Are you gearing up for a career in Printing Plate Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Printing Plate Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

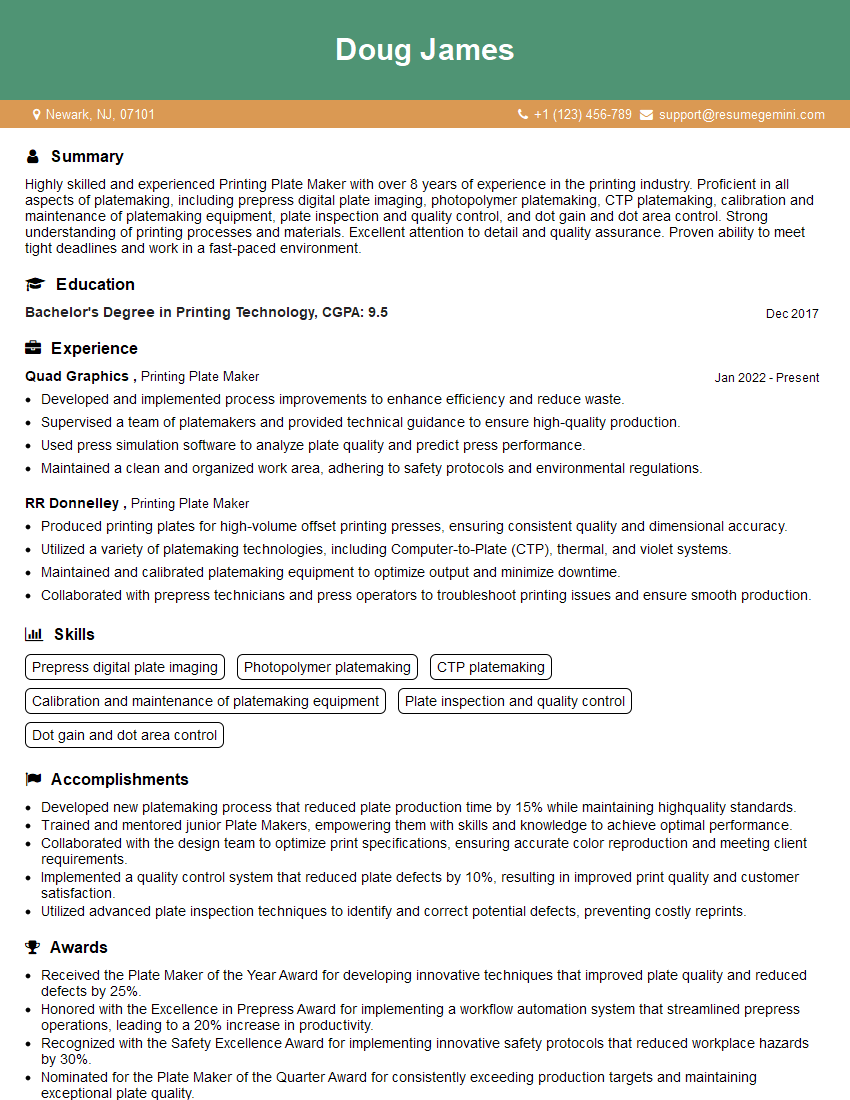

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printing Plate Maker

1. What is the difference between positive and negative plates?

Positive plates are made of a photosensitive material that is exposed to light and then developed to create the image. The unexposed areas of the plate will be etched away, leaving the exposed areas as raised areas that will transfer ink to paper. Negative plates are made of a material that is not photosensitive and is instead exposed to light through a negative of the image. The exposed areas of the plate will be etched away, leaving the unexposed areas as raised areas that will transfer ink to paper.

- Positive plates are used for printing on paper that is not coated, while negative plates are used for printing on paper that is coated.

- Positive plates are less expensive and are more easily made, while negative plates are more durable and produce higher-quality prints.

2. What are the different types of printing plates?

Metal Plates

- Most common type of printing plate

- Made of aluminum, zinc, or copper

- Durable and can be used for long print runs

Polymer Plates

- Made of a flexible plastic material

- Less durable than metal plates but are less expensive

- Used for short print runs and for printing on a variety of surfaces

Letterpress Plates

- Used for printing on paper, metal, or other substrates

- Made of a hard material such as steel or brass

- Durable and can be used for long print runs

3. What is the process of making a printing plate?

The process of making a printing plate involves several steps:

- Creating a digital image of the artwork

- Transferring the image to a photosensitive plate

- Exposing the plate to light

- Developing the plate

- Etching the plate

- Finishing the plate

4. What are the common problems that can occur during plate making?

Several common problems can occur during plate making, including:

- Underexposure: When the plate is not exposed to enough light, the image will be weak and faint.

- Overexposure: When the plate is exposed to too much light, the image will be too dark and muddy.

- Scratches: Scratches on the plate can cause lines or streaks to appear in the printed image.

- Dents: Dents in the plate can cause white spots to appear in the printed image.

- Contamination: Contamination of the plate with dust or other particles can cause spots or streaks to appear in the printed image.

5. What are the different types of platemaking equipment?

Several different types of platemaking equipment are available, including:

- Platemaking machines: These machines are used to create printing plates from digital images.

- Exposure units: These units are used to expose printing plates to light.

- Developing machines: These machines are used to develop printing plates.

- Etching machines: These machines are used to etch printing plates.

- Finishing machines: These machines are used to finish printing plates.

6. What are the important factors to consider when choosing a platemaking system?

Several important factors to consider when choosing a platemaking system include:

- The type of printing press being used

- The size and complexity of the images being printed

- The desired print quality

- The budget available

7. What are the latest trends in platemaking technology?

Several of the latest trends in platemaking technology include:

- Computer-to-plate (CTP) technology: This technology allows printing plates to be created directly from digital files, eliminating the need for film.

- Thermal platemaking: This technology uses heat to create printing plates, which is faster and more efficient than traditional methods.

- Waterless platemaking: This technology uses a waterless process to create printing plates, which reduces waste and improves print quality.

8. What are the environmental concerns associated with platemaking?

Several environmental concerns are associated with platemaking, including:

- The use of hazardous chemicals: Many of the chemicals used in platemaking are hazardous to human health and the environment.

- The generation of wastewater: Platemaking generates wastewater that can contain hazardous chemicals.

- The disposal of spent plates: Spent printing plates can be hazardous waste and must be disposed of properly.

9. What are the safety precautions that should be taken when working with platemaking chemicals?

Several safety precautions should be taken when working with platemaking chemicals, including:

- Wearing appropriate personal protective equipment (PPE): This includes gloves, eye protection, and a respirator.

- Working in a well-ventilated area: This will help to prevent the inhalation of hazardous fumes.

- Following the manufacturer’s instructions for use: This will help to ensure that the chemicals are used safely and effectively.

- Disposing of chemicals properly: This will help to protect the environment.

10. What are the quality control procedures that should be followed during platemaking?

Several quality control procedures should be followed during platemaking, including:

- Inspecting the plates for defects: This should be done before and after exposure, development, and etching.

- Measuring the plate thickness: This will help to ensure that the plates are the correct thickness for the printing press being used.

- Testing the plates on a press: This will help to ensure that the plates are printing correctly before they are used for a production run.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printing Plate Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printing Plate Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Printing Plate Makers are the backbone of the printing process, responsible for creating the printing plates that transfer images and text onto paper. The key job responsibilities of a Printing Plate Maker include:

1. Preparing Printing Plates

- Prepare printing plates by cleaning, coating, and sensitizing them for imaging.

- Set up and operate platemaking equipment to produce high-quality printing plates.

2. Imaging Plates

Using computer-to-plate (CTP) or traditional methods, expose printing plates to light or lasers to create the desired images.

- Control the exposure time and intensity to achieve accurate and consistent results.

- Develop and finish the exposed plates using chemicals and equipment.

3. Quality Control

Inspect and evaluate printing plates for defects, such as scratches, pinholes, or uneven exposure.

- Make adjustments to the platemaking process to ensure the production of high-quality plates.

- Maintain accurate records of plate production and quality control.

4. Collaboration

Collaborate with other printing professionals, such as press operators and graphic designers, to ensure the smooth production of printed materials.

- Provide technical support and troubleshooting assistance to colleagues.

- Stay up-to-date on the latest printing technologies and trends.

Interview Tips

1. Research the Company and Industry

- Learn about the company’s history, products, and services.

- Research the printing industry and current trends to show your knowledge and interest.

- Practice answering questions about your understanding of the industry and how you can contribute to the company.

2. Highlight Relevant Skills and Experience

- Emphasize your technical expertise in platemaking, including experience with different types of equipment and processes.

- Showcase your understanding of image processing, color management, and quality control techniques.

- Provide specific examples of successful projects where you demonstrated your skills.

3. Prepare for Common Interview Questions

- Practice answering questions about your knowledge of printing materials, processes, and equipment.

- Prepare to discuss your experience with troubleshooting and problem-solving in a printing environment.

- Be ready to explain how your skills and experience make you a suitable candidate for the role.

4. Ask Intelligent Questions

- Ask thoughtful questions about the company’s printing operations, technology, and growth plans.

- Inquire about the company’s commitment to quality and innovation.

- Show your interest in the role and how you can contribute to the team’s success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Printing Plate Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.