Are you gearing up for an interview for a Printed Circuit Boards Solder-Leveler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Printed Circuit Boards Solder-Leveler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

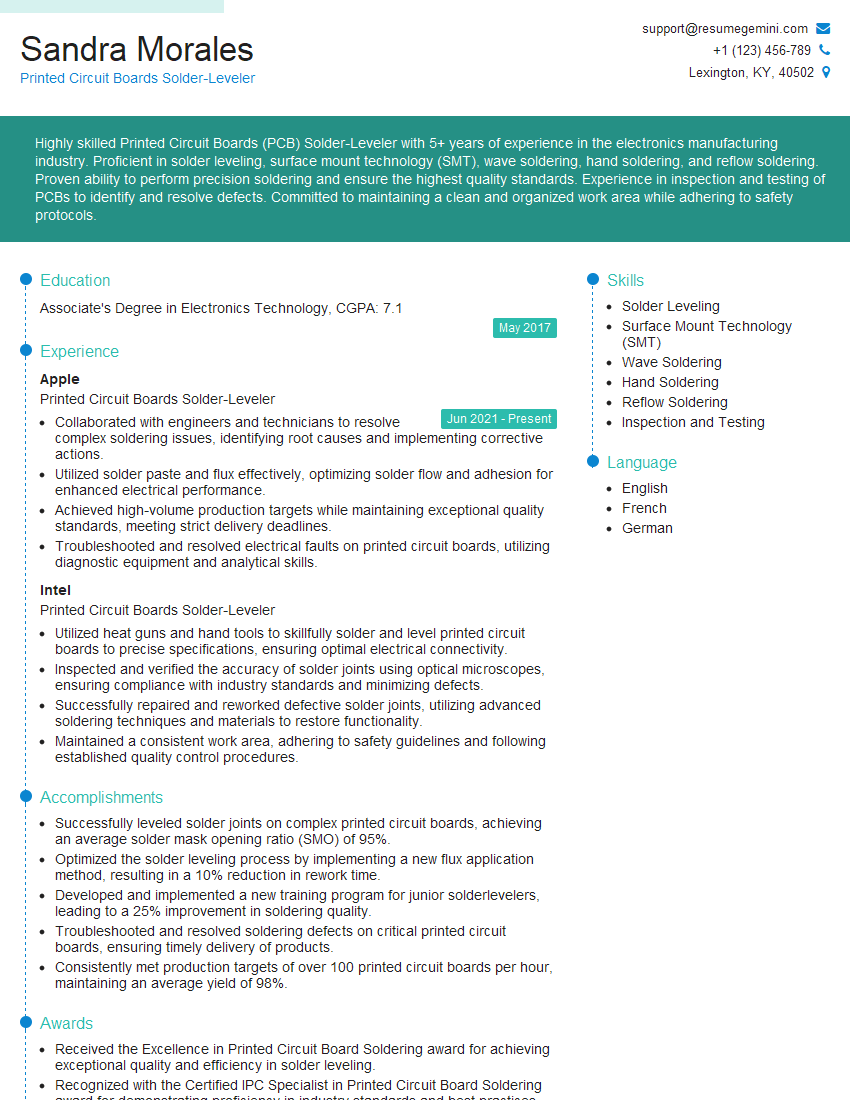

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printed Circuit Boards Solder-Leveler

1. What is the purpose of a solder leveler in PCB assembly?

A solder leveler is a machine used in PCB assembly to flatten and smooth the solder joints on a printed circuit board (PCB). It ensures consistent solder joint height and eliminates excess solder, improving the reliability and performance of the PCB.

2. Describe the different types of solder levelers and their advantages and disadvantages.

Infrared Leveler

- Uses infrared radiation to heat and melt the solder.

- Advantages: Non-contact process, precise temperature control.

- Disadvantages: Expensive, can damage heat-sensitive components.

Hot Air Leveler

- Utilizes hot air to melt the solder.

- Advantages: Affordable, easy to use.

- Disadvantages: Less precise than infrared, can cause component displacement.

3. What are the key parameters to consider when setting up a solder leveler?

Key parameters to consider include:

- Temperature: Setting the correct temperature for the solder alloy used.

- Speed: Determining the optimal speed at which the leveler moves over the PCB.

- Height: Adjusting the distance between the leveler and the PCB to achieve desired solder joint height.

- Dwell Time: Controlling the duration during which the leveler remains over each solder joint.

4. How do you troubleshoot common solder leveling defects, such as solder bridging, solder voids, and cold joints?

- Solder Bridging: Adjust temperature, speed, or dwell time to minimize solder flow.

- Solder Voids: Increase temperature, reduce speed, or adjust height to ensure proper wetting.

- Cold Joints: Check for contamination, increase temperature, or extend dwell time.

5. What are the safety precautions to consider when operating a solder leveler?

- Wear appropriate protective gear (gloves, safety glasses, lab coat).

- Ensure proper ventilation to avoid exposure to solder fumes.

- Use grounded equipment to prevent electrical shock.

- Follow manufacturer’s safety instructions and guidelines.

6. How do you maintain and calibrate a solder leveler?

Maintenance and calibration typically involve:

- Regular cleaning of the leveler head and nozzles.

- Checking and replacing worn or damaged parts.

- Calibrating the temperature and height settings according to the manufacturer’s specifications.

7. What are the different types of solder pastes used in PCB assembly?

- Lead-Free Solder Paste: RoHS-compliant, contains no lead.

- Leaded Solder Paste: Contains lead, offers higher wettability.

- Water-Washable Solder Paste: Easy to clean, flux residues can be removed with water.

- No-Clean Solder Paste: Flux residues do not require cleaning.

8. How do you determine the correct solder paste stencil thickness for a given PCB?

The stencil thickness depends on the component size and pitch:

- For fine-pitch components (0.4mm or less), a stencil thickness of 0.1mm to 0.127mm is recommended.

- For medium-pitch components (0.5mm to 1mm), a stencil thickness of 0.127mm to 0.152mm is suitable.

- For large-pitch components (over 1mm), a stencil thickness of 0.152mm to 0.2mm can be used.

9. How do you identify and fix solderability issues on PCBs?

- Solder Balling: Check for contamination, adjust stencil thickness, or use a different solder paste.

- Solder Skipping: Ensure proper component placement, clean the PCB surface, or optimize the reflow profile.

- Solder Bridging: Adjust reflow temperature, stencil thickness, or solder paste volume.

10. What are the latest trends and advancements in solder leveling technology?

- Laser-Based Leveling: Uses lasers to precisely melt and reshape solder joints.

- 3D Solder Leveling: Provides precise control over solder joint height and shape.

- Automated Solder Leveling Systems: Integrated with PCB assembly lines for increased efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printed Circuit Boards Solder-Leveler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printed Circuit Boards Solder-Leveler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Printed Circuit Boards Solder-Leveler is responsible for ensuring the quality and reliability of printed circuit boards (PCBs) by leveling the solder on the boards. They work closely with other members of the production team to ensure that PCBs meet all specifications

1. Solder Leveling

This involves removing excess solder from the boards and ensuring that the solder joints are smooth and even. They may use a variety of tools and techniques to achieve this, such as scrapers, brushes, and hot air guns.

- Inspect PCBs for solder defects.

- Use a solder leveler to remove excess solder and smooth solder joints.

- Check the quality of the solder joints and make any necessary repairs.

2. Quality Control

Solder-Levelers are also responsible for inspecting PCBs for defects. They may use a variety of techniques to do this, such as visual inspection, electrical testing, and X-rays. They must be able to identify and correct any defects that they find.

- Inspect PCBs for defects, such as solder bridges, shorts, and opens.

- Repair or rework PCBs to correct defects.

- Document all repairs and rework.

3. Process Improvement

Solder-Levelers may also be involved in process improvement. They may work with other members of the production team to identify areas where the process can be improved. They may also develop and implement new procedures to improve the quality and efficiency of the process.

- Identify areas for process improvement.

- Develop and implement new procedures.

- Train other employees on new procedures.

4. Customer Service

Solder-Levelers may also be responsible for providing customer service. They may work with customers to resolve any issues they have with PCBs. They may also provide technical support to customers.

- Respond to customer inquiries and complaints.

- Provide technical support to customers.

- Resolve customer issues.

Interview Tips

Preparing for an interview for a Printed Circuit Boards Solder-Leveler position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the position.

- Visit the company website and read about their mission, products, and services.

- Read the job description carefully and identify the key responsibilities of the position.

- If possible, talk to someone who currently works at the company.

2. Practice Your Answers

Once you have researched the company and position, it is important to practice your answers to common interview questions. This will help you to feel more confident and prepared during the interview.

- Use the STAR method (Situation, Task, Action, Result) to answer questions.

- Practice your answers out loud so that you can deliver them smoothly.

- Ask a friend or family member to help you with a mock interview.

3. Prepare Questions

At the end of the interview, you will likely be given the opportunity to ask questions. This is a great opportunity to show your interest in the position and the company. It is also a chance to learn more about the company and the position.

- Prepare a few questions about the company, the position, and the industry.

- Ask questions that are specific to the company and the position.

- Avoid asking questions that are too general or that can be easily answered by researching the company.

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothing that is appropriate for a business setting.

- Dress in a suit or business casual attire.

- Make sure your clothes are clean and wrinkle-free.

- Accessorize with a tie or scarf, if desired.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printed Circuit Boards Solder-Leveler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.