Feeling lost in a sea of interview questions? Landed that dream interview for Printer’s Devil but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Printer’s Devil interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

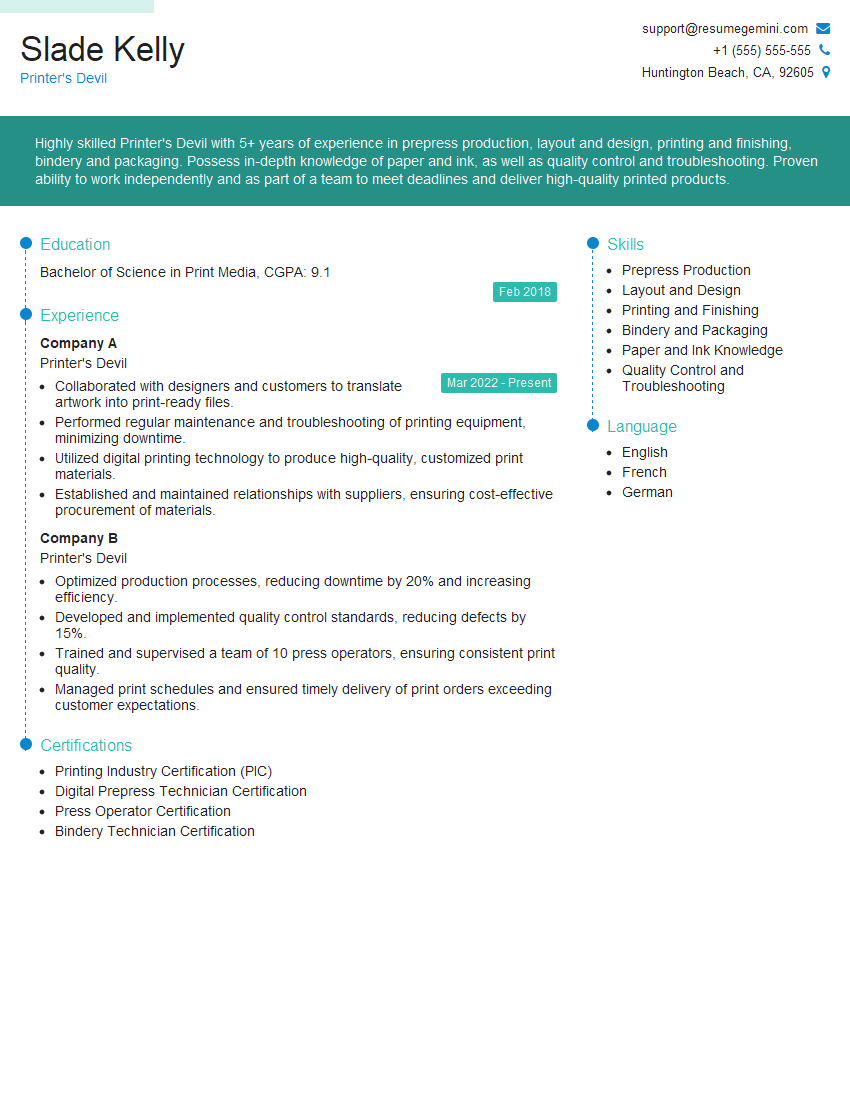

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printer’s Devil

1. What are the different printing processes and which one is best suited for a particular job?

There are various printing processes, each with its advantages and disadvantages. Here are some common types:

- Offset printing: High-quality, cost-effective for large quantities.

- Digital printing: Quick and flexible, suitable for short runs and variable data.

- Flexography: Durable and cost-effective, ideal for packaging and labels.

- Gravure printing: Excellent print quality, used for high-volume jobs like magazines.

- Screen printing: Durable and vibrant colors, suitable for textiles and specialty prints.

The best process depends on factors such as the desired quality, quantity, and budget.

2. What are the key factors to consider when selecting paper for a print job?

Paper stock

- Weight: Thickness of paper measured in gsm or lb.

- Type: Coated, uncoated, glossy, matte, etc.

- Opacity: How well paper prevents light from passing through.

Print quality

- Finish: Smoothness or texture of paper.

- Brightness: Reflectance of light.

- Ink absorption: Ability to absorb and hold ink.

Cost and availability

- Price: Cost per sheet or ream.

- Availability: Ease of obtaining the desired paper.

3. How do you ensure color accuracy and consistency in printing?

Color accuracy is crucial. Here’s how to achieve it:

- Calibrate printing equipment: Regularly adjust devices to produce accurate colors.

- Use color profiles: Create and apply profiles to match colors between different devices.

- Proof prints: Print samples to check color accuracy before large-scale printing.

- Monitor and adjust ink levels: Ensure ink cartridges or tanks are full and ink flow is consistent.

- Communicate with clients: Establish clear color expectations and provide accurate color proofs.

4. What steps do you take to troubleshoot printing problems effectively?

- Identify the problem: Determine the nature of the issue, such as print quality, alignment, or paper jams.

- Gather information: Check error messages, inspect the print job, and review recent changes made to the printer.

- Consult resources: Refer to user manuals, online forums, or contact the manufacturer for guidance.

- Test and eliminate: Try simple solutions such as cleaning print heads or replacing ink cartridges.

- Seek professional help: If the issue persists, consider contacting a technician to diagnose and repair the printer.

5. How do you handle emergencies or unexpected situations during the printing process?

- Stay calm and assess the situation: Determine the severity of the issue and its potential impact.

- Communicate with clients: Inform them about the issue and provide an estimated time for resolution.

- Prioritize tasks: Focus on resolving critical issues that may delay production.

- Delegate and collaborate: If necessary, assign tasks to colleagues or seek assistance from other departments.

- Document and learn: Record the incident, identify its cause, and implement measures to prevent similar issues in the future.

6. What techniques do you use to improve efficiency and reduce waste in the printing process?

- Job planning: Optimize the print schedule to minimize downtime and maximize productivity.

- Ink and paper management: Monitor ink levels and paper usage to avoid costly overruns and shortages.

- Digital proofing: Use digital proofs to reduce physical printing for approvals and corrections.

- Automated processes: Implement automated tasks like color correction and imposition to save time and reduce errors.

- Regular maintenance: Perform preventive maintenance to minimize breakdowns and ensure smooth operation.

7. How do you stay up-to-date with the latest printing technologies and trends?

- Attend industry events and conferences: Learn about new technologies and network with experts.

- Read trade publications and online resources: Stay informed about industry advancements and best practices.

- Participate in online forums and discussions: Engage with other professionals to share knowledge and solve problems.

- Take advantage of training and certification programs: Enhance skills and gain recognized credentials.

- Collaborate with equipment manufacturers and vendors: Learn about emerging technologies and receive technical support.

8. What is your understanding of prepress and postpress processes? How do they impact print quality?

Prepress:

- File preparation: Ensuring print-ready files.

- Color correction: Adjusting colors for accurate reproduction.

- Imposition: Arranging pages for efficient printing.

Postpress:

- Binding: Combining printed pages into a finished product.

- Trimming and folding: Shaping the printed material.

- Finishing: Adding special effects like laminating or varnishing.

Each step impacts print quality. Errors in prepress can lead to misaligned colors or text, while poor postpress handling can damage the finished product.

9. Can you describe the role of a Printer’s Devil in a printing environment?

- Assisting with prepress tasks like file preparation and color correction.

- Preparing printing plates and operating printing presses.

- Monitoring print quality and making adjustments as needed.

- Performing postpress operations like binding, trimming, and finishing.

- Maintaining equipment and ensuring a clean and organized work environment.

10. Why are you interested in working as a Printer’s Devil?

I have always been fascinated by the printing process and the precision involved in creating high-quality printed materials. As a Printer’s Devil, I am eager to learn from experienced professionals, contribute to the efficient operation of the printing environment, and develop the skills necessary to excel in this field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printer’s Devil.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printer’s Devil‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities: Printer’s Devil

A Printer’s Devil, also known as a Printer’s Apprentice, is an entry-level position in the printing industry where the primary responsibility is to assist and learn from experienced printers. This role plays a vital role in supporting the smooth functioning of printing operations.

1. Assisting in Printing Processes

Assisting in the setup and operation of printing equipment, including presses, cutters, and bindery machines.

- Load and unload paper stock, ensuring proper alignment and tension.

- Monitor printing operations, ensuring quality and efficiency.

2. Maintenance and Cleaning

Performing regular maintenance tasks on printing equipment, such as cleaning, oiling, and replacing parts.

- Maintain a clean and organized work area.

- Inspect equipment for any signs of damage or malfunction.

3. Materials Handling

Handling and transporting materials used in the printing process, such as paper, ink, and plates.

- Load and unload paper stock from storage areas.

- Handle and dispose of hazardous materials, such as inks and solvents.

4. Learning and Development

Actively seeking opportunities to learn and develop skills in the printing industry.

- Observe and assist experienced printers to gain knowledge and technical expertise.

- Participate in training programs and workshops to enhance skills.

Interview Preparation Tips for Printer’s Devil

Preparing for an interview for a Printer’s Devil position requires a combination of research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Thoroughly research the printing company you are applying to. Understand their history, services, and industry standing. Familiarize yourself with the latest trends and technologies in the printing industry.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice answering these questions out loud to build confidence and structure your answers effectively.

- Why are you interested in a career in the printing industry?

- What are your strengths and weaknesses as a potential Printer’s Devil?

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience, even if they are not directly related to printing. Focus on transferable skills such as attention to detail, problem-solving, and teamwork.

- Showcase any experience in handling materials or working in a manufacturing environment.

- Mention any coursework or training you have taken in printing or related fields.

4. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview, arrive on time, and maintain a positive and professional demeanor throughout the process.

- Choose attire that is clean, pressed, and fits comfortably.

- Plan your route and allow ample time for transportation.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions about the company, the role, and the industry. This shows your interest and engagement in the opportunity.

- Inquire about the company’s growth plans and future projects.

- Ask about the training and development opportunities available for Printer’s Devils.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printer’s Devil interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!