow and minimize bottlenecks.

- Automate processes where possible.

- Optimize component placement and routing.

- Utilize efficient materials and components.

- Implement lean manufacturing principles.

- Continuously monitor and improve production metrics.

5. Discuss the challenges associated with high-volume PCBA assembly and how you would address them.

- Maintaining high quality standards in high-volume production.

- Ensuring timely delivery of products.

- Managing supply chain complexities.

- Implementing automated testing and inspection procedures.

- Training and retaining skilled technicians.

6. How would you lead and motivate your team to achieve the best possible results?

- Foster a positive and collaborative work environment.

- Set clear goals and expectations.

- Recognize and reward employee achievements.

- Provide continuous training and development opportunities.

- Empower team members to make decisions and take ownership.

- Create a culture of continuous improvement.

7. What are the latest trends and advancements in PCBA technology?

- Miniaturization and higher component density.

- Advanced packaging technologies (e.g., BGA, CSP).

- Flexible and conformable PCBs.

- Smart and connected PCBs (e.g., embedded sensors, wireless communication).

- Industry 4.0 and Internet of Things (IoT) integration.

8. How do you stay updated with the latest industry developments and best practices?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Network with other industry professionals.

- Participate in online forums and discussion groups.

- Undertake professional development courses.

9. Describe a situation where you had to troubleshoot a complex PCBA assembly issue. How did you approach the problem and what was the solution?

Provide a specific example from your experience, highlighting your problem-solving skills, analytical approach, and ability to identify and resolve technical issues.

10. How would you ensure that your team is adequately trained and skilled to handle the challenges of PCBA assembly?

- Develop and implement a comprehensive training program.

- Provide on-the-job training and mentorship.

- Cross-train team members on different aspects of the assembly process.

- Encourage continuous learning and skill development.

- Partner with educational institutions and industry experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Board Assembly Group Leader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Board Assembly Group Leader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Printed Circuit Board Assembly Group Leader is responsible for overseeing the assembly of printed circuit boards (PCBs) in a production environment. This role involves managing a team of assemblers, ensuring that PCBs are assembled according to specifications, and troubleshooting any issues that arise during the assembly process.

1. Manage a Team of Assemblers

The Group Leader is responsible for hiring, training, and supervising a team of assemblers. This involves setting work schedules, assigning tasks, and providing guidance and support to the team. The Group Leader must also ensure that the team is meeting production goals and quality standards.

2. Ensure PCBs are Assembled According to Specifications

The Group Leader is responsible for ensuring that all PCBs are assembled according to the customer’s specifications. This involves reviewing the design documentation, identifying the components required, and ensuring that the components are placed correctly on the PCB. The Group Leader must also verify that the PCB is assembled according to the correct solder profile.

3. Troubleshooting Assembly Issues

During the assembly process, issues may arise that require troubleshooting. The Group Leader is responsible for identifying the root cause of the issue and implementing a solution. This may involve working with the engineering team to redesign the PCB or modifying the assembly process.

4. Maintain a Safe and Efficient Work Environment

The Group Leader is responsible for maintaining a safe and efficient work environment. This involves ensuring that the work area is clean and organized, and that all equipment is functioning properly. The Group Leader must also ensure that the team is following all safety protocols.

Interview Tips

To prepare for an interview for a Printed Circuit Board Assembly Group Leader position, it is important to have a strong understanding of the key job responsibilities and to be able to articulate your skills and experience in these areas.

1. Research the Company and the Position

Before the interview, it is important to research the company and the specific position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the role.

2. Prepare Answers to Common Interview Questions

There are a number of common interview questions that you can expect to be asked in an interview for a Printed Circuit Board Assembly Group Leader position. These questions may include:

- “Tell me about your experience in managing a team of assemblers.”

- “How do you ensure that PCBs are assembled according to specifications?”

- “What are some common assembly issues that you have encountered and how did you troubleshoot them?”

- “How do you maintain a safe and efficient work environment?”

3. Practice Answering Interview Questions

Once you have prepared answers to common interview questions, it is important to practice answering them out loud. This will help you to become more comfortable with the questions and to deliver your answers in a clear and concise manner.

4. Dress Professionally and Arrive on Time

It is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

5. Be Confident and Enthusiastic

During the interview, it is important to be confident and enthusiastic. This will show the interviewer that you are passionate about the position and that you believe in your abilities.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Printed Circuit Board Assembly Group Leader role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.