Feeling lost in a sea of interview questions? Landed that dream interview for Printed Circuit Board Panels Developer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Printed Circuit Board Panels Developer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

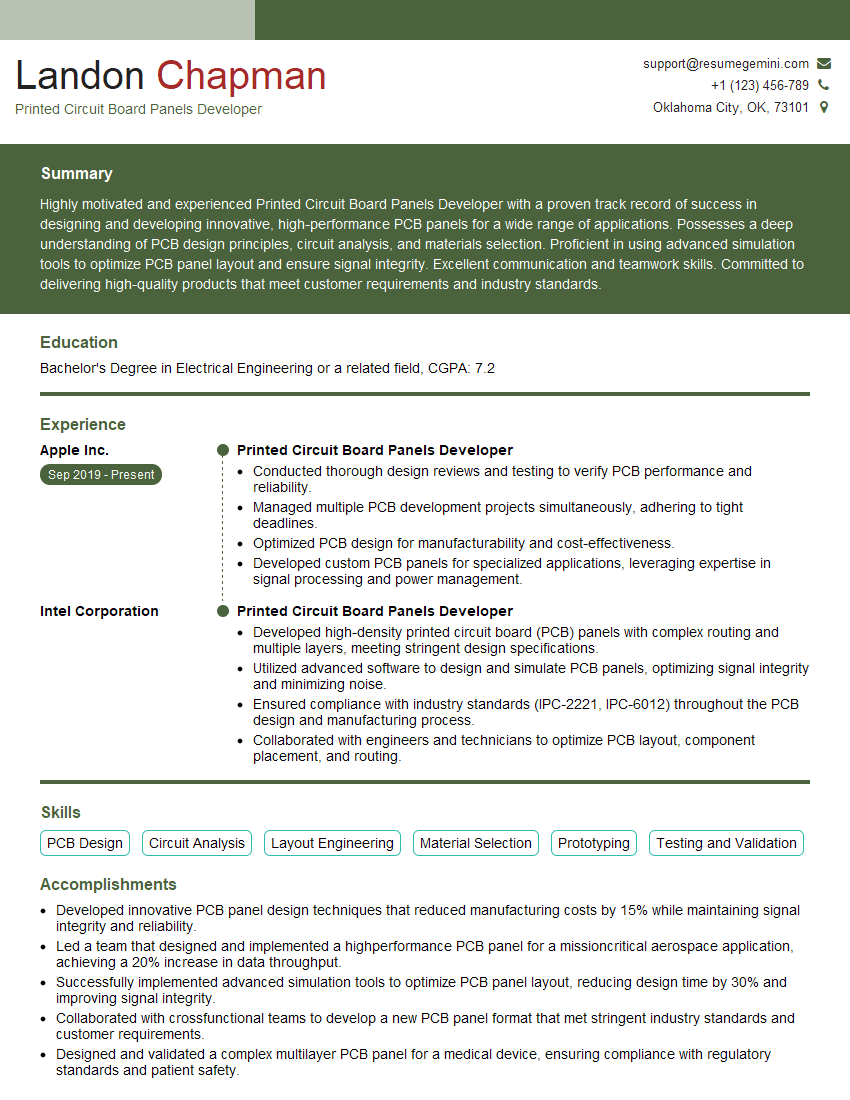

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Board Panels Developer

1. Describe the process of designing a Printed Circuit Board (PCB) Panel?

The process of designing a PCB Panel involves several steps:

- Determining Requirements: Gathering specifications and understanding the functional requirements of the PCB.

- Schematic Entry: Creating a schematic diagram that represents the electrical connections and components of the circuit.

- PCB Layout: Placing and routing the components on the PCB, ensuring proper spacing, signal integrity, and manufacturability.

- Panel Definition: Arranging multiple PCBs on a single panel to optimize material usage and fabrication efficiency.

- Artwork Generation: Creating the Gerber files (artwork) that define the physical characteristics of the PCB.

- Fabrication: Sending the artwork files to a manufacturer for PCB fabrication, which involves printing, etching, and assembling the boards.

2. Explain the factors to consider when optimizing PCB Panel utilization?

Maximizing Board Space:

- Using smaller components and leadless packages.

- Tightening component placement and routing.

- Exploring non-rectangular PCB shapes for better panel fit.

Minimizing Scrap:

- Matching PCB size to the panel dimensions.

- Using standard panel sizes and avoiding excessive panel oversizing.

- Strategically positioning PCBs on the panel to reduce wasted space.

Manufacturing Efficiency:

- Considering panel handling and assembly during the design.

- Optimizing the number of boards per panel for cost and throughput.

- Balancing component placement for even solder flow and reduced rework.

3. What are the different types of PCB layout styles, and when should each be used?

Single-layer PCB: Suitable for simple designs with few components and low complexity.

Double-layer PCB: More common, allows for increased component density and routing flexibility.

Multilayer PCB: Features multiple layers of copper, providing high component density, high-speed signal routing, and reduced crosstalk.

Rigid PCB: Made from a rigid material, suitable for high-performance applications where stability is critical.

Flexible PCB: Made from a flexible material, can withstand bending and flexing motions.

Mixed-Technology PCB: Combines different technologies, such as rigid and flexible sections, to meet specific design requirements.

4. How do you ensure signal integrity in your PCB designs?

Proper Component Placement and Routing: Minimizing trace lengths, avoiding sharp angles, and maintaining proper spacing.

Impedance Control: Matching trace widths and lengths to achieve the desired impedance for signal transmission lines.

Grounding and Shielding: Providing a solid ground plane, using proper decoupling capacitors, and incorporating shielding to minimize noise and interference.

Signal Analysis: Employing simulation tools to analyze signal integrity, predict performance, and identify potential issues before fabrication.

5. Describe the importance of thermal management in PCB design?

- Preventing Component Damage: Overheating can damage components and shorten board life.

- Maintaining Signal Integrity: High temperatures can affect signal propagation and reliability.

- Improving Reliability: Proper thermal management reduces stress on components and extends board life.

- Design Considerations: Using heat sinks, thermal vias, and copper pours for heat dissipation.

6. How do you handle design changes and revisions in the PCB development process?

- Change Management Process: Implementing a formal process for documenting, tracking, and implementing design changes.

- Collaboration and Communication: Working closely with design, manufacturing, and engineering teams to understand changes and their impact.

- Version Control: Maintaining different versions of the PCB design to track changes and facilitate rollback if necessary.

- Simulation and Verification: Running simulations and performing validations to ensure the modified design meets specifications.

7. Explain the concept of Design for Manufacturability (DFM) in PCB design?

- Component Selection: Choosing components that are widely available and easy to assemble.

- Design Rules: Adhering to manufacturing constraints, such as minimum trace widths, clearances, and component spacing.

- Testability: Designing for ease of testing, including test points and accessibility for probing.

- Solderability: Optimizing pad design and component placement for proper solderability.

- Fabricability: Considering the capabilities and limitations of the manufacturing process, such as minimum feature sizes and layer count.

8. Describe your approach to designing PCBs for high-frequency applications?

- Controlled Impedance: Accurately calculating and maintaining trace impedance to minimize signal loss and reflections.

- Signal Integrity Analysis: Employing simulation tools to analyze signal behavior, identify critical sections, and optimize routing.

- Shielding and Grounding: Utilizing shielding techniques, proper grounding, and minimizing crosstalk to maintain signal fidelity.

- Component Selection: Choosing components with low inductance and capacitance to reduce signal distortion.

- Fabrication Considerations: Collaborating with manufacturers to ensure the fabrication process supports high-frequency performance requirements.

9. How do you stay up-to-date with the latest advances in PCB design technology?

- Industry Conferences: Attending industry events and conferences to learn about new technologies and trends.

- Technical Publications: Reading technical journals, white papers, and articles to stay abreast of advancements.

- Professional Organizations: Joining professional societies, such as the IPC, to access resources and connect with industry experts.

- Online Courses and Webinars: Taking online courses or attending webinars to acquire new skills and knowledge.

- Networking: Collaborating with other PCB designers, engineers, and manufacturers to share knowledge and ideas.

10. How do you ensure the quality of your PCB designs?

- Design Reviews: Conducting thorough design reviews with peers, engineers, and manufacturers to identify potential issues.

- Simulation and Testing: Employing simulation tools and performing physical testing to verify design performance.

- Documentation and Version Control: Maintaining clear and up-to-date documentation, including design specifications, schematics, and layouts.

- Supplier Relationships: Collaborating with trusted and reliable suppliers to ensure high-quality materials and fabrication.

- Continuous Improvement: Analyzing feedback, identifying areas for optimization, and implementing ongoing improvements to enhance design quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Board Panels Developer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Board Panels Developer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printed Circuit Board Panels Developers are accountable for designing and developing printed circuit board panels, ensuring that they meet electrical and mechanical specifications and manufacturing requirements. Their key responsibilities include:

1. PCB Design and Development

Collaborate with design engineers to understand product requirements and specifications.

- Design and develop printed circuit board panels using computer-aided design (CAD) software.

- Conduct simulations and analysis to ensure board functionality, performance, and manufacturability.

- Review and modify designs to meet changing product requirements and industry standards.

2. Materials and Components Selection

Select and specify appropriate materials and components for the PCB panels, considering factors such as electrical properties, thermal conductivity, and cost.

- Research and evaluate new materials and components to improve panel performance.

- Work with suppliers to obtain high-quality materials and components at competitive prices.

3. Fabrication and Assembly Support

Provide technical guidance and support to fabrication and assembly teams to ensure the successful production of PCB panels.

- Review Gerber files and other manufacturing data to identify potential issues before fabrication.

- Assist with assembly process development and optimization to improve yield and reduce defects.

4. Quality Control and Testing

Establish and implement quality control procedures to ensure that PCB panels meet specifications and performance standards.

- Conduct electrical and functional testing to verify the integrity and functionality of PCB panels.

- Analyze test results and identify areas for improvement in design or manufacturing processes.

- Maintain accurate records of quality control data for traceability and compliance purposes.

Interview Tips

Preparing thoroughly for a Printed Circuit Board Panels Developer interview is crucial to showcasing your skills and impressing the hiring manager. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Research the specific position you are applying for, including the key responsibilities and qualifications required.

- Visit the company’s website, social media pages, and industry publications.

- Read job descriptions and articles to understand the expectations of the role.

2. Practice Your Technical Skills

Brush up on your technical skills, such as CAD software proficiency, electrical design principles, and materials science. Consider preparing examples of your previous work or projects that demonstrate your abilities.

- Review concepts related to PCB design, manufacturing, and quality control.

- Create a portfolio of your projects to showcase your technical expertise.

3. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your problem-solving abilities, teamwork skills, and work ethic. Prepare thoughtful answers that highlight your experiences and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on specific examples that demonstrate your strengths and abilities.

4. Ask Informed Questions

At the end of the interview, take the opportunity to ask thoughtful questions that show your interest in the position and the company. This demonstrates your engagement and enthusiasm for the role.

- Ask about the design process, company culture, or industry trends.

- Inquire about the company’s future plans and goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printed Circuit Board Panels Developer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.