Are you gearing up for a career in Printed Circuit Board Panels Electroless Plater? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Printed Circuit Board Panels Electroless Plater and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

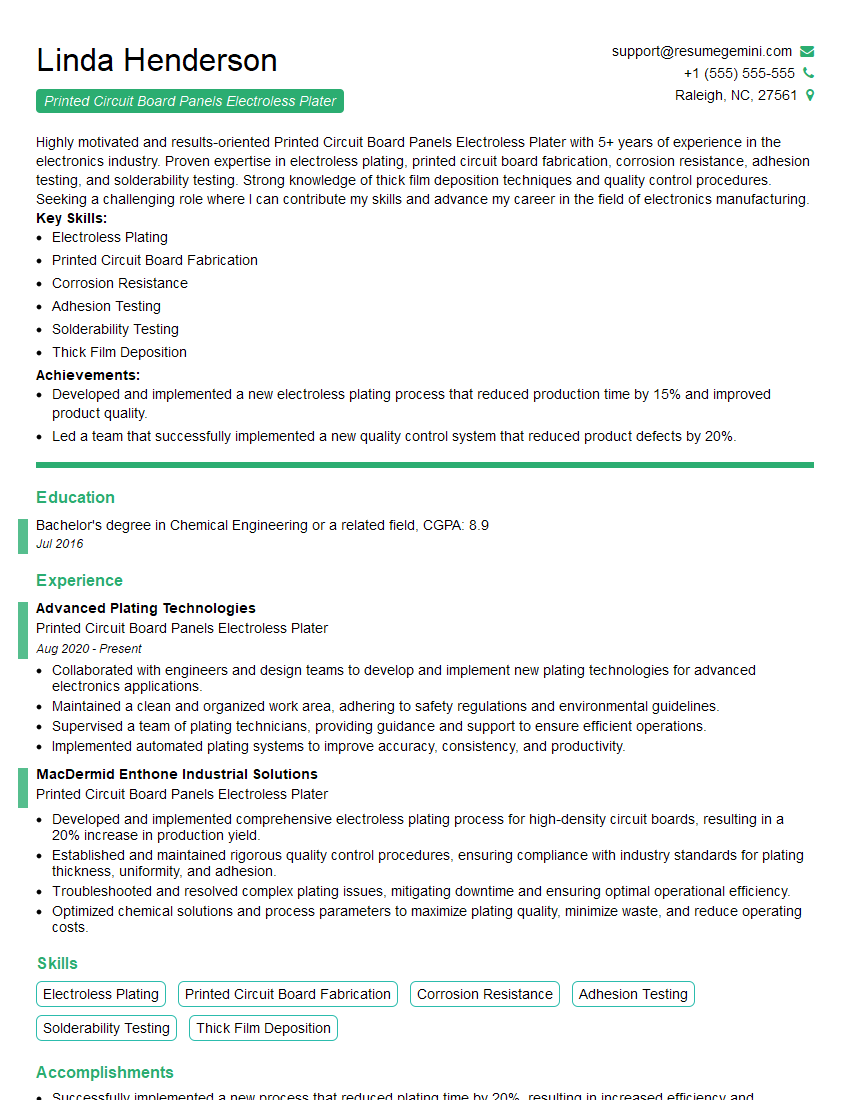

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Board Panels Electroless Plater

1. Explain the process of electroless plating on printed circuit board (PCB) panels?

- The electroless plating process involves depositing a thin layer of metal on the surface of a non-conductive material, such as a PCB panel, without the use of an external electrical current.

- It is typically used to enhance the electrical conductivity, corrosion resistance, or solderability of the PCB.

2. What are the key factors that affect the quality of electroless plating on PCB panels?

Plating Solution Composition and Maintenance:

- The composition of the plating solution, including the concentration of metal ions, reducing agents, and stabilizers, significantly influences the quality of the plating.

- Proper maintenance of the solution, such as pH control and filtration, is crucial to ensure consistent plating results.

Panel Preparation and Cleaning:

- Thorough cleaning and preparation of the PCB panels before plating is essential to remove contaminants and ensure good adhesion of the plating.

Process Parameters:

- The temperature, duration, and agitation during the plating process affect the thickness, uniformity, and quality of the plating.

3. Describe the different types of electroless plating solutions used for PCB panels and their applications.

- Acidic Electroless Copper (AEC): Widely used for through-hole plating and high-density interconnect (HDI) applications due to its ability to provide uniform and conformal coatings.

- Alkaline Electroless Copper (ALC): Used for plating on thick substrates and for applications where solderability is critical.

- Electroless Nickel (EN): Provides excellent corrosion resistance and magnetic properties, used in applications such as connectors and magnetic components.

- Electroless Gold (EG): Offers high electrical conductivity and corrosion resistance, used for contact surfaces and connectors.

4. What are the common defects associated with electroless plating on PCB panels and how can they be prevented?

- Blisters and Peeling: Caused by poor adhesion between the plating and the substrate, can be prevented by thorough cleaning and proper surface preparation.

- Nodules and Dendrites: Result from impurities in the plating solution or improper process parameters, can be minimized by maintaining solution purity and optimizing process conditions.

- Poor Coverage: Occurs when the plating solution does not reach all areas of the substrate, can be addressed by improving solution agitation or using an immersion plating technique.

5. Explain the role of quality control in electroless plating on PCB panels.

- Quality control is crucial to ensure the reliability and performance of plated PCB panels.

- It involves testing and monitoring the plating process to verify that it meets specifications for thickness, uniformity, adhesion, and other critical parameters.

- Regular testing and analysis help identify and correct any deviations from the desired process conditions.

6. Describe the equipment used for electroless plating on PCB panels.

- Plating Tank: Contains the plating solution and the PCB panels being plated.

- Agitation System: Provides agitation to ensure uniform plating and prevent the formation of defects.

- Temperature Control System: Maintains the plating solution at the desired temperature.

- Filtration System: Removes impurities from the plating solution to prevent defects.

- Analytical Equipment: Used to monitor the composition of the plating solution and test the quality of the plated panels.

7. What safety precautions are necessary when working with electroless plating solutions?

- Electroless plating solutions contain hazardous chemicals that require proper handling and disposal.

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator.

- Follow established safety protocols for handling and storing chemicals.

- Ensure proper ventilation in the plating area to minimize the risk of exposure to harmful fumes.

8. How do you stay updated with the latest advancements and best practices in electroless plating for PCB panels?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Network with other professionals in the field.

- Participate in online forums and discussion groups.

- Consult with suppliers and manufacturers for updates on new technologies and materials.

9. What are the challenges and limitations of electroless plating on PCB panels?

- Cost: Electroless plating can be more expensive than other plating methods due to the use of specialized solutions and equipment.

- Throughput: The plating process can be time-consuming, especially for large or complex panels.

- Environmental Concerns: Electroless plating solutions contain hazardous chemicals that require proper disposal, increasing environmental impact.

10. How do you handle variations in the plating process to ensure consistent quality?

- Process Monitoring: Continuously monitor the plating process parameters, such as temperature, pH, and solution composition.

- Statistical Process Control (SPC): Use SPC techniques to identify and control sources of variation in the process.

- Corrective Actions: Implement corrective actions promptly when deviations from specifications are detected.

- Continuous Improvement: Regularly review and improve the plating process to enhance quality and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Board Panels Electroless Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Board Panels Electroless Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printed Circuit Board Panels Electroless Platers are responsible for ensuring the quality and efficiency of the electroless plating process. They work in a manufacturing environment and must have a strong understanding of the electroless plating process and the equipment used to perform it. Key job responsibilities include:

1. Preparing the Printed Circuit Board Panels

This step involves cleaning and activating the panels, as well as applying a thin layer of copper. The panels must be properly prepared in order for the electroless plating process to be successful.

2. Monitoring the Electroless Plating Process

Once the panels are prepared, they are placed in an electroless plating bath. The plater must monitor the process to ensure that the plating is proceeding correctly and that the desired thickness of the plated layer is achieved.

3. Troubleshooting and Maintaining Equipment

The plater must be able to troubleshoot and maintain the equipment used in the electroless plating process. This includes identifying and resolving problems with the plating baths, the electrical system, and the other equipment used in the process.

4. Quality Control

The plater must perform quality control checks on the plated panels to ensure that they meet the required specifications. This includes measuring the thickness of the plated layer, inspecting the panels for defects, and performing electrical testing.

Interview Tips

To ace an interview for a Printed Circuit Board Panels Electroless Plater position, candidates should follow these tips:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you to understand the company’s culture, values, and goals, as well as the specific requirements of the job. You should also be familiar with the electroless plating process and the equipment used to perform it.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely during the interview.

3. Be Prepared to Discuss Your Experience and Skills

The interviewer will want to know about your experience and skills as an Electroless Plater. Be prepared to discuss your experience in detail, and highlight any specific skills or accomplishments that are relevant to the position. You should also be prepared to answer questions about your knowledge of the electroless plating process and the equipment used to perform it.

4. Ask Questions

At the end of the interview, you should have the opportunity to ask the interviewer questions. This is a great way to show that you are interested in the position and that you have done your research. Some good questions to ask include: “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”

By following these tips, candidates can increase their chances of acing an interview for a Printed Circuit Board Panels Electroless Plater position.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printed Circuit Board Panels Electroless Plater interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!