Feeling lost in a sea of interview questions? Landed that dream interview for Printed Circuit Boards Contact Printer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Printed Circuit Boards Contact Printer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

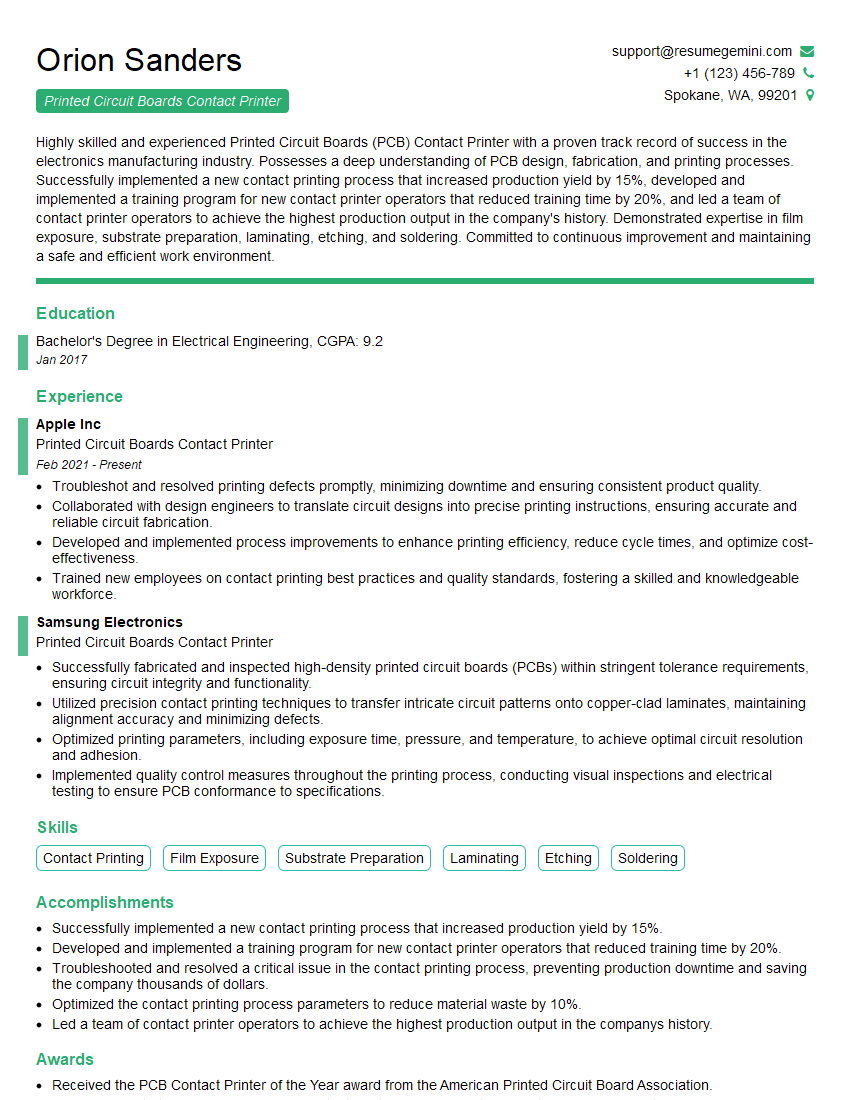

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Boards Contact Printer

1. What are the major differences between single-sided, double-sided, and multilayer printed circuit boards (PCBs)?

- Single-sided PCBs: Have copper traces on only one side of the board, with components mounted on the same side.

- Double-sided PCBs: Have copper traces on both sides of the board, allowing for more complex designs and higher component density.

- Multilayer PCBs: Consist of multiple layers of copper traces, separated by insulating material. This enables even more complex designs and allows for the integration of embedded components.

2. Describe the steps involved in the process of contact printing a PCB.

Preparing the Copper-Clad Laminate

- Clean and roughen the surface of the copper-clad laminate to improve adhesion.

- Apply a photoresist to the surface and expose it to ultraviolet light through a photomask.

Developing the Photoresist

- Develop the exposed photoresist, removing the areas that were not exposed to light.

- Rinse the board to remove any remaining photoresist and leave only the desired copper patterns.

Etching

- Etch the exposed copper using an etchant solution, such as ferric chloride or ammonium persulfate.

- Rinse the board thoroughly to remove any remaining etchant and leave the desired copper traces.

3. What types of equipment are used in the contact printing process?

- UV light source: Exposes the photoresist to ultraviolet light through a photomask.

- Vacuum frame: Holds the copper-clad laminate and photomask in place during exposure.

- Etching tank: Contains the etchant solution used to remove the unwanted copper.

- Stripping tank: Removes the photoresist after etching.

- Drying oven: Dries the board after etching and stripping.

4. How do you determine the correct exposure time for the photoresist?

- Use a test exposure to determine the optimal exposure time for the specific photoresist and light source.

- Consider factors such as the thickness of the photoresist, the intensity of the light source, and the desired resolution.

- Adjust the exposure time as needed to achieve the desired results.

5. What are the most common defects that can occur during the contact printing process, and how can they be prevented?

- Overexposure: Can cause the photoresist to become hard and difficult to remove, resulting in poor resolution.

- Underexposure: Can lead to insufficient removal of the copper during etching, resulting in weak or missing traces.

- Voids in the photoresist: Can cause breaks in the copper traces during etching.

- Contamination: Can interfere with the adhesion of the photoresist or the etching process.

6. What are the advantages and disadvantages of using a contact printer?

Advantages

- High resolution: Contact printing provides excellent resolution, allowing for the creation of precise and complex patterns.

- Low cost: Contact printing is a relatively inexpensive process compared to other PCB fabrication methods.

- Simplicity: Contact printing is a simple and straightforward process that does not require specialized equipment or materials.

Disadvantages

- Slow: Contact printing can be a slow process, especially for large or complex designs.

- Limited layer count: Contact printing is typically used for single-sided or double-sided PCBs, and is not suitable for multilayer PCBs.

- Contact defects: The direct contact between the photomask and the copper-clad laminate can lead to defects such as voids or scratches in the photoresist.

7. What is the difference between a positive and negative photoresist, and which one is used in contact printing?

- Positive photoresist: Hardens when exposed to light and is removed during the development process.

- Negative photoresist: Softens when exposed to light and is retained during the development process.

- Contact printing: Uses a positive photoresist, as the exposed areas will be removed during etching, leaving the desired copper patterns intact.

8. What are the key factors to consider when selecting a photomask for contact printing?

- Resolution: The resolution of the photomask should be high enough to achieve the desired precision in the printed patterns.

- Transparency: The photomask should be sufficiently transparent to allow the UV light to pass through and expose the photoresist.

- Material: The photomask can be made of materials such as film, glass, or quartz, each with its own advantages and disadvantages.

- Artwork: The artwork on the photomask should be accurate and free of defects, as any errors will be transferred to the PCB.

9. Describe the role of the vacuum frame in the contact printing process.

- Holds the copper-clad laminate and photomask in close contact during exposure.

- Creates a vacuum to remove air between the two surfaces, ensuring uniform contact and preventing distortions.

- Provides a stable platform for accurate and consistent exposure.

10. What are some of the common troubleshooting techniques for contact printing defects?

- Overexposure: Reduce the exposure time or use a higher-contrast photoresist.

- Underexposure: Increase the exposure time or use a lower-contrast photoresist.

- Voids in the photoresist: Clean the copper-clad laminate thoroughly before applying the photoresist, and ensure that the vacuum frame is creating a good seal.

- Contamination: Wear gloves and handle the materials carefully to avoid introducing contaminants.

- Etching problems: Check the concentration and temperature of the etchant solution, and ensure that the etching time is sufficient.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Boards Contact Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Boards Contact Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Printed Circuit Boards (PCB) Contact Printer is a skilled professional responsible for producing high-quality PCBs by transferring patterns onto copper-clad laminates using contact printing techniques.

1. Pre-production Preparation

Prepare and maintain print equipment, including developing and exposing units, vacuum frames, and contact printers.

- Calibrate and maintain equipment to ensure precise printing.

- Check and inspect incoming materials, such as photoresist, films, and laminates.

2. Contact Printing Process

Load and align photoresist-coated laminates onto printing equipment.

- Exposing laminates to ultraviolet (UV) light through phototools to transfer circuit patterns.

- Developing and rinsing laminates to remove unexposed photoresist.

3. Quality Control and Inspection

Inspect printed PCBs for defects and ensure they meet specifications.

- Use optical and electrical testing equipment to verify pattern accuracy and electrical connectivity.

- Maintain records of production and quality control data.

4. Continuous Improvement

Identify and implement process improvements to enhance efficiency and quality.

- Monitor production processes and analyze data to identify areas for optimization.

- Collaborate with team members to develop and implement solutions.

Interview Tips

Preparing thoroughly for a PCB Contact Printer interview can significantly increase your chances of success. Here are some key tips and hacks to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, culture, and the specific role you are applying for. This will enable you to tailor your answers and demonstrate your understanding of the company’s needs.

2. Highlight Your Technical Skills

PCB Contact Printing requires proficiency in operating and maintaining specialized equipment. Emphasize your expertise in developing, exposing, and processing PCBs. Quantify your accomplishments with specific examples.

3. Demonstrate Your Quality Consciousness

PCB Contact Printing demands meticulous attention to detail. Highlight your ability to adhere to strict quality standards and maintain a clean and organized work environment. Share examples of how you have identified and resolved defects.

4. Showcase Your Problem-Solving Abilities

Interviewers are interested in candidates who can think critically and solve problems. Prepare examples of how you have overcome challenges in the production process. Describe your analytical approach and the steps you took to find solutions.

- For instance, mention a time when you identified a defect in a printed PCB and implemented a process improvement to prevent future occurrences.

5. Prepare Industry-Specific Questions

Research common industry trends and advancements. Prepare thoughtful questions related to the PCB manufacturing process, equipment, or industry best practices. This shows your interest and knowledge of the field.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Printed Circuit Boards Contact Printer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Printed Circuit Boards Contact Printer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.