Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printed Circuit Boards Numerical Control Drill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

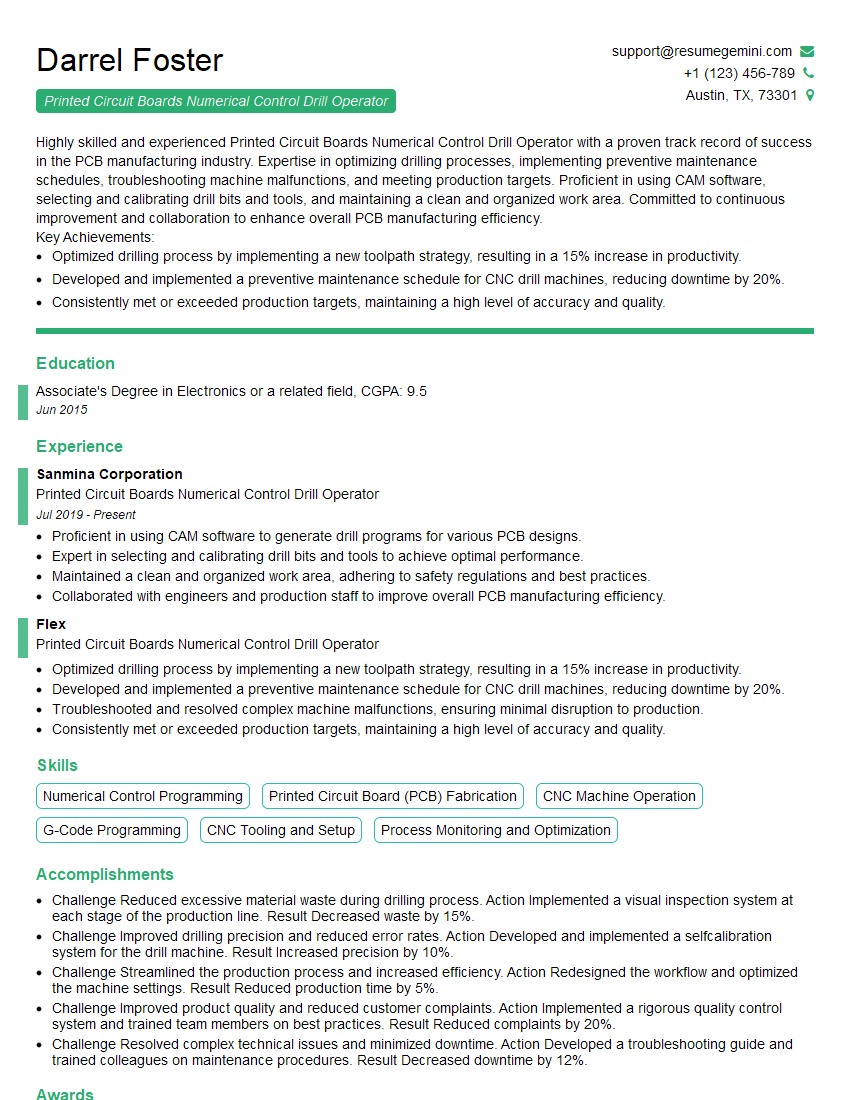

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Boards Numerical Control Drill Operator

1. How to check the accuracy of the drilling machine?

There are 5 ways to check the accuracy of the drilling machine:

- Use a precision measuring instrument like a CMM (Coordinate Measuring Machine) or a laser interferometer.

- Check the repeatability of the drilling machine by drilling multiple holes in the same location and measuring the distance between them.

- Use a test bar to check the alignment of the drilling spindle.

- Check the spindle run-out using a dial indicator.

- Inspect the drilled holes visually for any signs of misalignment or distortion.

2. How do you select the correct drill bit for a given material?

Factors to consider:

- The type of material being drilled.

- The thickness of the material.

- The desired hole size.

- The drilling speed and feed rate.

- The type of drilling machine being used.

Drill bit materials:

- High-speed steel (HSS) bits are suitable for most common materials, including steel, aluminum, and plastic.

- Carbide bits are more durable and can be used for drilling harder materials, such as stainless steel and titanium.

- Diamond bits are the most durable and can be used for drilling very hard materials, such as glass and ceramics.

3. How do you calculate the feed rate for a given drilling operation?

The feed rate is the rate at which the drill bit advances into the material. It is typically measured in millimeters per minute (mm/min) or inches per minute (in/min). The feed rate should be selected based on the following factors:

- The type of material being drilled.

- The diameter of the drill bit.

- The drilling speed.

- The desired surface finish.

The following formula can be used to calculate the feed rate:

Feed rate = (Cutting speed × Number of teeth) / (Drill diameter × Pi)

4. How do you troubleshoot a drilling machine that is not drilling holes accurately?

There are several possible reasons why a drilling machine may not be drilling holes accurately. Some common causes include:

- The drill bit is not sharp or is damaged.

- The drilling machine is not properly aligned.

- The workpiece is not properly secured.

- The drilling speed and feed rate are not correct.

- There is excessive vibration or chatter.

To troubleshoot a drilling machine that is not drilling holes accurately, the following steps should be taken:

- Inspect the drill bit and replace it if it is dull or damaged.

- Check the alignment of the drilling machine and adjust it if necessary.

- Secure the workpiece properly.

- Adjust the drilling speed and feed rate.

- Reduce vibration and chatter by using a drill press or by clamping the workpiece securely.

5. How do you maintain a drilling machine to ensure optimal performance?

Regular maintenance is essential to ensure optimal performance and longevity of a drilling machine. The following maintenance tasks should be performed on a regular basis:

- Clean the drilling machine regularly to remove dust and debris.

- Lubricate the moving parts of the drilling machine according to the manufacturer’s instructions.

- Inspect the drill bits and replace them when they become dull or damaged.

- Check the alignment of the drilling machine and adjust it if necessary.

- Check the electrical connections and ensure that they are tight and secure.

6. How do you use a coordinate measuring machine (CMM) to inspect drilled holes?

A CMM is a precision measuring instrument that can be used to inspect drilled holes for accuracy and conformance to specifications. To use a CMM to inspect drilled holes, the following steps should be taken:

- Program the CMM to measure the desired features of the drilled holes.

- Place the workpiece on the CMM table and secure it.

- Start the CMM program and allow it to measure the drilled holes.

- Analyze the CMM data to determine if the drilled holes meet the required specifications.

7. How do you program a numerical control (NC) drilling machine?

NC drilling machines are programmed using a computer program called a CAM (Computer-Aided Manufacturing) program. The CAM program generates the NC code that is used to control the drilling machine. To program an NC drilling machine, the following steps should be taken:

- Create a CAD model of the part that is to be drilled.

- Import the CAD model into a CAM program.

- Generate the NC code using the CAM program.

- Transfer the NC code to the NC drilling machine.

- Run the NC program on the drilling machine to drill the holes.

8. How do you troubleshoot a problem with a drilling machine that is not feeding properly?

There are several possible reasons why a drilling machine may not be feeding properly. Some common causes include:

- The feed motor is not working properly.

- The feed mechanism is not properly adjusted.

- There is excessive friction in the feed mechanism.

- The workpiece is not properly secured.

To troubleshoot a drilling machine that is not feeding properly, the following steps should be taken:

- Check the feed motor and ensure that it is working properly.

- Adjust the feed mechanism according to the manufacturer’s instructions.

- Reduce friction in the feed mechanism by lubricating the moving parts.

- Secure the workpiece properly.

9. How do you use a drill press to drill a hole in a printed circuit board (PCB)?

To use a drill press to drill a hole in a PCB, the following steps should be taken:

- Select the appropriate drill bit for the size of the hole that is to be drilled.

- Secure the PCB to the drill press table.

- Align the drill bit with the center of the hole that is to be drilled.

- Start the drill press and slowly lower the drill bit into the PCB.

- Drill the hole to the desired depth.

- Stop the drill press and raise the drill bit out of the PCB.

10. How do you calculate the drilling speed for a given material?

The drilling speed is the rate at which the drill bit rotates. It is typically measured in revolutions per minute (RPM). The drilling speed should be selected based on the following factors:

- The type of material being drilled.

- The diameter of the drill bit.

- The desired surface finish.

The following formula can be used to calculate the drilling speed:

Drilling speed = (Cutting speed × 3.14) / Drill diameter

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Boards Numerical Control Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Boards Numerical Control Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A printed circuit boards numerical control drill operator is responsible for operating a numerical control (NC) drill machine to drill holes in printed circuit boards (PCBs). The operator must be able to read and interpret engineering drawings and follow written instructions. They must also be able to set up and operate the NC drill machine and monitor its operation. In addition, the operator must be able to inspect PCBs for defects and make repairs as necessary.

1. Set up and operate NC drill machine

The operator must be able to set up and operate the NC drill machine according to the engineering drawings. This includes loading the PCB into the machine, setting the drilling parameters, and starting the drilling process.

- Load the PCB into the machine

- Set the drilling parameters

- Start the drilling process

2. Monitor the operation of the NC drill machine

The operator must monitor the operation of the NC drill machine to ensure that it is drilling the holes correctly. This includes watching for any errors or defects in the PCBs.

- Watch for any errors or defects in the PCBs

- Stop the drilling process if any errors or defects are found

3. Inspect PCBs for defects

The operator must inspect the PCBs for defects after they have been drilled. This includes checking for any missing or misaligned holes, as well as any other defects that could affect the performance of the PCB.

- Check for any missing or misaligned holes

- Check for any other defects that could affect the performance of the PCB

4. Make repairs to PCBs

The operator must be able to make repairs to PCBs if any defects are found. This includes soldering new components onto the PCB, repairing broken traces, and replacing damaged components.

- Solder new components onto the PCB

- Repair broken traces

- Replace damaged components

Interview Tips

Here are some tips to help you ace your interview for a printed circuit boards numerical control drill operator position:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the position.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice answering these questions in a clear and concise way.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you take the interview seriously.

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are taking the interview seriously.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Printed Circuit Boards Numerical Control Drill Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.