Are you gearing up for a career in Printed Circuit Board Panels Trimmer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Printed Circuit Board Panels Trimmer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

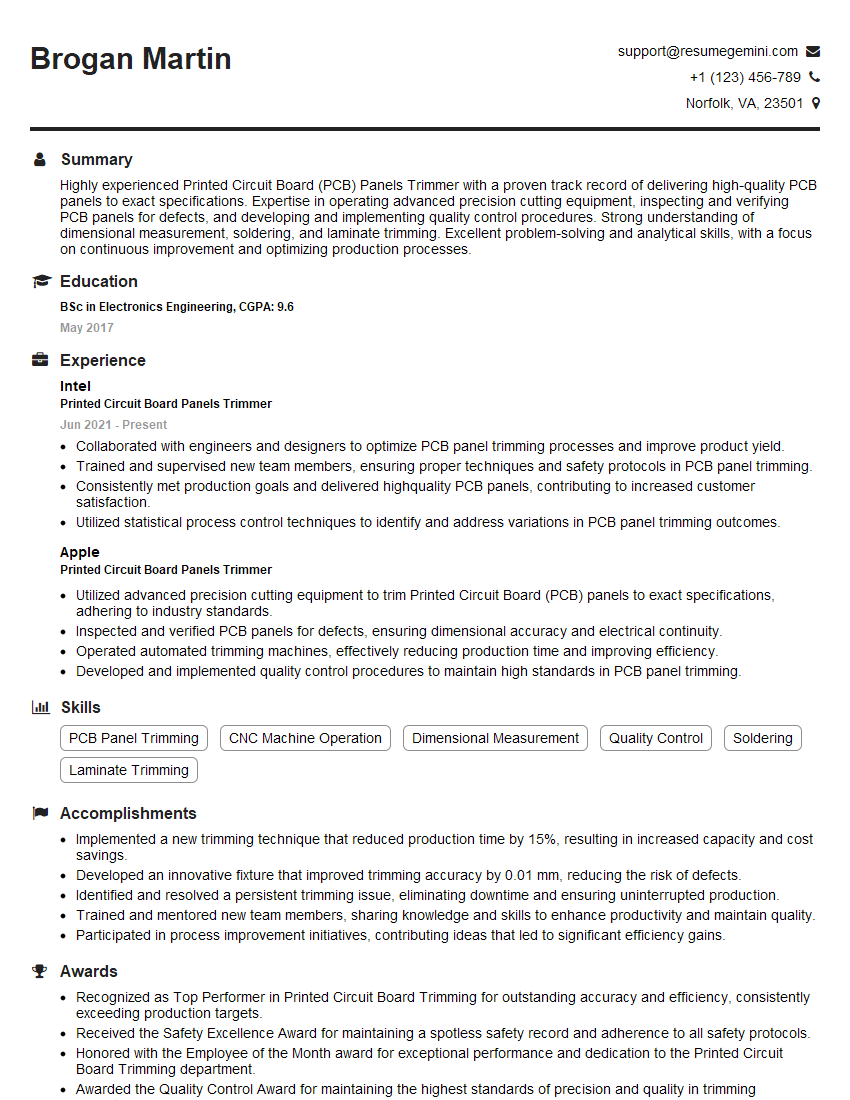

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Board Panels Trimmer

1. Explain the process of trimming Printed Circuit Board (PCB) panels?

Trimming PCB panels involves multiple steps to ensure precision and quality.

- Loading the PCB panel: The PCB panel is securely loaded onto the trimming machine, ensuring proper alignment and orientation.

- Edge detection: The machine uses sensors to detect the edges of the PCB panel, establishing reference points for trimming.

- Program selection: Based on the PCB design, the appropriate trimming program is selected, specifying the desired dimensions and tolerances.

- Trimming: The machine’s cutting tools precisely trim the PCB panel along the programmed path, removing excess material.

- Unloading: Once trimming is complete, the trimmed PCB panel is unloaded from the machine for further processing.

2. Describe the different types of trimming tools used for PCB panels?

Types of Trimming Tools

- Router bits: These are commonly used for trimming large panels, providing high precision and speed.

- Saw blades: Suitable for cutting through thicker PCB materials, offering versatility and durability.

- Laser cutters: Utilize laser technology for precise and intricate cuts, minimizing material waste.

Factors to Consider

- PCB Thickness: The thickness of the PCB material determines the appropriate tool selection.

- Trimming Speed: Different tools offer varying trimming speeds, impacting productivity.

- Accuracy and Precision: The choice of tool affects the accuracy and precision of the trimmed edges.

3. How do you ensure the accuracy and precision of trimmed PCB panels?

Ensuring accuracy and precision in trimmed PCB panels requires a combination of techniques:

- Precise Machine Calibration: Trimming machines are regularly calibrated to maintain optimal accuracy and alignment.

- Quality Tooling: Sharp and properly maintained cutting tools minimize deviations and ensure clean cuts.

- Accurate Referencing: Reference points on the PCB panel are used to align the trimming process, minimizing errors.

- Inspection and Measurement: Trimmed panels undergo rigorous inspection and measurement to verify dimensional accuracy and compliance with specifications.

4. What are the common defects that can occur during PCB panel trimming and how do you prevent them?

Common Defects

- Edge chipping: This occurs when the cutting tool applies excessive force, resulting in material breakage.

- Solder mask damage: Improper tool selection or incorrect cutting parameters can damage the solder mask layer.

- Warping: Cutting forces can cause the PCB panel to warp, affecting its flatness.

Prevention Measures

- Appropriate Tool Selection: Choosing the correct tool for the PCB material and thickness helps prevent defects.

- Optimized Cutting Parameters: Calibrating cutting speed, depth, and pressure minimizes the risk of damage.

- Proper Handling: Careful handling of PCB panels throughout the trimming process prevents warping and other defects.

5. Describe the safety precautions that should be taken when operating PCB trimming machines?

- Wear appropriate safety gear: Safety glasses, gloves, and earplugs are essential to protect against debris and noise.

- Inspect equipment regularly: Ensure that the trimming machine is in good working condition before each use.

- Keep work area clear: Remove any obstacles or loose materials to prevent accidents.

- Follow manufacturer’s guidelines: Adhere to the operating instructions and maintenance recommendations provided by the machine manufacturer.

- Be aware of potential hazards: Recognize and avoid potential hazards such as sharp edges, moving parts, and electrical hazards.

6. How do you maintain and troubleshoot PCB trimming machines?

Maintenance Schedule

- Regular cleaning: Remove debris and dust from the machine to ensure optimal performance.

- Tool inspection: Check cutting tools for wear or damage, and replace them as needed.

- Calibration: Periodically calibrate the machine to maintain accuracy and precision.

Troubleshooting

- Trimming inaccuracies: Verify tool alignment, cutting parameters, and machine calibration.

- Excessive noise or vibration: Inspect moving parts for damage or misalignment, and tighten loose components.

- Electrical faults: Check electrical connections and components for any damage or loose wires.

7. What are the key performance indicators (KPIs) that you track to measure the efficiency and effectiveness of the PCB trimming process?

- Cycle time: The average time it takes to trim a PCB panel.

- Throughput: The number of PCB panels trimmed per hour.

- Yield: The percentage of PCB panels that meet quality specifications after trimming.

- Setup time: The time it takes to prepare the machine for a new trimming job.

- Rework rate: The percentage of PCB panels that require rework due to trimming defects.

8. How do you continuously improve the PCB trimming process?

- Process analysis: Regularly review the trimming process to identify areas for improvement.

- Technology upgrades: Explore new technologies and equipment to enhance efficiency and quality.

- Training and development: Provide training opportunities for operators to improve their skills and knowledge.

- Supplier collaboration: Partner with suppliers to optimize tooling and materials for better trimming results.

- Data collection and analysis: Utilize data from the trimming process to identify trends and make data-driven decisions.

9. How do you handle different types of PCB materials and designs during trimming?

- Material considerations: Adjust cutting parameters and tooling based on the material’s thickness, hardness, and thermal properties.

- Design complexity: Analyze the design to determine the appropriate trimming strategy, considering factors such as fine features and tight tolerances.

- Custom tooling: Design and fabricate custom tooling to accommodate unique PCB shapes and features.

10. What is your understanding of the latest trends and advancements in PCB trimming technology?

- Laser trimming: Precision trimming using lasers, offering high accuracy and reduced material waste.

- Advanced automation: Integrated systems that automate loading, trimming, and unloading processes, enhancing efficiency.

- Smart monitoring: Sensors and data analytics to monitor and optimize trimming parameters in real-time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Board Panels Trimmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Board Panels Trimmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printed Circuit Board Panels Trimmers are responsible for trimming and inspecting printed circuit boards (PCBs) to ensure they meet the required specifications. Their key responsibilities include:

1. Trimming and Inspection of PCBs

Trimming involves removing excess material from the edges of the PCBs using specialized trimming machines. The trimmer ensures that the PCBs are cut to the correct size and shape, and that they meet the design specifications.

- Operate trimming machines to trim excess material from PCBs

- Inspect trimmed PCBs for defects, such as scratches, dents, or misalignment

2. Quality Control

Trimmers are responsible for maintaining the quality of the PCBs by ensuring that they meet the required tolerances and standards. They conduct thorough inspections to identify any defects or non-conformances and take corrective actions as necessary.

- Adhere to established quality control procedures and standards

- Identify and correct defects or non-conformances in trimmed PCBs

3. Equipment Maintenance

Trimmers are also responsible for maintaining the trimming machines and other equipment used in the trimming process. They perform regular maintenance tasks, such as cleaning, lubrication, and calibration, to ensure that the equipment is operating correctly and efficiently.

- Perform routine maintenance and repairs on trimming machines and related equipment

- Troubleshoot and resolve equipment malfunctions

4. Process Improvement

Trimmers are expected to continuously look for ways to improve the trimming process. They may suggest process improvements, such as optimizing machine settings or implementing new techniques, to increase efficiency and reduce defects.

- Analyze trimming processes and identify areas for improvement

- Implement process improvements to enhance efficiency and quality

Interview Tips

To ace the interview for a Printed Circuit Board Panels Trimmer position, candidates should prepare thoroughly and demonstrate their knowledge and skills.

1. Research the Company and Position

Research the company and the specific job requirements to understand their needs and expectations. This will help you tailor your answers to the specific role you are applying for.

- Visit the company’s website to learn about their business, products, and culture

- Review the job description thoroughly to identify the key skills and responsibilities required

2. Highlight Your Relevant Experience and Skills

Emphasize your relevant experience in PCB trimming and inspection, as well as any related skills or certifications you possess. Use specific examples to demonstrate your proficiency in these areas.

- Quantify your accomplishments whenever possible, using numbers and metrics to demonstrate your impact

- Be prepared to discuss your experience with different types of PCBs and trimming equipment

3. Show Your Commitment to Quality

Trimmers are responsible for maintaining the quality of PCBs, so it’s crucial to convey your commitment to quality during the interview. Highlight your attention to detail and your adherence to quality control procedures.

- Explain your understanding of quality control processes and standards

- Provide examples of how you have identified and corrected defects in the past

4. Emphasize Your Problem-solving Abilities

Trimmers may encounter various issues and challenges during the trimming process. Showcase your problem-solving abilities by providing examples of how you have successfully resolved equipment malfunctions or process-related problems.

- Describe a specific situation where you had to troubleshoot and fix a trimming machine

- Explain how you identified the root cause of a problem and implemented a solution

5. Prepare for Technical Questions

Be prepared to answer technical questions about PCB trimming and inspection processes. Study industry standards and best practices, and be ready to discuss different types of trimming machines and their applications.

- Review the principles of PCB trimming and inspection

- Familiarize yourself with common industry standards and specifications

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Printed Circuit Board Panels Trimmer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Printed Circuit Board Panels Trimmer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.