Feeling lost in a sea of interview questions? Landed that dream interview for Printed Circuit Boards Laminator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Printed Circuit Boards Laminator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

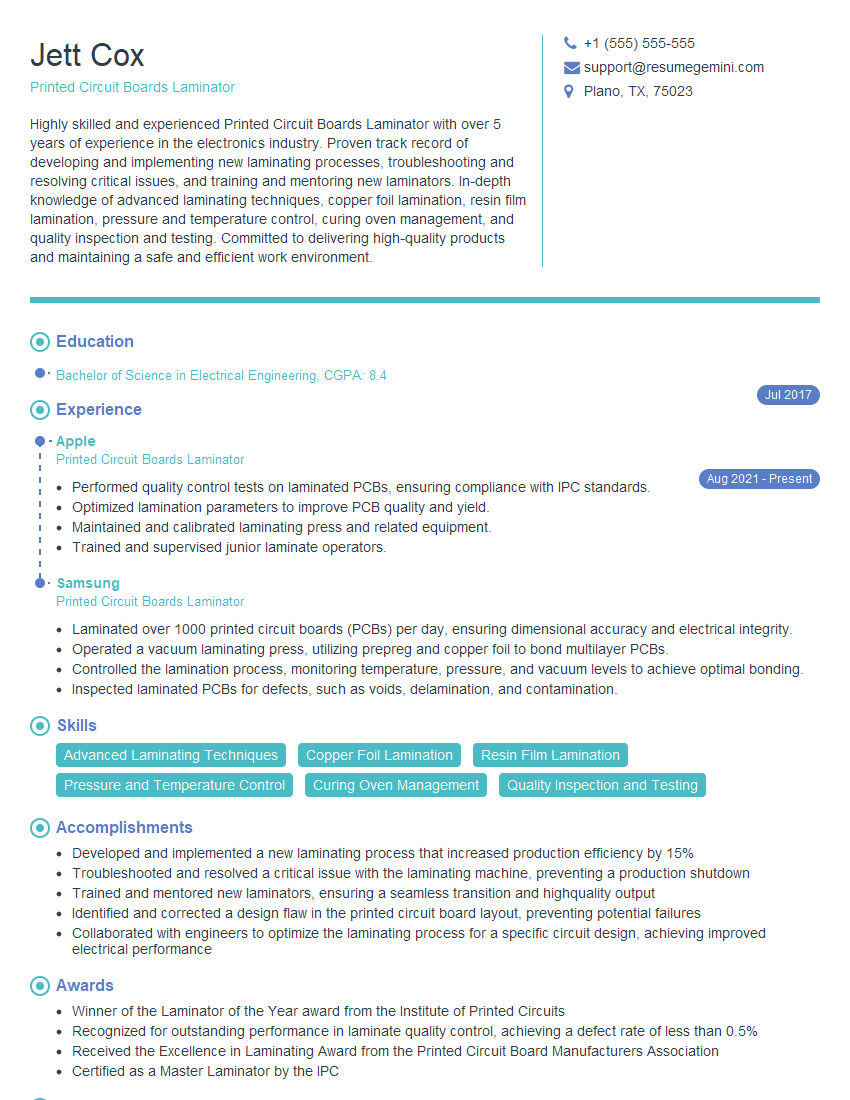

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Boards Laminator

1. What are the key factors that influence the quality of a laminated PCB?

- Material quality and characteristics (e.g., Tg, CTE, dielectric constant)

- Process parameters (e.g., temperature, pressure, time)

- Equipment calibration and maintenance

- Quality control and inspection procedures

2. Describe the different types of laminating presses used in PCB fabrication and their advantages and disadvantages.

Hydraulic presses

- High pressure, precise temperature control

- Suitable for large-scale production

- High cost, requires skilled operators

Pneumatic presses

- Lower pressure, less precise temperature control

- Compact and economical

- Not suitable for high-volume production

3. What are the main types of defects that can occur during PCB lamination and how can they be prevented?

- Delamination: Caused by insufficient adhesion between layers; prevent by optimizing process parameters and using high-quality materials

- Voids: Trapped air or gas during lamination; prevent by proper vacuum degassing and pressure control

- Warpage: Uneven expansion or contraction of layers; prevent by using balanced materials with similar CTEs

4. Explain the role of copper foil thickness in PCB lamination and how it affects the final product.

- Thicker copper foil: Lower resistance, higher current carrying capacity

- Thinner copper foil: Reduced weight, flexibility, and cost

- Optimal thickness depends on application requirements (e.g., power distribution, signal integrity)

5. What are the safety precautions that should be followed when operating a PCB laminating press?

- Wear appropriate safety gear (e.g., gloves, safety glasses)

- Check equipment calibration and maintenance regularly

- Follow manufacturer’s instructions for operation

- Handle hot laminates with care to avoid burns

6. Describe the quality control procedures used in PCB lamination and how they ensure the integrity of the final product.

- Visual inspection for defects (e.g., delamination, voids, warpage)

- Electrical testing for continuity, resistance, and capacitance

- Environmental testing for moisture resistance, thermal cycling, and vibration

- Data management and traceability to ensure compliance with customer specifications

7. How do you optimize the lamination process for different types of PCB materials (e.g., FR4, FR5, CEM-3)?

- Adjust temperature, pressure, and time based on material properties

- Use specific additives or treatments to enhance adhesion and prevent defects

- Validate process parameters through controlled experiments and data analysis

8. What troubleshooting techniques do you use to identify and resolve common problems associated with PCB lamination?

- Analyze defect patterns to determine root cause (e.g., delamination due to insufficient pressure or temperature)

- Review process parameters and make adjustments as necessary

- Consult technical manuals and refer to industry best practices

9. How do you stay updated with the latest advancements and technologies in PCB lamination?

- Attend industry conferences and workshops

- Read technical journals and research papers

- Participate in online forums and discussion groups

10. Describe your experience in working with different types of laminating equipment and materials.

- List specific presses, laminates, and materials you have worked with

- Highlight successful projects or challenges overcome

- Quantify results and demonstrate expertise (e.g., improved yield rates, reduced defects)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Boards Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Boards Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printed Circuit Boards (PCBs) Laminators play a vital role in the manufacturing of PCBs by bonding together various layers of materials, such as copper foil and fiberglass. Their responsibilities include:

1. Laminate Production

Laminators are responsible for the production of laminates, which are the foundation of PCBs. This involves selecting and preparing the appropriate materials, operating laminating presses, and monitoring the lamination process to ensure that it meets specifications.

- Selecting and preparing copper foil, fiberglass, and other materials for lamination.

- Operating laminating presses to bond the layers of materials together under heat and pressure.

- Monitoring the lamination process to ensure that it meets specifications, such as temperature, pressure, and bonding strength.

- Inspecting the finished laminates for defects and ensuring that they meet quality standards.

2. Equipment Maintenance

Laminators are also responsible for maintaining the equipment used in the lamination process. This includes regular cleaning, lubrication, and calibration of the presses and other machinery.

- Cleaning and lubricating laminating presses and other equipment.

- Calibrating presses to ensure that they are operating within specifications.

- Performing preventative maintenance to identify and address potential problems before they occur.

- Troubleshooting and repairing equipment malfunctions.

3. Quality Control

Laminators are responsible for ensuring the quality of the laminates they produce. This involves conducting inspections, testing, and analyzing the laminates to ensure that they meet customer specifications and industry standards.

- Conducting visual inspections of laminates for defects, such as voids, delamination, and contamination.

- Testing laminates for electrical and mechanical properties, such as insulation resistance, dielectric strength, and peel strength.

- Analyzing test results and making adjustments to the lamination process as needed to improve laminate quality.

- Maintaining quality records and documentation.

Interview Tips

Preparing for an interview for a Printed Circuit Boards Laminator position is essential to increase your chances of success. Here are some tips to help prepare you for the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you better understand the company’s culture, values, and the specific skills and experience they are seeking in a candidate.

- Visit the company website and social media pages to learn about their mission, products, and services.

- Read articles and news releases about the company to stay informed about their recent developments and achievements.

- Review the job description carefully to identify the key responsibilities and qualifications required for the position.

2. Highlight Your Relevant Skills and Experience

During the interview, be sure to highlight your relevant skills and experience that make you a suitable candidate for the position. This includes your technical expertise in laminate production, equipment maintenance, and quality control.

- Quantify your accomplishments and provide specific examples of your work experience to demonstrate your skills.

- If you have any certifications or training in laminate production or related fields, be sure to mention them.

- Be prepared to discuss your knowledge of industry standards and best practices for laminate production.

3. Prepare for Common Interview Questions

There are some common interview questions that you are likely to encounter during your interview. It is helpful to prepare for these questions in advance so that you can provide well-thought-out answers.

- Tell me about your experience in laminate production.

- What are your strengths and weaknesses as a laminate production technician?

- How do you ensure the quality of the laminates you produce?

- What are your career goals and how does this position fit into them?

4. Practice Your Answers

Once you have prepared your answers to common interview questions, it is helpful to practice your delivery. This will help you feel more confident and articulate during the interview.

- Rehearse your answers out loud to improve your fluency and clarity.

- Ask a friend or family member to conduct a mock interview with you to get feedback on your answers and presentation.

- Record yourself answering interview questions and watch the playback to identify areas for improvement.

5. Dress Professionally and Arrive on Time

First impressions matter, so be sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting. It is also important to arrive on time for your interview to show that you are punctual and respectful of the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printed Circuit Boards Laminator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.