Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Printed Circuit Boards Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Printed Circuit Boards Inspector so you can tailor your answers to impress potential employers.

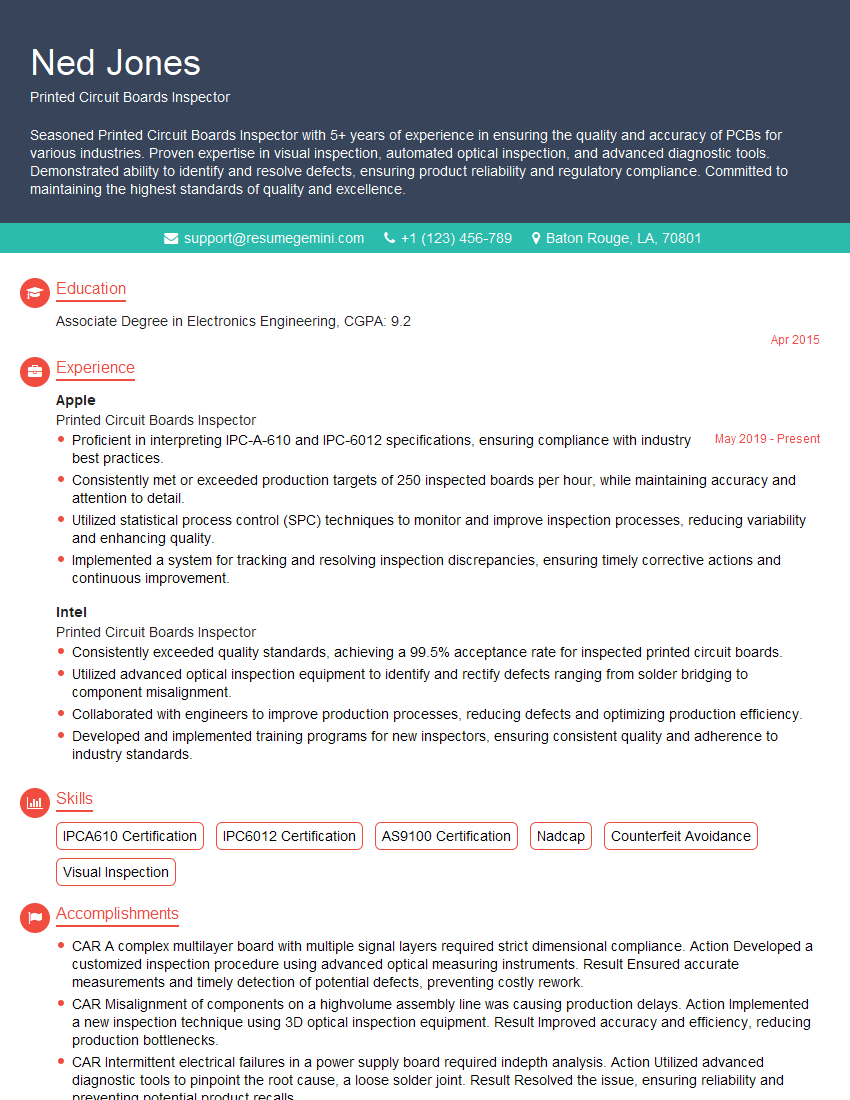

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Boards Inspector

1. How do you verify the thickness of the copper layer on a PCB?

- Use a micrometer to measure the thickness at multiple points on the board.

- Use an X-ray fluorescence (XRF) analyzer to determine the elemental composition of the copper layer.

- Use a cross-section microscope to examine the thickness and quality of the copper layer.

2. What are the different types of defects that you can identify on a PCB?

Visual defects

- Solder bridges

- Missing components

- Damaged traces

- Scratches and dents

Electrical defects

- Shorts

- Opens

- High resistance

- Ground loops

3. How do you determine the solderability of a PCB?

The solderability of a PCB can be determined by performing a solderability test. This test involves applying a flux to the board and then soldering it to a test pad. The quality of the solder joint is then inspected visually and electrically.

4. What are the different types of inspection equipment that you are familiar with?

- Optical comparators

- Automated optical inspection (AOI) machines

- X-ray inspection systems

- Scanning acoustic microscopy (SAM) systems

5. What are the most common causes of PCB failures?

- Solder joint defects

- Component defects

- Trace defects

- Environmental stress

- Aging

6. How do you ensure the quality of your inspection work?

I ensure the quality of my inspection work by following a strict quality control process. This process includes using calibrated equipment, following documented procedures, and double-checking my work. I also participate in regular training to stay up-to-date on the latest inspection techniques and standards.

7. What are the challenges of inspecting PCBs for high-volume production?

- The need for high-speed inspection

- The need to detect defects of all types and sizes

- The need to minimize false alarms

- The need to handle a variety of PCB designs and materials

8. What are the trends in PCB inspection technology?

- The use of artificial intelligence (AI) to improve defect detection

- The use of 3D inspection techniques to provide a more complete view of the PCB

- The use of non-destructive inspection techniques to avoid damaging the PCB

9. What are the key skills and qualities of a successful PCB inspector?

- Attention to detail

- Good eyesight

- Manual dexterity

- Knowledge of PCB manufacturing and inspection processes

- Ability to work independently and as part of a team

10. Why are you interested in this position?

I am interested in this position because I am passionate about quality control and I have a strong understanding of PCB manufacturing and inspection processes. I am also eager to learn new technologies and I am confident that I can make a valuable contribution to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Boards Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Boards Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printed Circuit Boards (PCBs) Inspectors play a vital role in ensuring the quality and functionality of electronic devices. Their primary responsibilities include:

1. Inspecting PCBs for Defects

Inspectors meticulously examine PCBs for any physical defects, such as:

- Solder shorts or opens

- Missing or displaced components

- Cracks or breaks in traces

2. Verifying Specifications

Inspectors ensure that PCBs meet the specified design specifications. They check dimensions, component values, and other parameters against the blueprints.

3. Using Precision Equipment

Inspectors employ various precision equipment to aid their inspection process, including:

- Magnifying glasses

- Microscopes

- Automated optical inspection (AOI) machines

4. Maintaining and Calibrating Equipment

To ensure accuracy, inspectors regularly maintain and calibrate the equipment they use. This includes cleaning lenses, replacing bulbs, and adjusting settings.

Interview Tips

Preparing for a Printed Circuit Boards Inspector interview requires a combination of technical knowledge and a strong understanding of the industry.

1. Research the Company and Role

Research the company’s products, services, and culture to demonstrate your interest and understanding of their business. Study the job description thoroughly to identify the specific skills and experience they are seeking.

2. Highlight Your Attention to Detail

Emphasize your ability to focus on minute details and identify defects that may escape the notice of others. Provide examples from previous work experience where your meticulous approach led to the detection of critical errors.

3. Demonstrate Your Technical Knowledge

Showcase your knowledge of PCBs and their manufacturing processes. Discuss the different types of PCBs, the inspection techniques you are familiar with, and the equipment you have experience using.

4. Share Industry Experience

If you have experience in the electronics manufacturing industry, highlight your familiarity with industry standards and best practices. Describe how your previous knowledge will benefit the company.

5. Practice Using Precision Equipment

If possible, practice using magnifying glasses, microscopes, or AOI machines. Familiarity with these tools will demonstrate your readiness to perform the inspection tasks effectively.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Printed Circuit Boards Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Printed Circuit Boards Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.